Description

In the early 1950ies, DuRoWe launched their very successful “Duromat” movement series, consisting of selfwinding movement for gents watches, which was continuously improved and led to many versions of “Duromat” movements.

Around 1960, the long-awaited “Duromat” for tiny ladies’ watches was launched, a truely unique selfwinding movement with a diameter of only 16.2 mm or 7 1/4 lignes. That’s a bit smaller than a european 1ct coin.

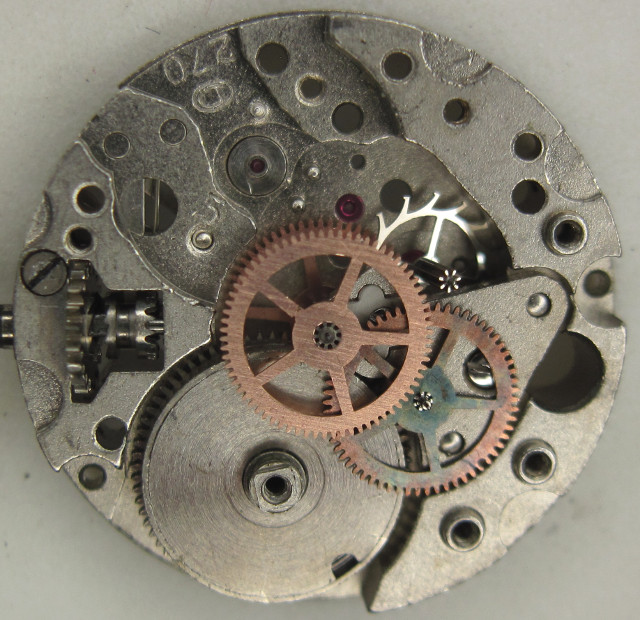

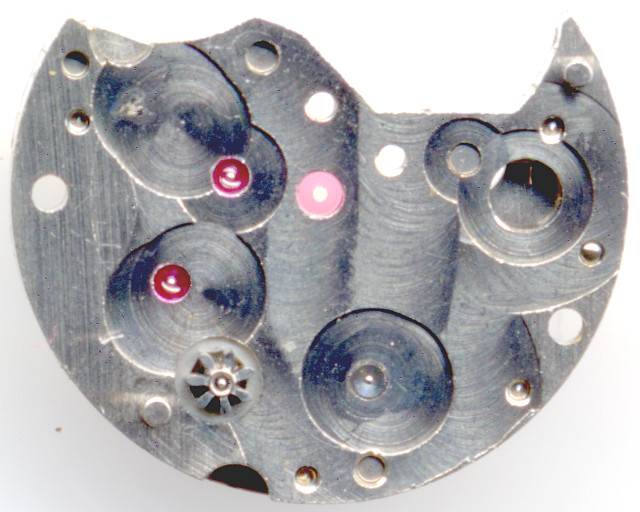

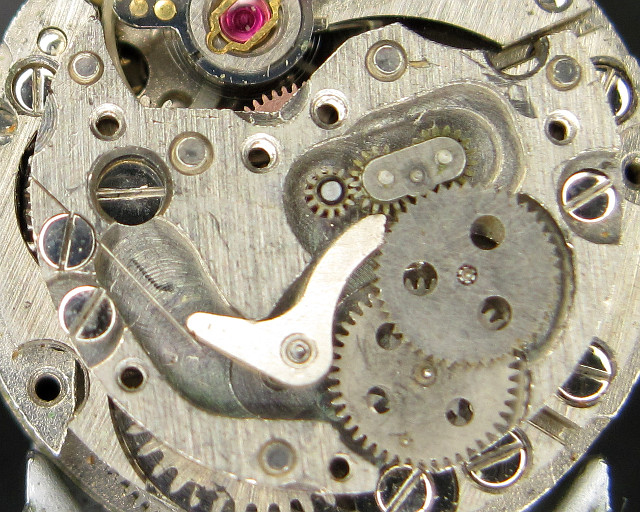

The base plate alone shows, how few space was available, but at that time, tiny ladies’ watches were up-to-date. To construct a selfwinding movement with only 16.2mm diameter was a real masterpiece, even when the movement had to build pretty high.

