Description

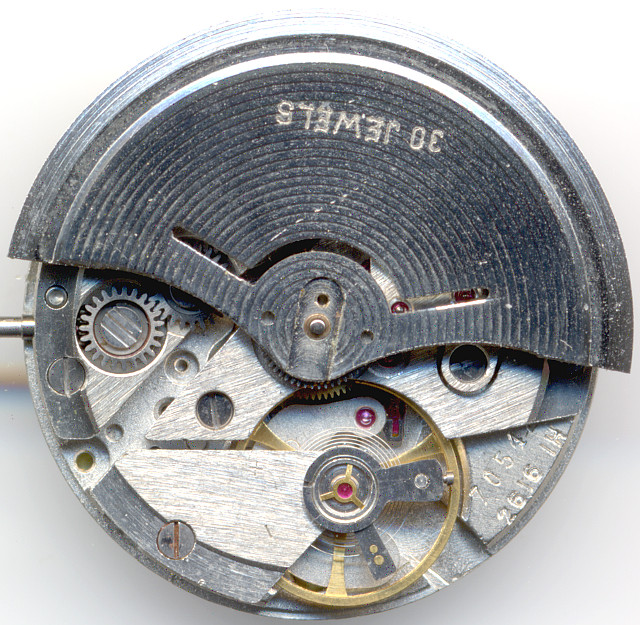

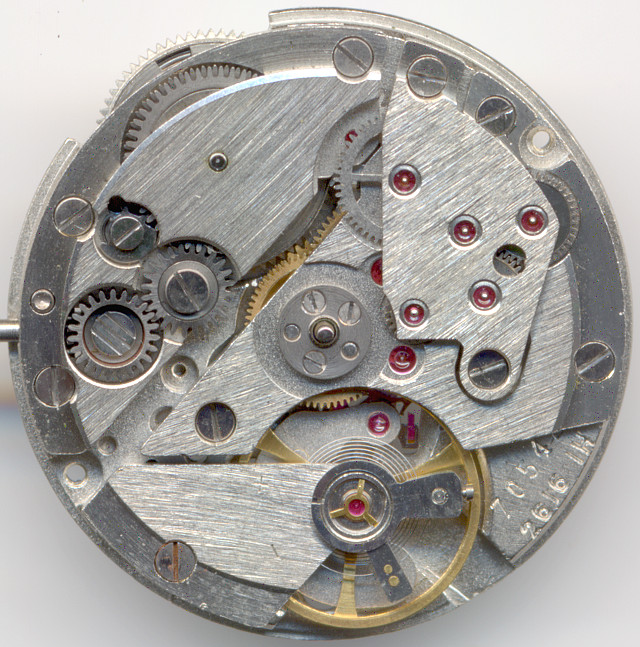

This selfwinding movement was put into “Meister-Anker” watches in the seventies, sold by the german “Quelle” shop. The high amount of 30 jewels is remarkable, and no less than twelve of them are used for the selfwinding mechanism. Such an effort is hard to find elsewhere.

The Poljot 2616.1H was (as caliber 2616H) released in 1972. It has got a diameter of 26mm (equals 11 1/2 lignes) and the oscillating weight adds another 3mm to its diameter, which in total is 29mm then.

