Description

As so often with chinese multifunction movements, this 10 1/2 ligne selfwinding movement could not be identified, too. It was made probably around the late 1990s or early 2000s.

There’s only a single image on the net, a caliber denoted as “JHB17” which seems to match at least from the hands order on the dial side, but there are no more details, too, and so it has to remain anonymous.

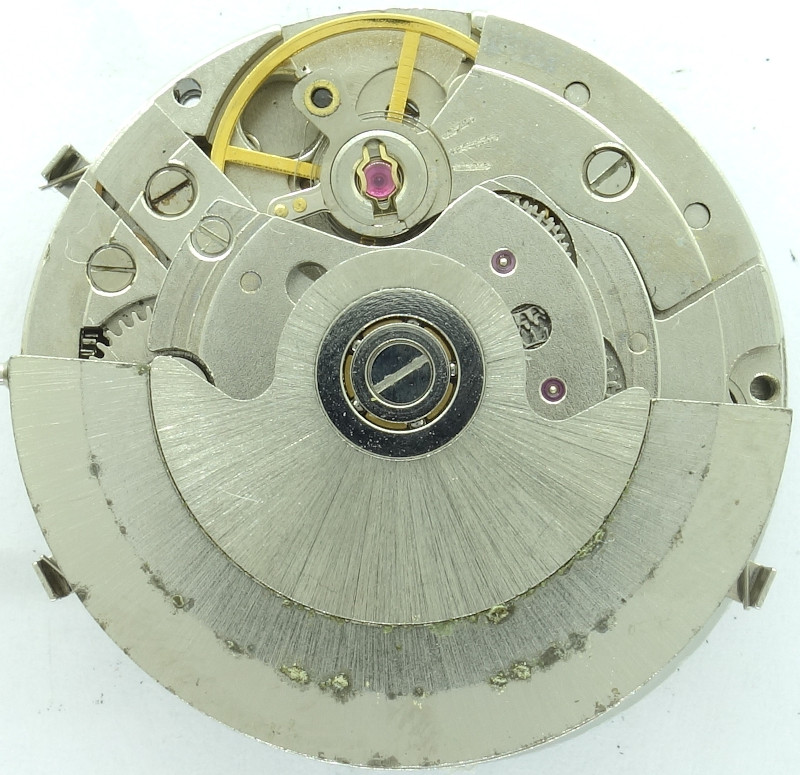

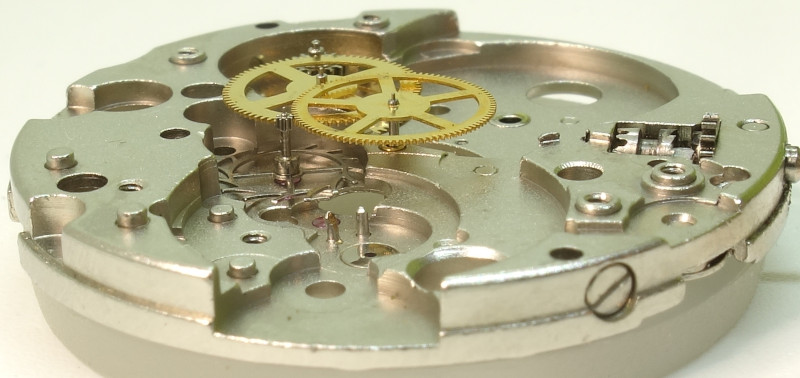

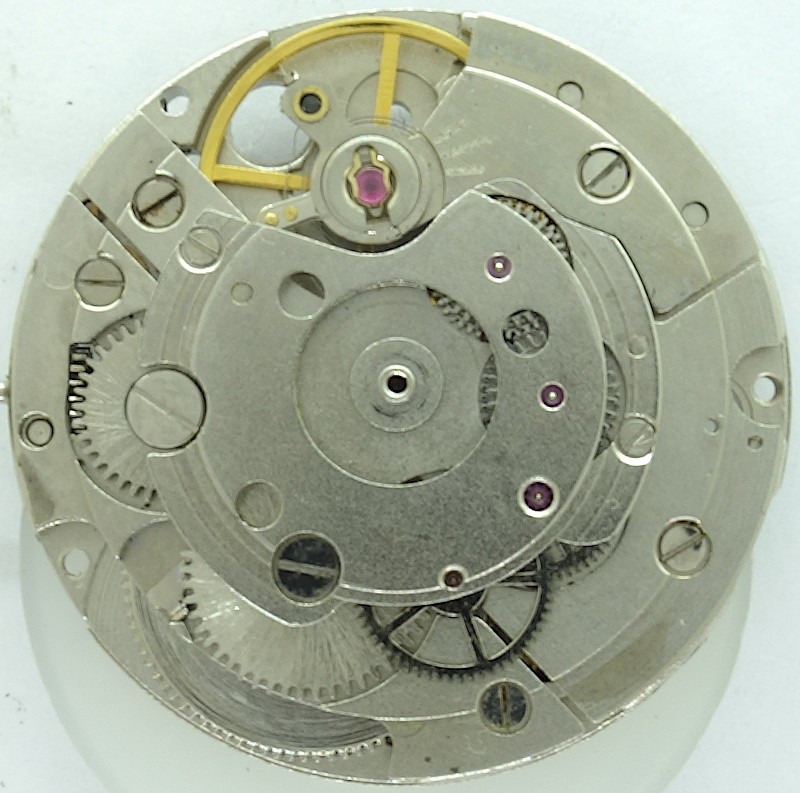

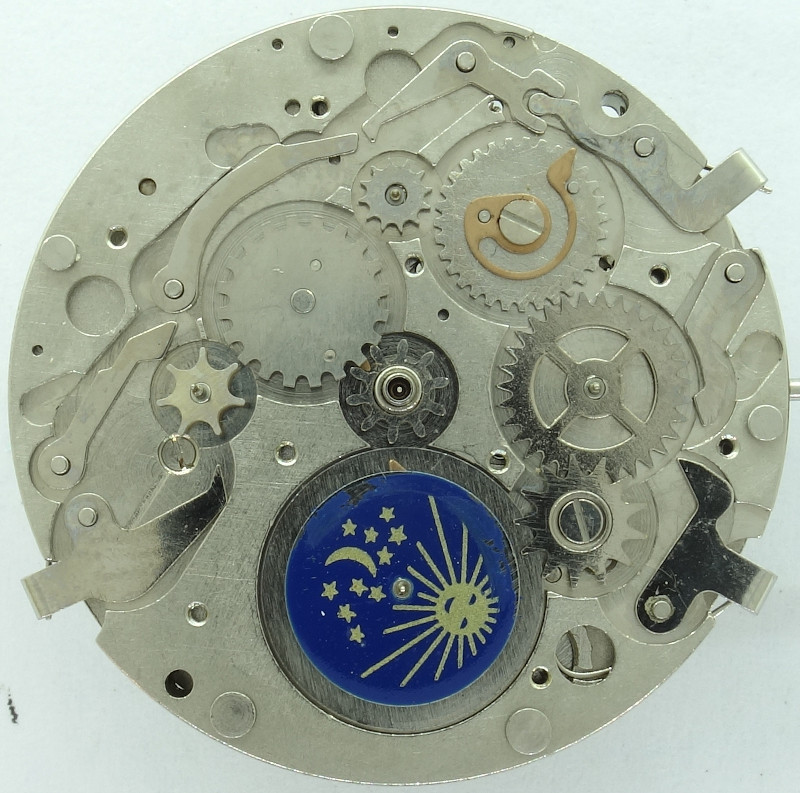

From a distance, the movement side with its oscillating weight reminds a bit of an ETA 2824, but only at a first glance.