The gear train is typical for the 1950ies, it has got a directly driven center minute wheel as well a a directly driven center second wheel.

The screw balance in beared in two inhouse Duroswing shock protections and beats contemporarily slow with 18000 A/h. A faster beat rate is not possible with that small diameter of the movement.

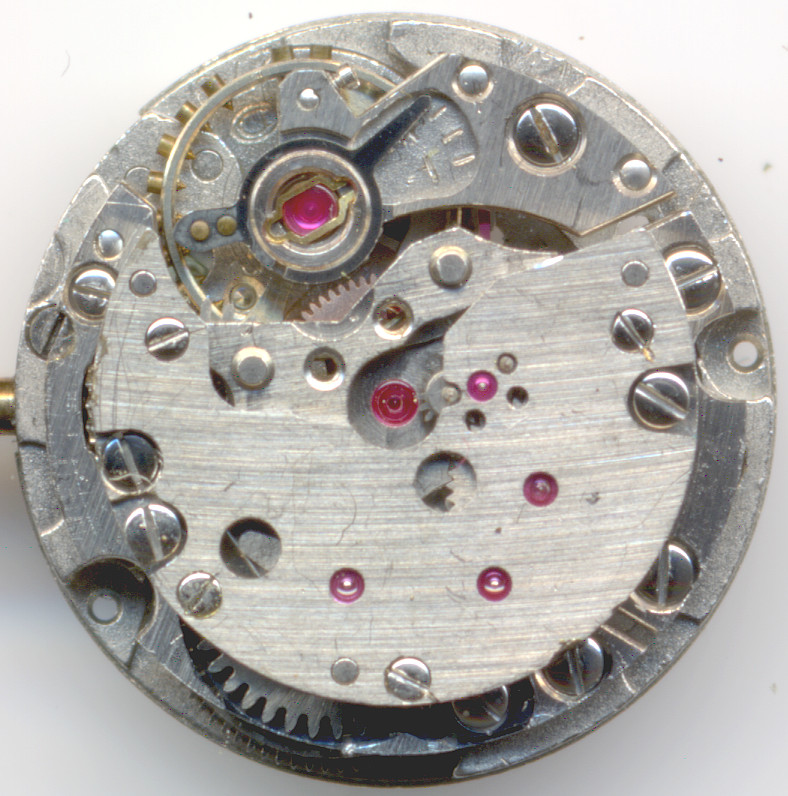

The selfwinding module is mounted with only two screws. It connects with the ratchet wheel. The base movement without the selfwindig module is nothing but a DuRoWe 260.

The selfwinding mechanism consists of the DuRoWe-typical rocking bar changer with two step gear train and a ratchet with ruby-beared click.

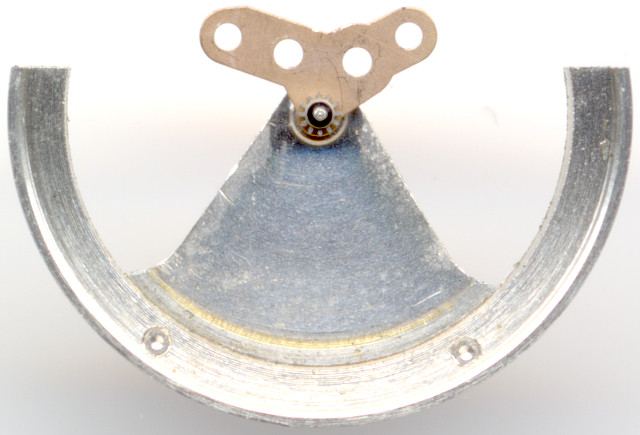

The bearing axis is part of the quite filigree oscillating weight.