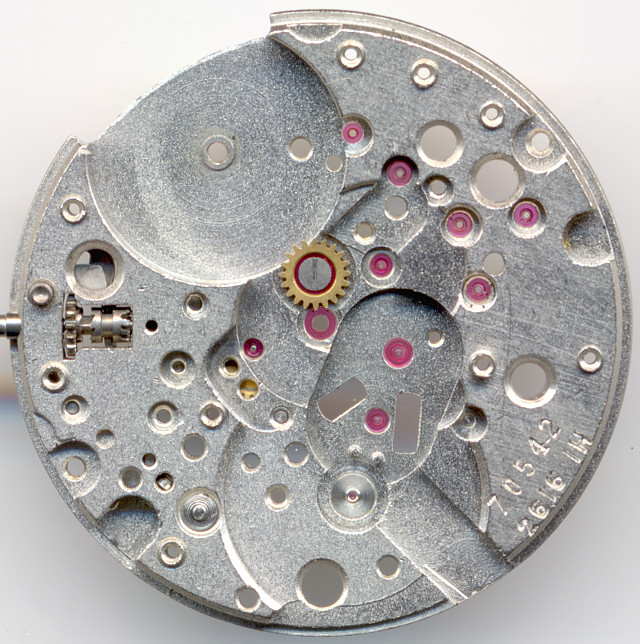

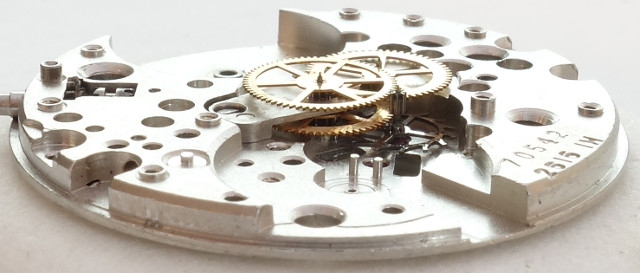

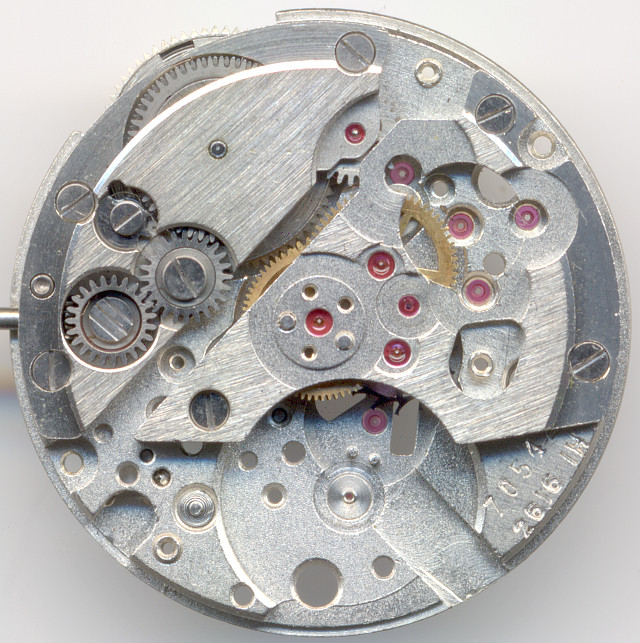

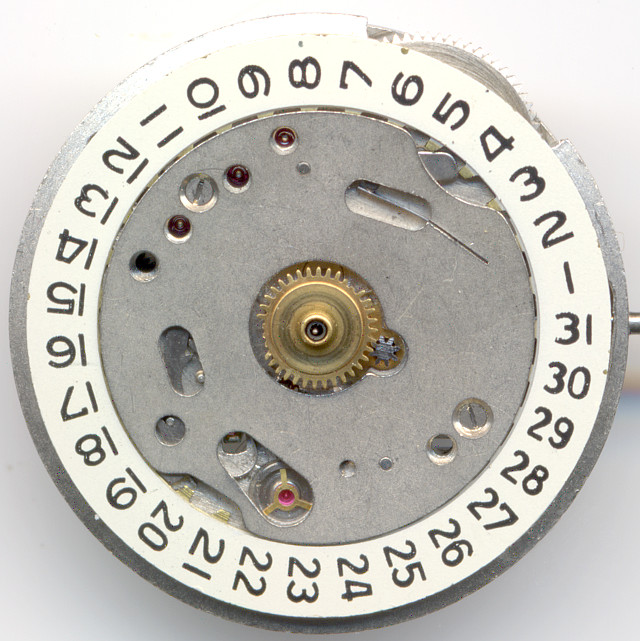

The base plate shows a very high number of jewelled bearings. Near the center, there’s a true oddity: Between the center minute wheel and the mainspring barrel, there’s a transmission wheel, which is screw- and ruby beared. It’s an indicator, that unlike most other movements, the mainspring barrel turns here counterclockwise (seen from the base plate).

The center minute wheel is beared under an own bridge.

With the exception of the additional transmission gear between mainspring barrel and center minute wheel, we have the classical gear train with third wheel, directly driven center second wheel and escape wheel. The rectangular cutouts next to the escape wheel teeth allow oling the pallets from the dial side. The escapement is a classical swiss pallet lever escapement.

The Poljot 2616.1H uses a three leg anular balance, which is beared in two inhouse shock protections, also with three legs. It beats slowly with 18000 A/h and can only be adjusted with the hairspring key.