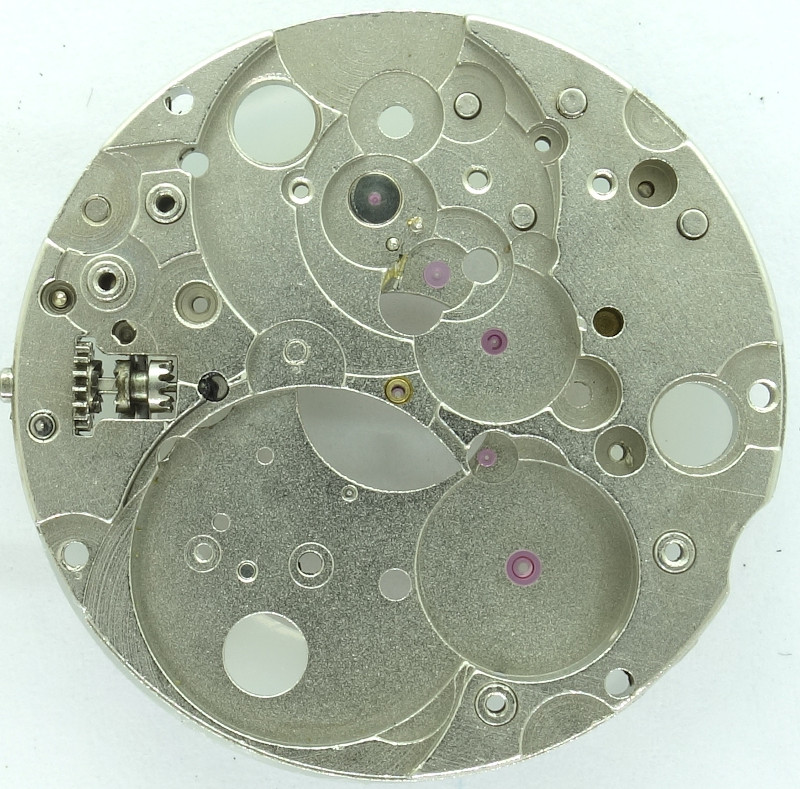

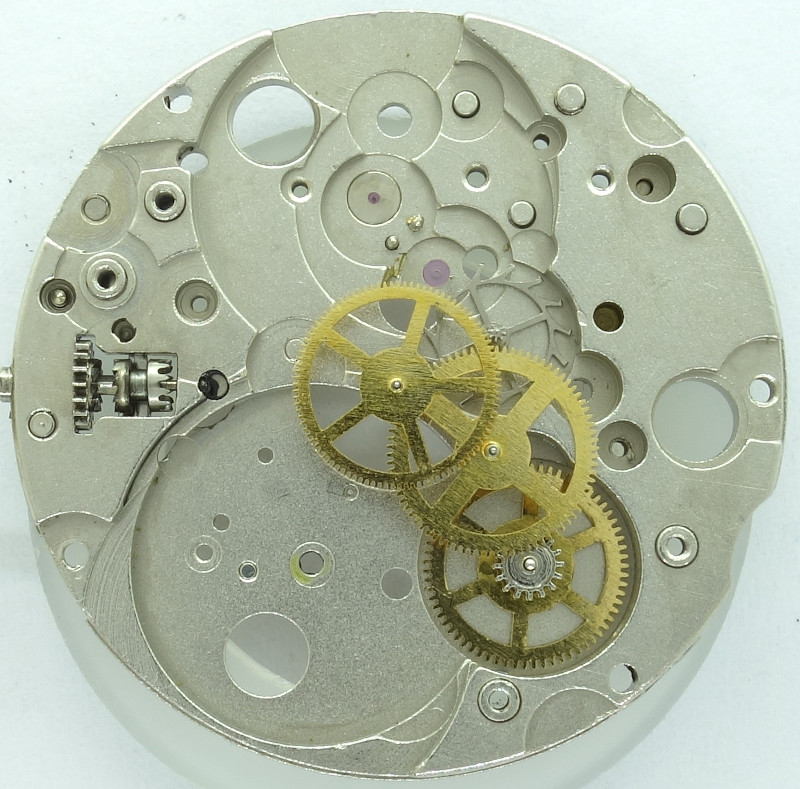

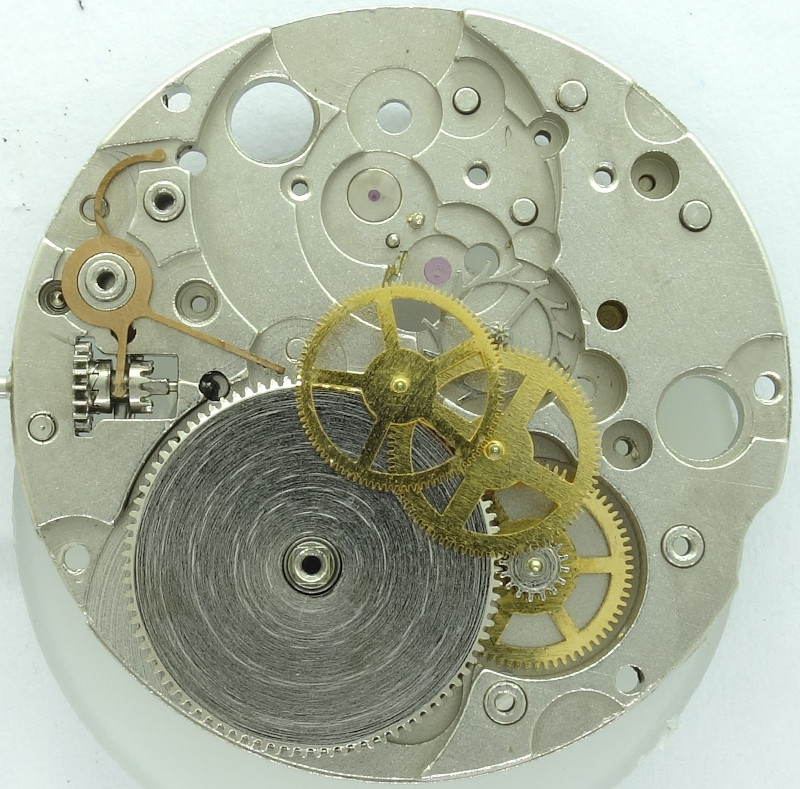

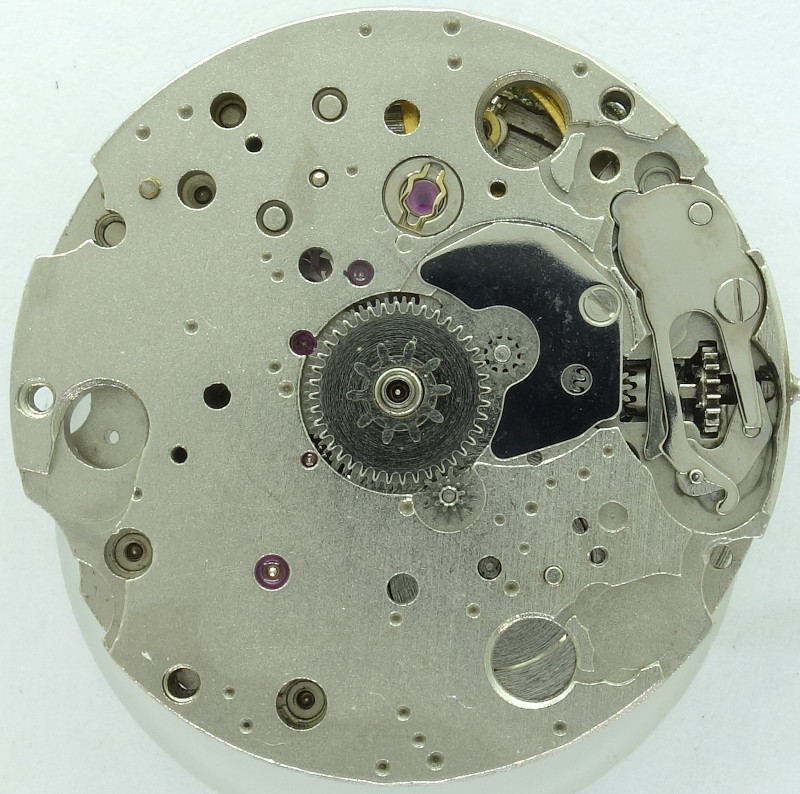

The base plate also reminds a bit of ETA movements due its gear train, and also here, all important bearings contain rubies.

The gear train is made like on ETA movements with an indirectly dial-side driven hand works. For that, the mainspring barrel drives the massive second wheel, followed by the third wheel, whose pinion also drives the hand works on the dia side.

