Description

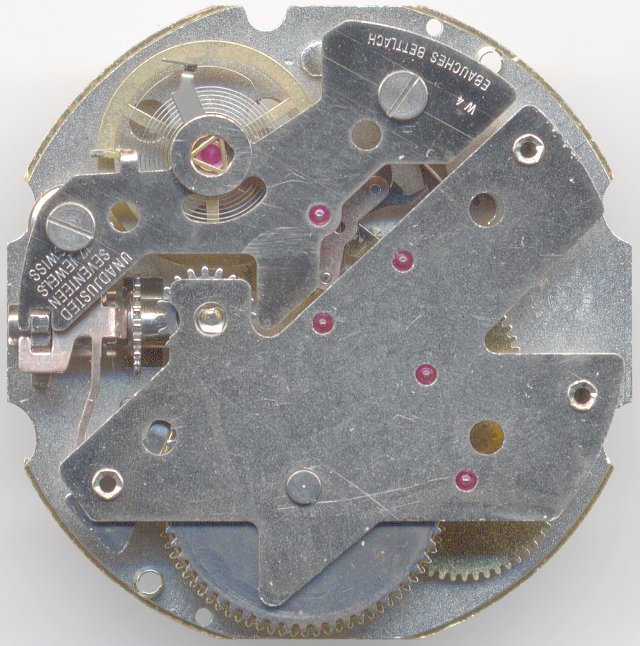

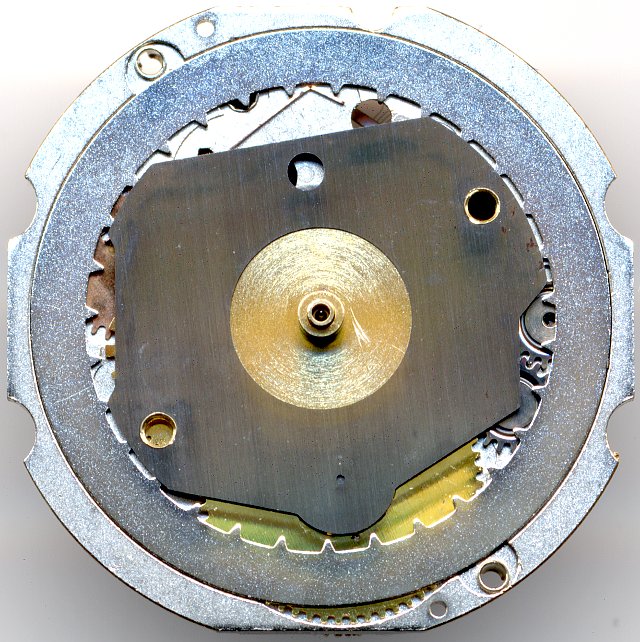

The mid-seventies movement EB 8503, here in the 1976 version, is a very idiosyncratic pin lever movement, which was constructed completely due to rational and cost-efficient production.

Although it is visually not much inspiring and due to its one-way construction with riveted plates it reminds strongly of a Timex movement, there are noteable differences to these movements. But one similarity share both - the movements are disposable and cannot be repaired on errors. And the EB 8503 came up just at the time, when Timex watches were most popular in Europe and could be found even in supermarkets and hence on almost every wrist.

The bridges of the EB 8503-76 are made of die-cutted metal sheets (a method which was even patended), but at least they contain ruby bearings for all gears.

The crown wheel has got a special kind of bearing: It is mounted loosely, so that it drives the mainspring barrel in one direction and in the other direction, it just slips away and turns freely. A simple but efficient construction.

The regulation works with its massive (means here “not open worked”) gears is constructed in a conventional way: A very flat ring balance, which is even beared in two Novodiac shock protections, beats with 21600 A/h. Its hairspring is fix soldered(!) to the balance bridge and can be regulated in its effective length with a simple u-shaped wire, which works as hairspring key. The escapement system is a pin lever. It controls a movement with directly driven center second and an indirectly driven minute hand on the dial side - a modern construction.

Video on YouTubeOne of the special constructions of this movement is the winding system: Unlike on normal movements, there’s no yoke winding system and no rocking bar system, too, but the crown wheel is plugged into a connector wheel, which either drives the dial setting wheel (when pulled out) or the winding wheel (when pushed in). In the video, you can see this minimalistic construction working.

The date setting mechanism is invisible, since the top plate is riveted and cannot be removed. The driving mechanism for the minute wheel is invisible, too.

In the lab

The movement worked at first pretty well, after it was cleaned and olied, but after a few days, it stopped working again.

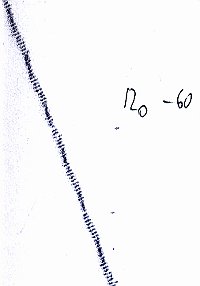

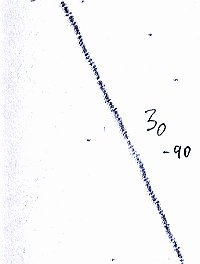

Timegrapher result

As expected, the timegrapher printings show very consistent lines, which prove the minimal wear of this movement. Especially the very small beat error shows, how effective the robots, which made this movement, worked. In sum, the deviations were pretty high, but with a median regulation, this movement could have been regulated in a way, that it would show only minimal deviations when worn. For a movement of the lowest class, a pretty good result.

crown right (12 up)

crown up (3 up)

crown left (6 up)

crown down (9 up)

dial up

dial down

| horizontal positions | |

|---|---|

| dial up | -32 s/d |

| dial down | -10 s/d |

| vertical positions | |

| crown right (12 up) | -60 s/d |

| crown up (3 up) | -90 s/d |

| crown left (6 up) | -60 s/d |

| crown down (9 up) | -5 s/d |

Technical data

| Manufacturer: | EB |

| Caliber: | 8503-76 |

| Size: | 11 1/2''' (measured: 26,4mm) |

| A/h: | 21600 |

| lift angle: | 45° |

| Number of jewels: | 17 |

| Escapement: | Pin lever |

| Balance types: | Nickel anular balance |

| Shock protection(s): | Novodiac |

| Balance bearing / direction hairspring: | Bridge |

| Moveable stud: | no |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | pillar construction |

| Winding mechanism: | special winding system |

| Features: |

|

| Production period: | 1976 - ? |

| Data sheet: | 1978 |

Usage gallery

Links

- US Patent 3,896,614 (Patent of the balance bridge)

- US Patent 4,291,401 (Patent for the dial mounting of this movement)