Description

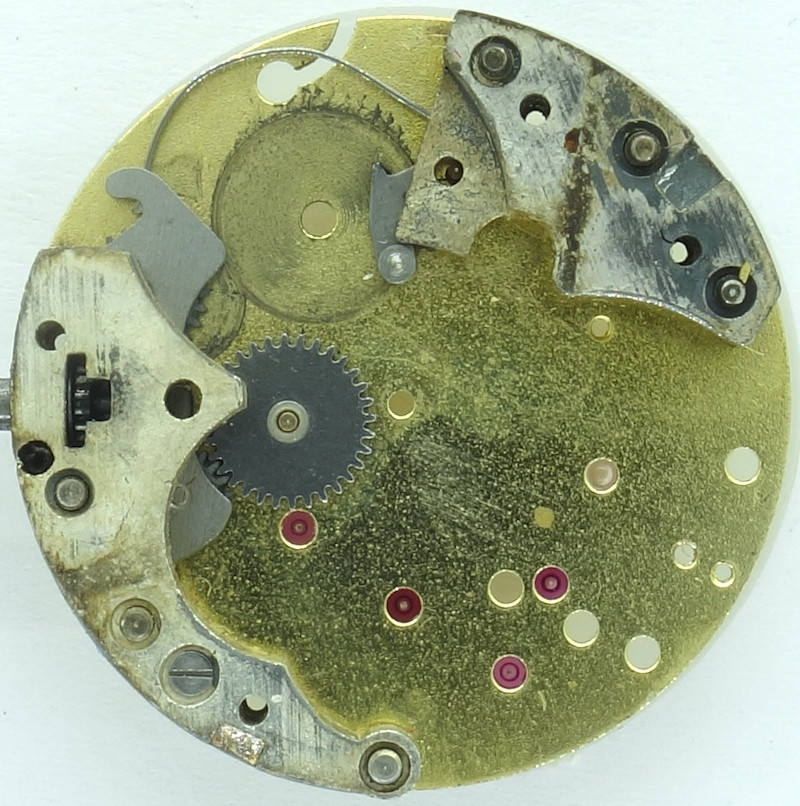

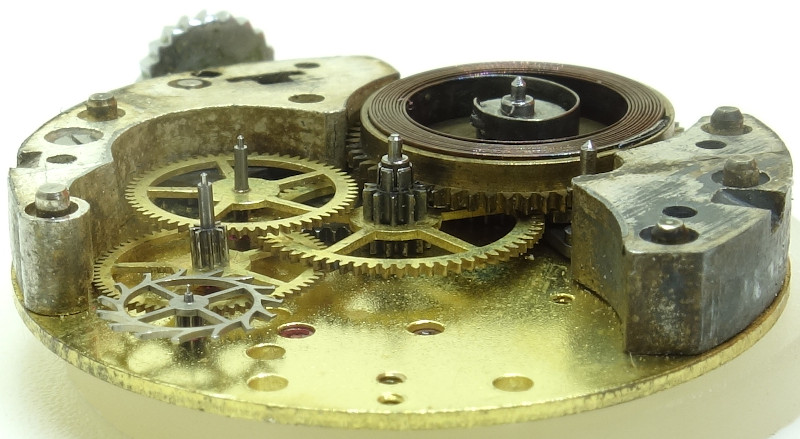

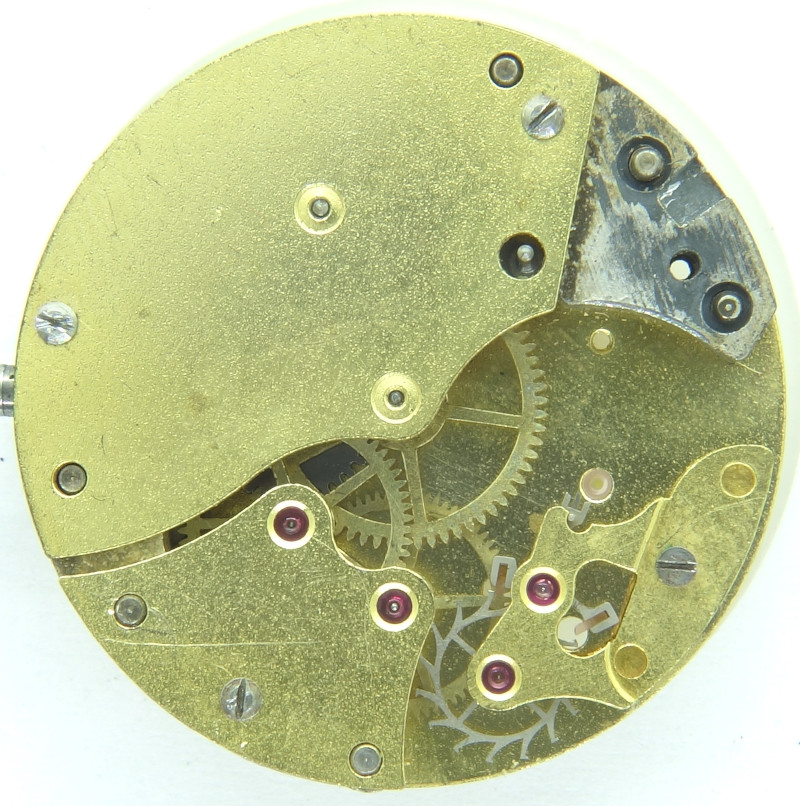

Probably for cost-saving reasons, Buser introduced for their pillar construction Buser 36 this odd construction, where the rocking bar winding system, the ratchet and the setting- and reverse wheel are located on the inner side of the base plate.