Finally, we have the directly driven center seconds wheel and the steel escape wheel.

A decade-long proven construction principle, which is valid until today.

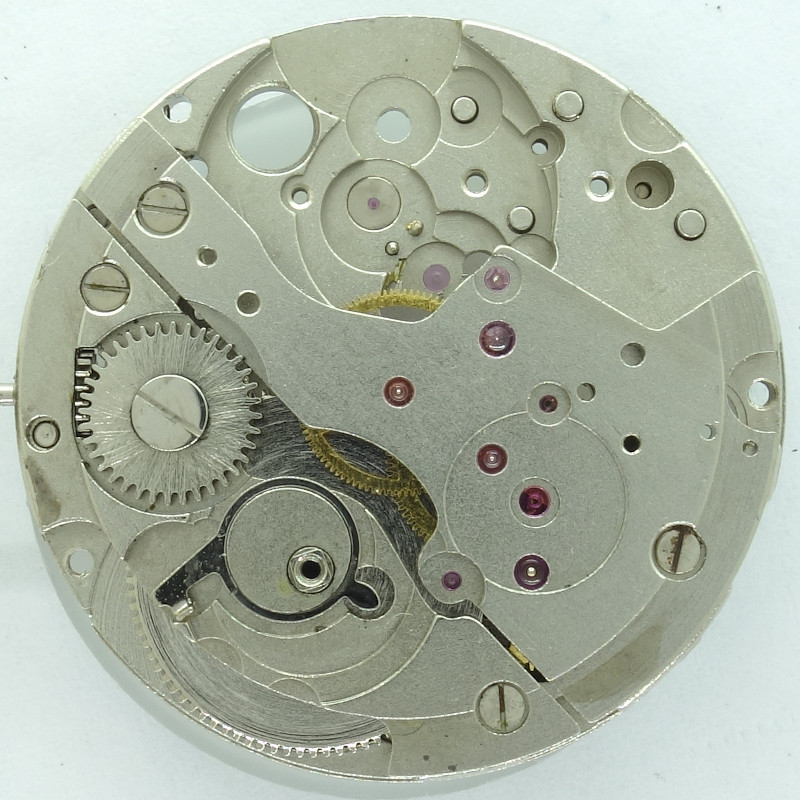

As escapement, a swiss pallet lever escapement is used, controlled by a four leg anular balance. It beats slowly with 21600 A/h and it beared in two chinese shock protections, which remind of Incabloc bearings, but differ in details like a slightly changed geometry and a thicker lyra spring.

This movement can be regulated at the hairspring key only, but has got a hacking mechanism, consisting of a spring-loaded lever, which has to be mounted at the excact point of time.

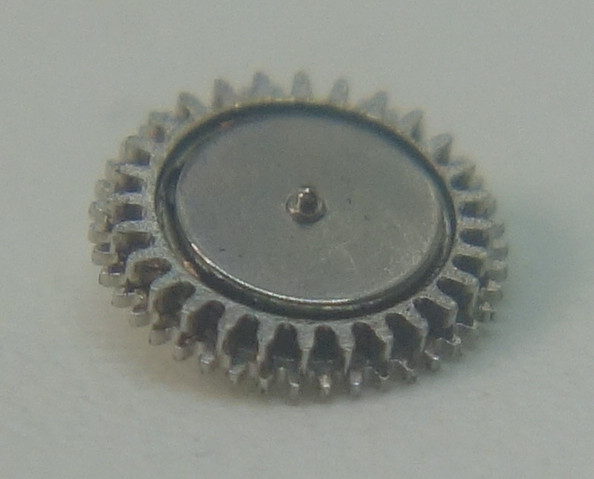

The ratches is a simple but efficient construction, made of one single spring-loaded lever, which is located below the ratchet wheel and which engages into it.

When the selfwinding mechanism is yet missing, there are no resemblances to the ETA 2824, but rather to different chinese movements with a similar number of functions.

