Description

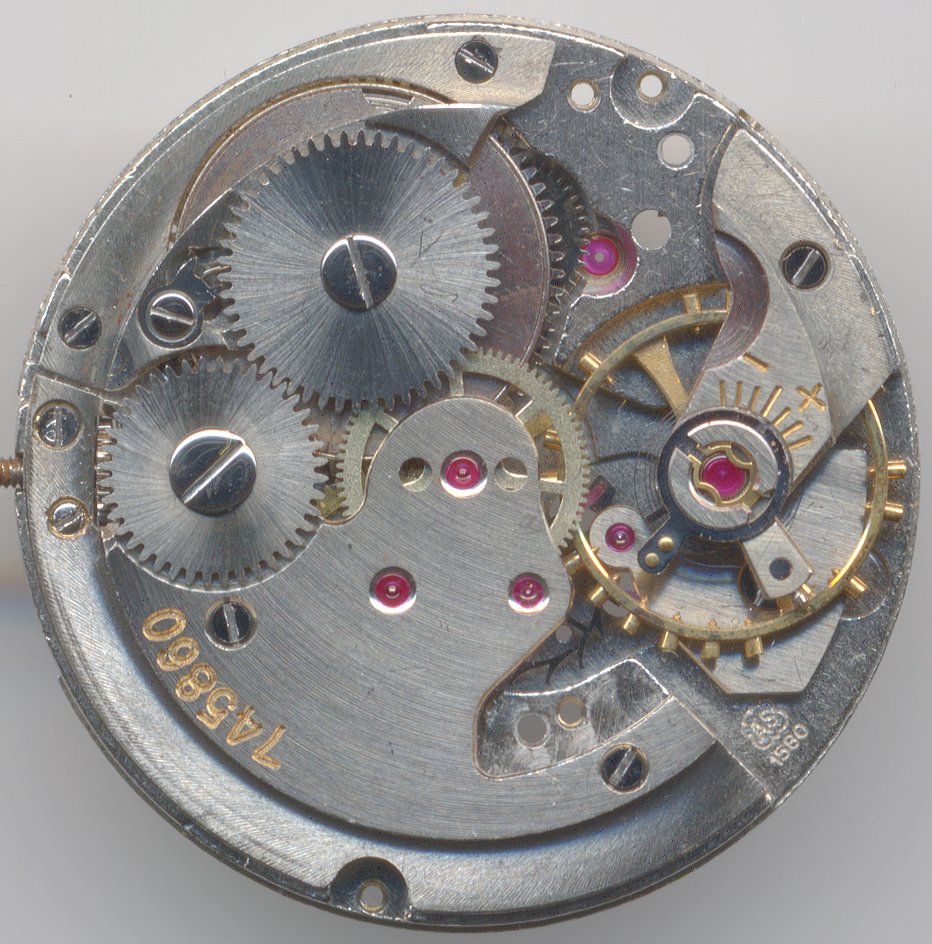

The AS 1580, called “Maximatic” debuted 1958. It had a selfwindig mechanism, which was partially integrated and wound in both directions. The “Maximatic” caliber was used in at least three families until it was surpassed by the series 1716. These three families were the 1580-series, the 1680-series and the 1700 series. The differences are small, hardly noticeable, and even the Flume Werksucher does not show them in detail.