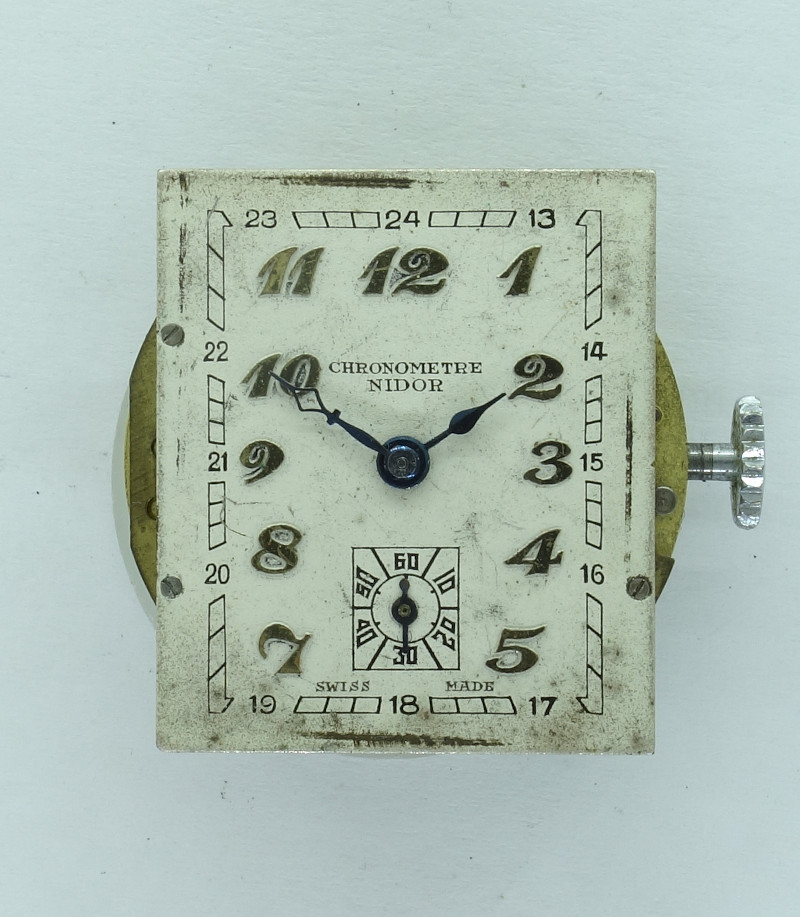

If it was properly executed, it might have worked well, but at least on the specimen in the archive, the accurancy of fit is so bad, that this 10 1/2 ligne movement is highly unrealiable.

On the positive side is, that all important bearings use rubies.

The execution of the ratchet, however, is so bad, that its long pin interfers with the minute wheel and even blocks it!