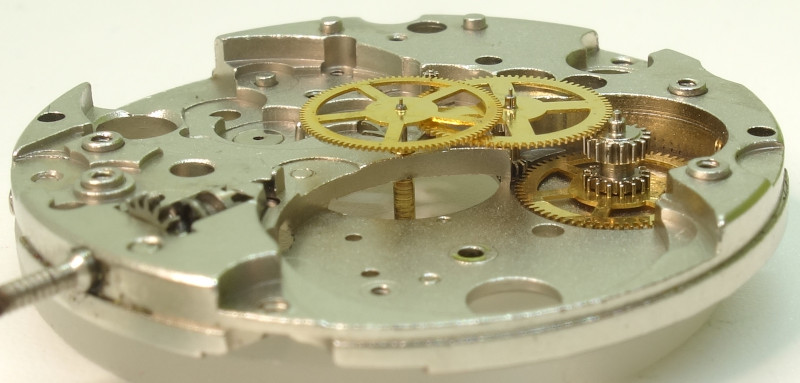

The selfwinding gear train consists of two roll changers of “Gyrotron” type according to Girard-Perregaux, where the lower gears engage into each other and the upper ones engage with the oscillating weight. Five rolls, here made of steel, ensure, that with the upper wheel of a changer turns in one direction, the lower wheel is driven, and when the upper wheel turns into the other direction, there’s no engagemenet with the lower wheel.

After the two roll changer wheels, there are two reduction gears, where the last one engages with the ratchet wheel and drives it always in the same direction, regardless of the rotating direction of the oscillating weight.

The rolls, rather metal discs here, are difficult to see, even in the detail view.

Visually, the selfwinding mechanism reminds a bit of those of ETA movements, and …

… the ball beared oscillating weight is 1:1 copy of those of ETA selfwinding movements.

At 8 o’clock, you can see the pinion of the third wheel, which drives the minute wheel on the dial side. This minute wheel has got a friction-clutch-mounted cannon pinion.

Additionally, you can spot the yoke winding system on the right.