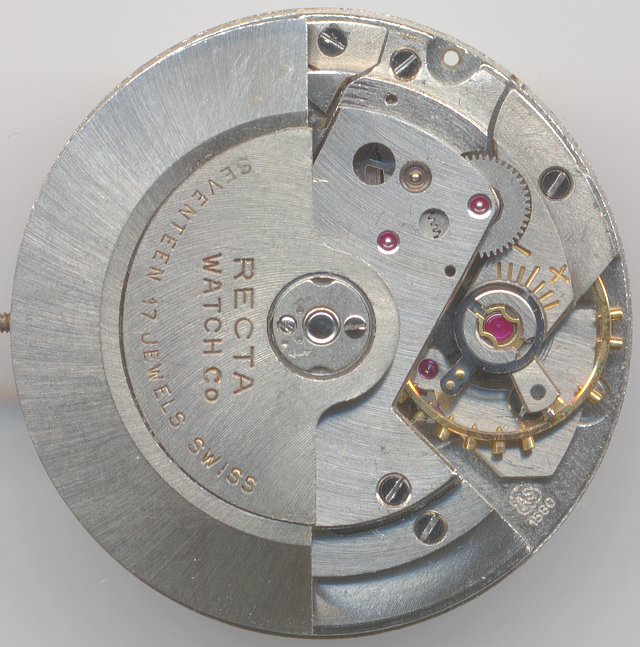

Video on YouTubeOn this movement, the oscillating weight is axle-beared.

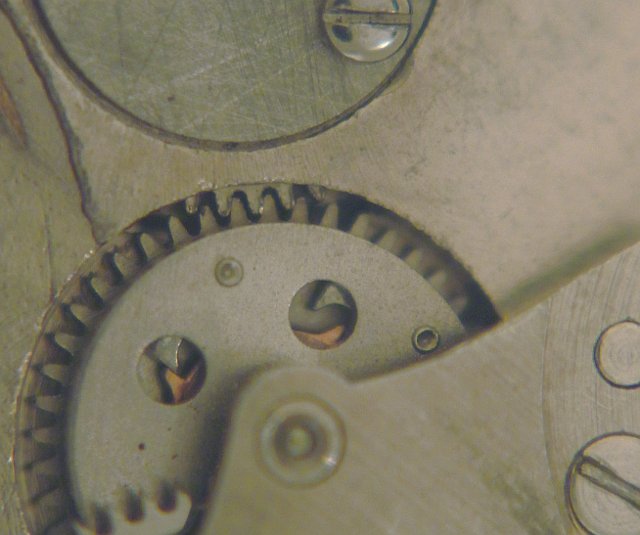

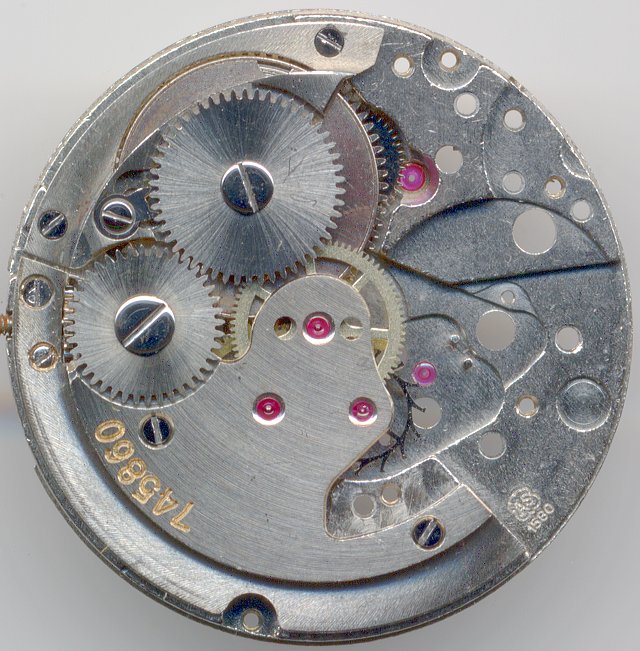

The oscillating weight with its outer teeth is located in a depthened part of the upper selfwinding plate.

With a locker and its screw, the oscillating weight can be released from the axle.