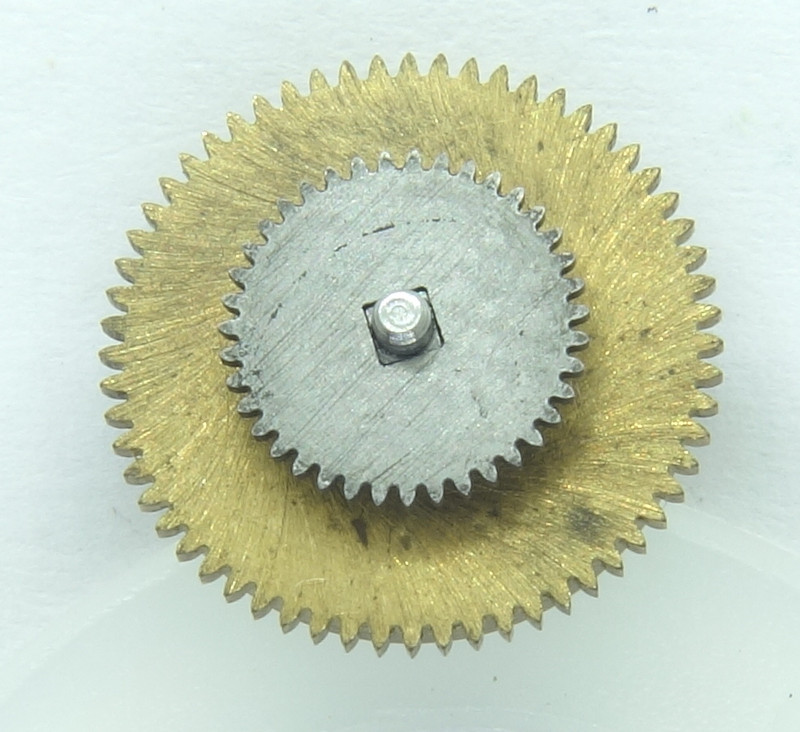

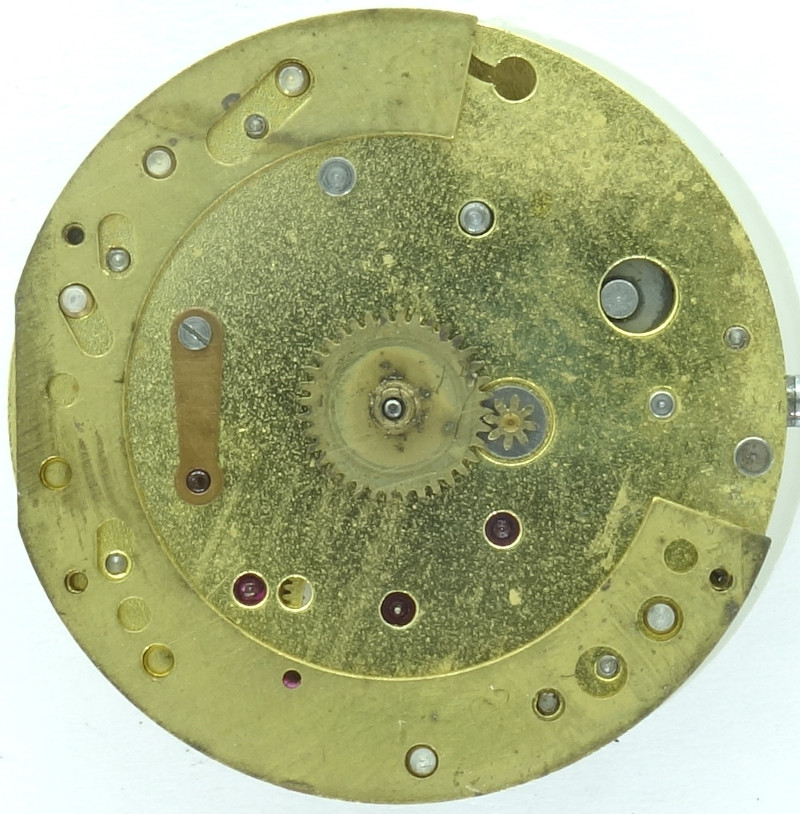

The mainspring barrel is open on its upper side and carries the ratchet wheel on its lower side.

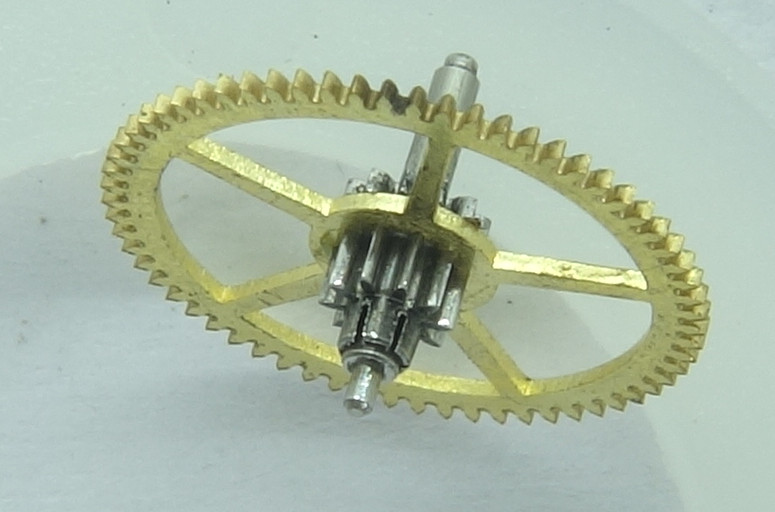

Since the hands settings is done on the movement side, the minute wheel carries a slipping clutch for its lower pinion and axle. The lower pinion engages with the setting wheel. The upper pinion is driven by the mainspring barrel.