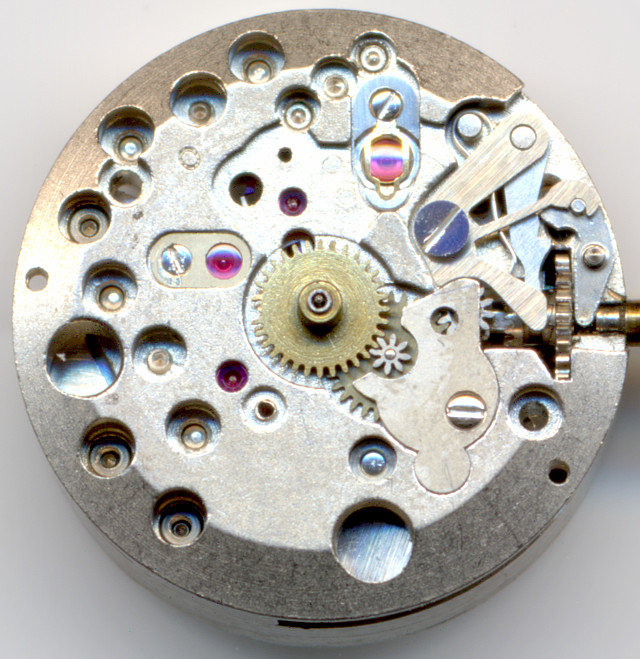

The top of the selfwinding module reveals its construction: The oscillating weight connects with the ruby-beared rocking bar changer (at 3 o’clock), the two reduction wheels are following, with the second one (at 5:30) connecting into the ratchet wheel. The ruby bearing at 6:30 belongs to the ratchet, which prevents unloading the mainspring barrel:

This construction is genious, especially, when you take into account, that the whole movement has got a little smaller diameter than an 1ct (Euro) coin. The drawback is, that it is not really service-friendly. The biggest problem is the small and fragile axle for the oscillating weight, which breaks on harder shocks. And the ratchet, which brakes the first reduction wheel adds some wear to it, since metal grinds on metal.

On manual wind, the selfwinding gear train is detached, so that even daily manual wind does not harm the movement. This function is implemented by the second reduction wheel and its two-ratchet clutch coupling. If the drive is rotated in a clockwise direction (in the top view on the underside), it rotates freely, so the selfwinding gear train is disengaged. On the other hand, when the wheel is turned clockwise, the right pawl engages the toothing and the drive is engaged. This is the case when the oscillating weight winds the movement.

On the dial side, you see the yoke winding system with its setting lever spring and the separated coverin of the changing and time setting wheel.

The escapement wheel (at 9:30) has got cap jewels on both bearings.

In the lab

Timegrapher result

The values show the performance of this movement in unserviced condition, after many years of use and probably even longer storage time:The rates differ a lot, additionally, the amplitide is pretty low except on the position “dial on top”. This is an indicator, that this specimen is due for a service. Nevertheless, the rates will more or less neutralize each other on daily wear.

| horizontal positions | |||

|---|---|---|---|

| dial up | +45 s/d | 254° | 1.1ms |

| dial down | 0 s/d | 160° | 0.9ms |

| vertical positions | |||

| crown right (12 up) | +90 s/d | 140° | 0.6ms |

| crown up (3 up) | +30 s/d | 143° | 0.9ms |

| crown left (6 up) | -64 s/d | 143° | 1.2ms |

| crown down (9 up) | +15 s/d | 143° | 0.9ms |

Technical data

| Manufacturer: | DuRoWe |

| Caliber: | 270 |

| Size: | 7 1/4''' (measured: 16,2mm) |

| A/h: | 18000 |

| lift angle: | 62° |

| Number of jewels: | 25 |

| Escapement: | Pallet lever |

| Balance types: | Nickel screw balance |

| Shock protection(s): | Duro-Swing |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | no |

| Adjust mechanism: | Long regulator arm |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 2 holes |

| Features: |

|

| References: | Flume: 1962 70 |

| Mentioning in literature (years): | 1960 |

| Inventory number: | 17003 |