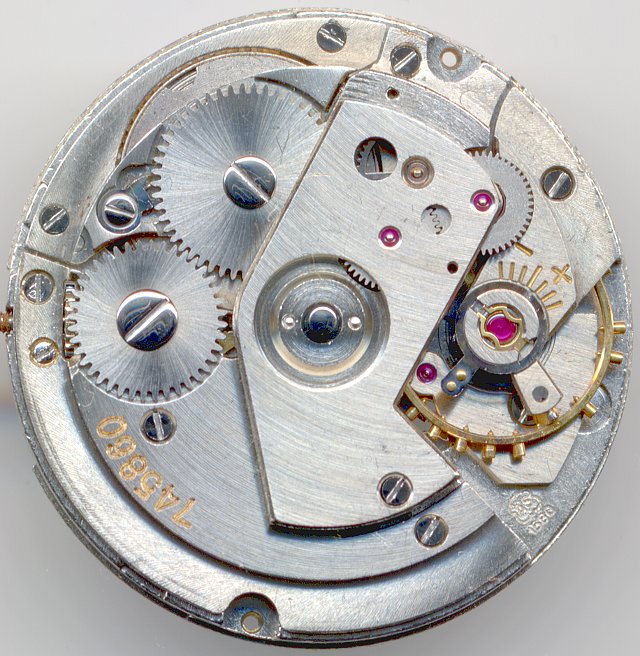

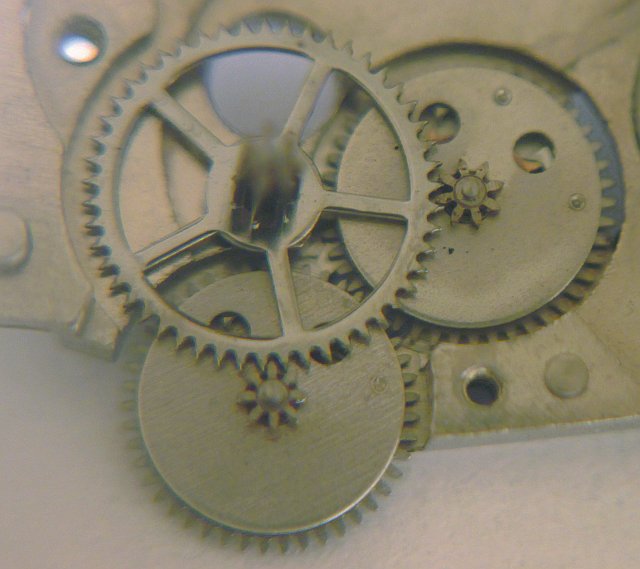

The selfwindig mechanism consists of three gears: A click wheel, which is driven by the oscillating weight, a further click wheel, which is driven by the first one and turns in the opposite direction, and a reduction wheel, which drives the winding mechanism on the main plate.

The oscillating weight turns the first click wheel in both directions.

The second click wheel is driven by the first one and so turns on the opposite direction.

The click changer achieves, that the pinion only turns in one direction and is released in the other direction. With that, it is guaranteed, that although both wheels turn in both directions, their pinions only turn in one single direction. And this is a requirement for a selfwinding mechanism, which winds in both directions with a very small dead angle.

The two click wheels are jewel-beared, but only on the movement side. The reduction wheel is beared in a hardened metal bearing - here’s indeed a difference to the other “Maximatic”-caliber families, on which this wheel is jewel-beared, too, and even has got a cap jewel.

The motion works of the AS 1580 are like on a standard handwound movement, which only has got a little free spare space, in which a selfwinding mechanism was integrated.

The golden toned Glucydur-screw balance beats slowly with 18000 A/h. In the specimen shown here, it is beared in two Incabloc shock protection bearings.

The blued Nivarox-I hairspring guarantees best precision. Its one end is fix connected to the balance cock (some movements of the other Maximatic caliber series already have got a moveable hairspring stud), its effective length can be adjusted on the hairspring key only. As you can see, the selfwinding mechanism requires some space, which would collide with a long regulator arm.

The construction of the movement works is pretty modern for 1958 as the center second is directly driven.

To save vertical space, the flat minute wheel is beared under an own cock. Even todays’ movements often use that kind of construction!

The mainspring barrel is beared under a very small bridge. On this, just on standard handwound movements, a click mechanism is used.

To release the selfwinding mechanism on handwinding the movement, a breguet coupling is used on the bottom of the mainspring barrel. The decoupling of the selfwinding mechanism reduces wear on its gears.