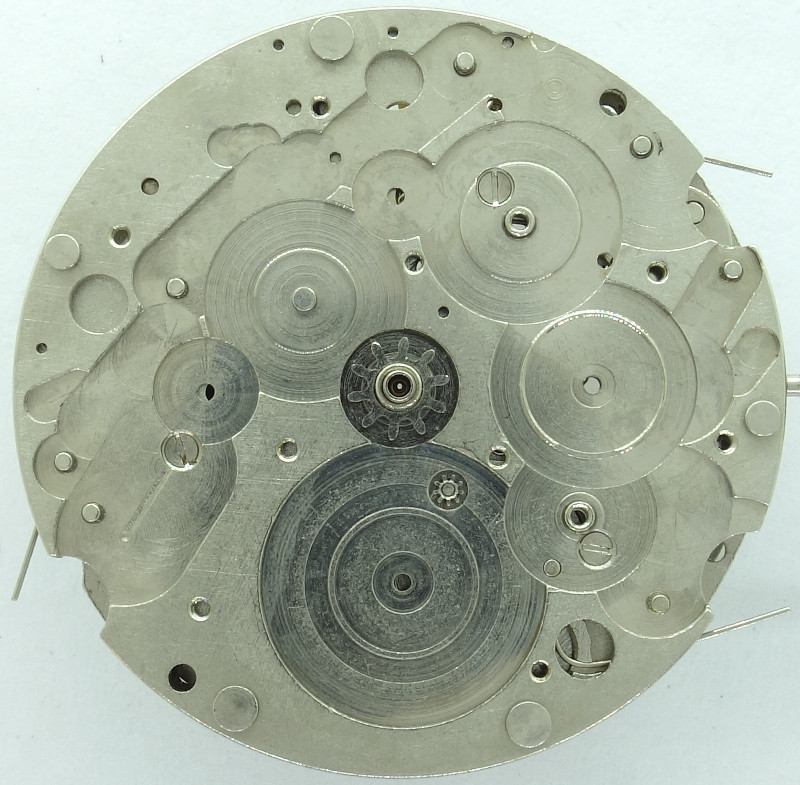

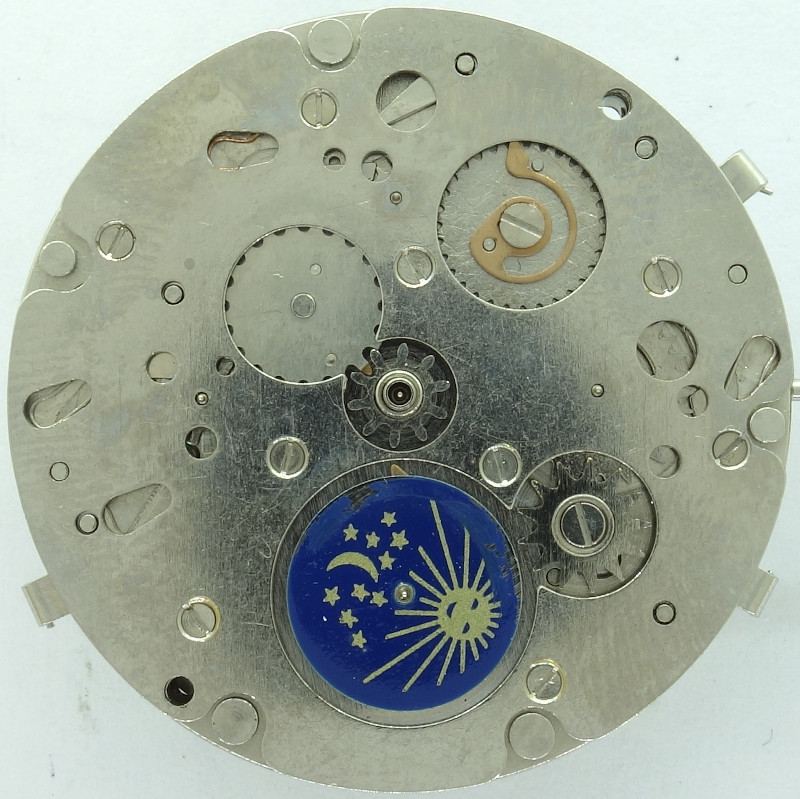

As usual, the canon pinion drives a changer wheel, which is followed by the hour wheel.

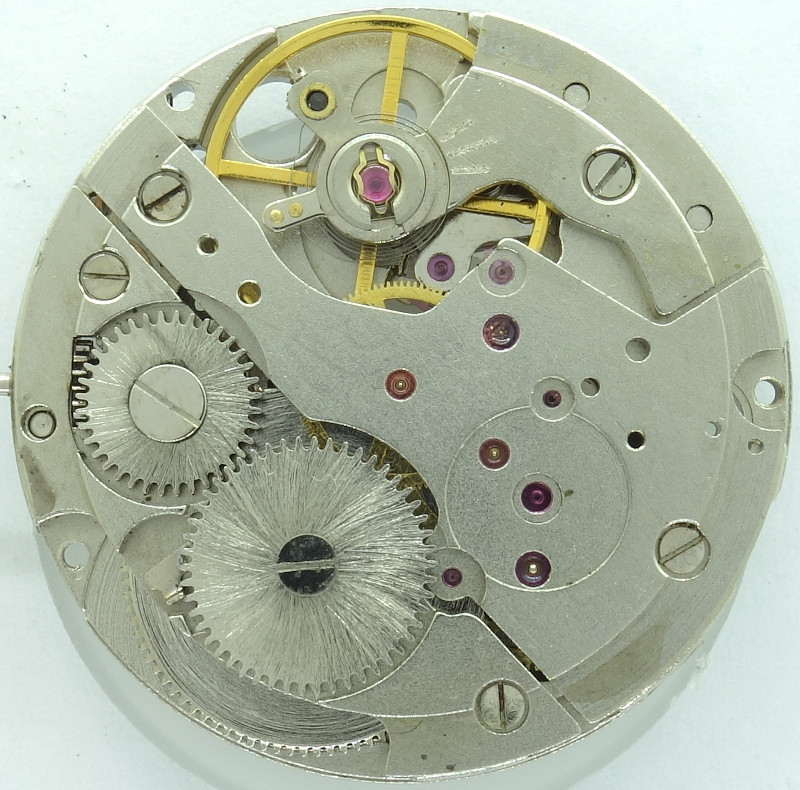

For the calendar mechanism, the hour wheel contains an additionally 10 teeth gear on top, and at position 5 o’clock, there’s the tiny driving wheel for the 24hr disc.

