Description

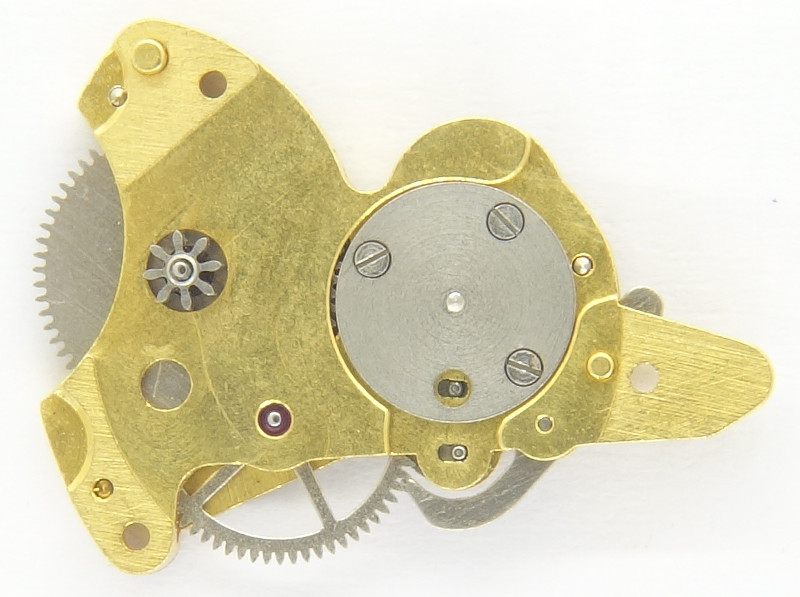

In the early 1960ies, Felsa released their one but last series of selfwinding movements, and they could be seen as the top of their movement developments.

The Felsa 4002 is the model with date indication, but without a quickset function.

The visually most applealing type was gilt, which perfectly matches the rich equipment with ruby bearings. Except the non friction-prone bearing of the mainspring barrel, all bearings are of course ruby-equipped.

It’s striking, how few place the gear train and balance use; about one third of the available space remains unused.

The directly driven center minute wheel is beared under an own bridge. This kind of construction was no longer really cutting edge technology, but it was proven for decades.

Interestingly, the crown wheel is not part of the winding bridge, but is located on the inner side of the gear train bridge.

We have an old-fashioned gear train on the Felsa 4002: The large mainspring barrel drives the center minute wheel, followed by third wheel, seconds wheel (at 6 o’clock, so in theory, it could carry a decentral seconds hand on the dial side) and finally the steel escape wheel.

The third wheel consists of two concentric gears of equal side, but having a little offset, so tha the center seconds pinion does not flutter or jump. It works perfectly!

On the specimen shown here, the balance wheel is top quality, it is a large Glucydur screw balance. It’s a bit sad, than only a flat hairspring was used, and that there’s no fine adjustment of the hairspring length possible. The precise beating frequency of 18000 A/h can only be adjusted with the hairspring key directly. It would have been the icingon the cake, if Felsa hat used a Breguet hairspring with a swan neck regulator.

Of course, the balance wheel is shock protected. It cannot be determined with certainly, which type of two-leg shock protection is used here.

Without selfwinding module, the Felsa 4002 is equal to the Felsa 4012. You can nicely see, how the engagement of the selfwinding module with the crown wheel happens at position 8:30.

The selfwinding module consists of a rocking bar changer, a transmission wheel, which is secured by a ratchet plus click spring, and the transmission wheel, which drives the crown wheel.

The dead angle of the oscillating weight is pretty big with about 60°.

Both transmissions wheels are fully ruby beared, but not the two wheels of the rocking bar changer.

On manual winding, the decoupling of the rotor happens on the rocking bar changer, which means, that the two transmission wheels and the ratchet have got a lot to do. No idea, why Felsa did not use for example a beguet clutch on the first transmission wheel. A small faux-pas on the otherwise so well constructed movement.

Pretty usual for Felsa was, that the oscillating weight is axle-beared. It has got a heavy metal inlay, probably lead.

The fixed axle runs within the ruby bearing of the oscillating weight. It is mounted with three screws and in case of a breakage, it can be exchanged easily, as long, as spare parts are available.

The calendar mechanism on the Felsa 4002 is pretty simple and has got no correction mechanism at all. So, in a bad case, you have to turn the time forth or back for fifteen days to reach the correct date. Later versions of the movement (caliber Felsa 4007) at least offered a semi fast correcting mechanism.

On the other hand, the locking of the date ring is very well made: A flat and beared metal ring is pressed against the teeth of the date ring with the help of a secured spring. No flying parts, that’s what watchmakers love!

The setting lever of the Felsa impressed with its very rugged construction, and so, the dial side also offers a very pleasant view for the watchmakers’ eye.

In the lab

The specimen shown here came gummed and with a large beat error into the lab. It was a movement without case, because it most probably had a golden case, which was melted and destroyed. What a pity!

It was cleaned, olied and adjusted.

Timegrapher result

For the fact that the work was in rather bad condition (“slaughter movements” are usually not handled carefully), and already 60 years old, it showed exceptionally good precision values on the timegrapher. In five of the six position, the daily deviation is lower than ten seconds, and the constantly low beat error on all positions also are a proof for the high quality of this movement.| horizontal positions | |||

|---|---|---|---|

| dial up | +17 s/d | 245° | 0.1ms |

| dial down | -7 s/d | 298° | 0.3ms |

| vertical positions | |||

| crown right (12 up) | -4 s/d | 213° | 0.2ms |

| crown up (3 up) | +5 s/d | 209° | 0.3ms |

| crown left (6 up) | -9 s/d | 202° | 0.1ms |

| crown down (9 up) | -9 s/d | 204° | 0.4ms |

Technical data

| Manufacturer: | Felsa |

| Caliber: | 4002 |

| Caliber base: | Felsa 4000 |

| Size: | 11 1/2''' |

| A/h: | 18000 |

| Number of jewels: | 25 |

| Escapement: | Pallet lever |

| Balance types: | Glucydur screw balance |

| Shock protection(s): | 2 legs (generic) |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 1 hole |

| Features: |

|

| References: | Flume: K2 1962 71 |

| Inventory number: | 20001 |