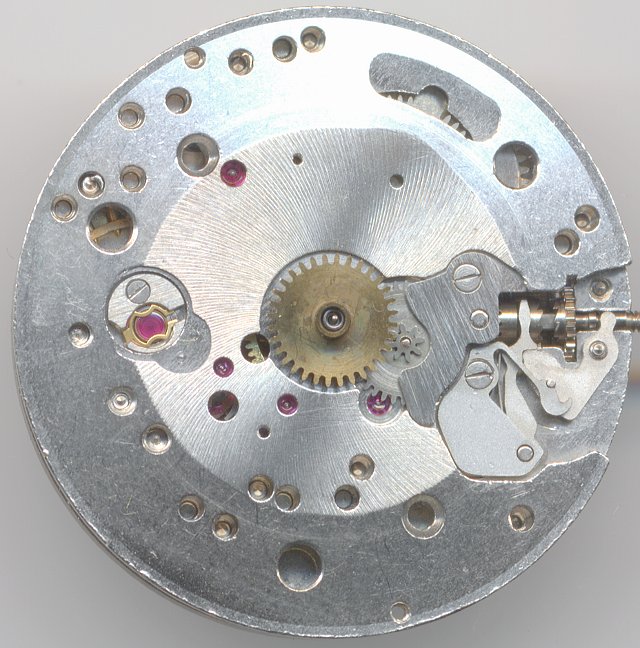

Below the mainspring barrel, you can see the second part of the breguet coupling. It is driven by the dial-side reduction wheel of the selfwindig mechanism. This wheel is turned by the selfwindig mechanism shown above.

As you can see, there’s still a lot of unused space on the main plate. The movement construction is a very efficient one.

On the dial side, you immideatly recognise the Incablock shock protection with its own plate. On other movements, there are different shock protection systems or even no shock protections at all.

Of course, such a fine movement has got a yoke winding mechanism. Here, the setting lever spring has got a very special shape (at position “4”).

In the lab

The movement came loose, only with a dial, into the lab. It was probably taken of a gold watch (whose case was melted, what a pity!). To ensure, that there's no dirt in the movement, it was completely disassembled, cleaned and oiled.

During the disassembly, a large water damage became visible. It could be removed more or less, but there's sure some invisible damage on the movement.

Timegrapher result

The results on the timegrapher are pretty poor, especially on such a fine movement (selfwindig and with Glucydur screw balance) from such a fine manufactory. It's likely, that the water damage above, and maybe also some shocks in the past and probably long revision periods harmed the movement and are responsible for the results. These are strongly depending on the position, but they are very constant!.

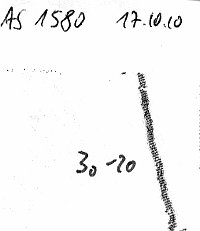

crown right (12 up)

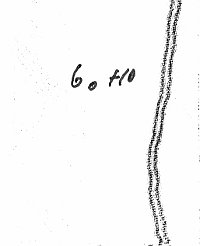

crown up (3 up)

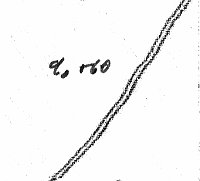

crown left (6 up)

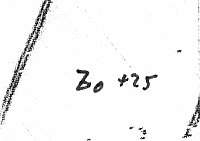

crown down (9 up)

dial up

dial down

| horizontal positions | |

|---|---|

| dial up | +25 s/d |

| dial down | +20 s/d |

| vertical positions | |

| crown right (12 up) | -5 s/d |

| crown up (3 up) | -20 s/d |

| crown left (6 up) | +10 s/d |

| crown down (9 up) | +60 s/d |

Technical data

| Manufacturer: | AS |

| Caliber: | 1580 |

| Size: | 11 1/2''' (measured: 25,6mm) |

| A/h: | 18000 |

| lift angle: | 52.23° |

| Number of jewels: | 17 |

| Escapement: | Pallet lever |

| Balance types: | Glucydur screw balance |

| Shock protection(s): | Incabloc |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | no |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 2 holes |

| Features: |

|

| Production period: | 1958 - 196? |

| References: | Flume: 1962 94 |