At positions 1, 5 and 9 o’clock, you see the recesses for the springs, which are required for the calendar setting correctors.

The complete calendar mechanism is mounted on an own plate, which is mounted with screws on the dial plate.

It is driven by the central hour wheel and additionally from the tiny driving wheel at 5:30.

This decoupling makes a service easier, because the simultaneous switch at midnight of date and weekday can be adjusted with the help of the day/night disc.

The tiny driving wheel at 5:30 drives the day/night indication at 6 o’clock. A pin is responsible to advance the date pointer at 3 o’clock, and this day indication drives a switching wheel at 1:30 with a moveable pin, which advances the month pointer at position 12 o’clock every 31 days. For months with less than 31 days, a manual correction is required.

The hour wheel drives the weekday pointer at 9 o’clock with the help of an intermediate switching wheel, which at midnight avances the seven-star weekday wheel, which carries the weekday indication hand.

With the help of correcting levers, the three indications, weekday, month and date can be advanced individually. This must not happen during the regular switching times (roughly between 8pm and 4pm), because only the switching wheel for the month correction has got a moveable switching pinger, all others are fixed and would be bent then.

Since all the required levers tend to fly away easily, the calendar mechanism is covered with a plate.

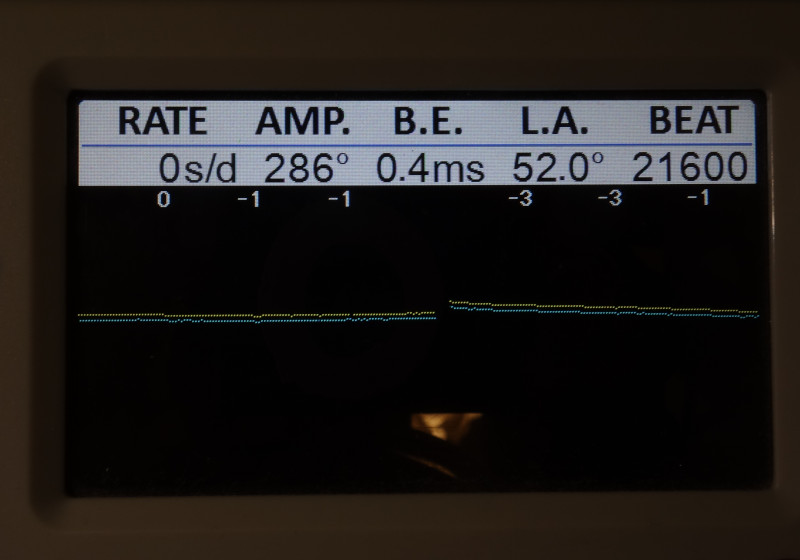

A big suprise regarding the crude execution of the movement are the very good timegrapher results, which were not expected at all here.

In the lab

Timegrapher result

The timegrapher results of this chinese movement are really impressive. Except one single anomaly, all rates are within the chronometer specification and even the power reserve of more than two days is remarkable:| horizontal positions | |||

|---|---|---|---|

| dial up | +-0 s/d | 280° | 0.1ms |

| dial down | -2 s/d | 277° | 0.3ms |

| vertical positions | |||

| crown right (12 up) | +-0 s/d | 241° | 0.5ms |

| crown up (3 up) | -10 s/d | 243° | 0.8ms |

| crown left (6 up) | -6 s/d | 227° | 0.7ms |

| crown down (9 up) | +-0 s/d | 233° | 0.7ms |

Technical data

| Manufacturer: | China |

| Caliber: | ? 2 |

| Size: | 11 1/2''' (measured: 25,6mm) |

| A/h: | 21600 |

| Number of jewels: | 23 |

| Escapement: | Pallet lever |

| Balance types: | monometallic anular balance (four legs) |

| Shock protection(s): | China (different types) |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 2 holes |

| Features: |

|

| Inventory number: | 22056 |