Unfortunately, the minute wheel is beared warped between base plate and gear plate.

Except for the minute wheel, the gear train is the classical one with mainspring barrel, directly driven center minute wheel, third wheel, decentral seconds wheel at 6 o’clock and steel escape wheel.

The two-leg screw balance is beared on the dial side with an axially moveable cap jewel. This very simple shock protection can at least absorb slight shocks a little.

Of course, the Buser 36 beats with 18000 A/h. This rate can be adjusted with a long regulator arm.

Another oddity is, that third- and seconds wheel as well as escape wheel and lever are in pairs beared under their own cocks.

Since the cock for escape wheel and lever is very flat, the balance wheel can run above it and can be executed larger.

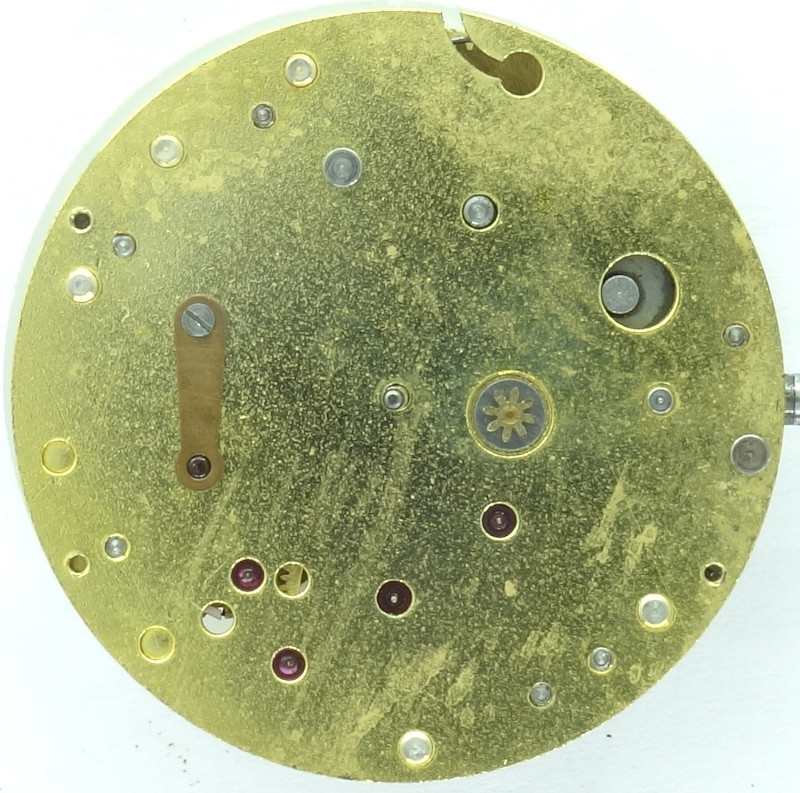

The dial side makes a really strange appearence, because you see neither the winding and hands setting mechanism nor the ratchet.

Only the reverser wheel at 3 o’clock indicates, that there might come more.

Since the base plate is completely flat on the dial side, a three-quarter spacer ring is required to give the reverser and hour wheel enough space, so that they don’t grind on the dial.

Additionally noteable is the axially spring-loaded cap jewel at 9 o’clock, an early and very simple kind of shock protection. Unfortunately, it is not really service-friendly.

Technical data

| Manufacturer: | Buser |

| Caliber: | 36 |

| Size: | 10 1/2''' (measured: 23,65mm) |

| A/h: | 18000 |

| lift angle: | 49° |

| Number of jewels: | 15 |

| Escapement: | Pallet lever |

| Balance types: | monometallic screw balance (two legs) |

| Shock protection(s): | Special |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | no |

| Adjust mechanism: | Long regulator arm |

| Construction: |

|

| Construction type: | pillar construction |

| Winding mechanism: | rocking bar winding system |

| Setting lever spring: | 1 hole |

| Features: |

|

| References: | Ebauches: 1949 II 36 Feilner: 25 1126 Flume: 1942 13 |

| Inventory number: | 22046 |