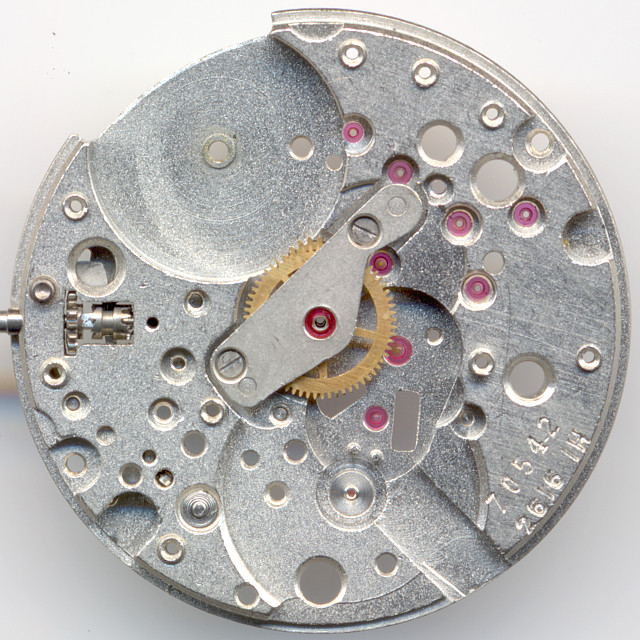

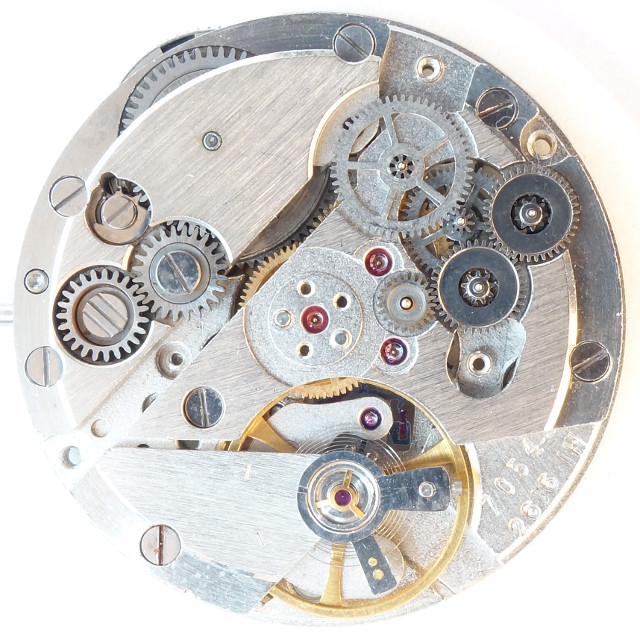

When both bridges are mounted, you can see, how many bearings are used for the selfwinding mechanism.

On this movement with its strictly geometrical cut bridges, there’s another transmission wheel between the crown wheel and the ratchet wheel. This is due to the fact, that the mainspring barrel turns in the unusual counterclockwise direction.

The selfwinding mechanism is directly integrated into the movement, which reduces the height of the movement.

The selfwinding gear train ends with a transmission wheel, which interferes with the ratchet wheel. Before this transmission wheel, there a two further transmission wheels, two connected exchange wheels and a first wheel, which connects with the oscillating weight. An impressive amount of gears!

Both exchange wheels are connected to each other an spring freely in one direction each. This allows the oscillating weight to wind the movement in both directions.

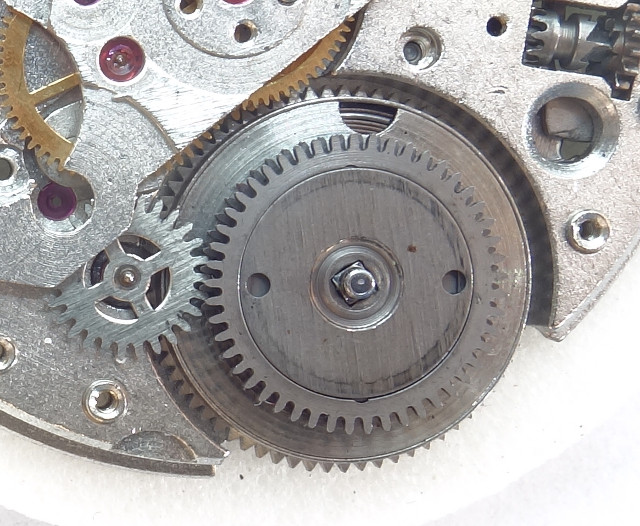

The ratchet wheel has got an interestion construction, which is not really new: It consists of two wheel, which are coupled with the inner plate, which itself is attached to the mainspring barrel and winds it. Both wheels turn freely in one direction and engage with the inner plate in the other direction.

This construction was invented some decades ago and ensures, that the selfwinding mechanism is decoupled when the movement is manually wound.

The half-circle oscillating weight is axle-beared and engages with the first transmission wheel of the selfwinding mechanism.

When the oscillating weight is not mounted, you can see the impressive glory of the many jewels.

On the dial side, there’s also one additional transmission wheel between the change wheel and the hands setting wheel of the keyless works, so on this movement, unlike most other movements, when you turn the crown clockwise, the time advances.

The hour wheel (which misses some teeth here) has got two gears, the larger one is driven from the change wheel and the smaller one drives the date indication mechanism.

Of course, a movement like Poljot 2616.1H cannot just use a simple date indication mechanism. It has to use a very elaborate one, with instant date change at midnight, realized with a clamping slide and a spring. Probably the tension of the spring was too strong for the teeth of the hour wheel.

The date can be corrected semi-fast by turning the hands back and forth.

In the lab

Timegrapher result

In the horizontal positions, it perfomed extraordinarily well, and the vertical positions are also not bad for a heavily used movement.| horizontal positions | |||

|---|---|---|---|

| dial up | +1 s/d | 311° | 0.1ms |

| dial down | +6 s/d | 292° | 0.0ms |

| vertical positions | |||

| crown right (12 up) | -11 s/d | 226° | 0.2ms |

| crown up (3 up) | -15 s/d | 196° | 0.3ms |

| crown left (6 up) | +20 s/d | 183° | 0.0ms |

| crown down (9 up) | -20 s/d | 215° | 0.2ms |

Technical data

| Manufacturer: | Poljot |

| Caliber: | 2616.1H |

| Size: | 11 1/2''' (measured: 26,0mm) |

| A/h: | 18000 |

| Number of jewels: | 30 |

| Escapement: | Pallet lever |

| Balance types: |

Glucydur anular balance |

| Shock protection(s): |

3 arms, russian |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 4 hole(s) |

| Features: |

|

| Production period: | 1972 - ???? |

| Inventory number: | 18012 |