Description

The final series of selfwinding movements by GUB carried the name “Spezichron” was built between 1978 and 1985 in almost 400.000 units.

Compared to its relative, the GUB 11-26, which was sold in large quantites by the West German mail order form “Quelle” and only showed the data, the GUB 11-27 a day-date indication, but was produced in much smaller quantities.

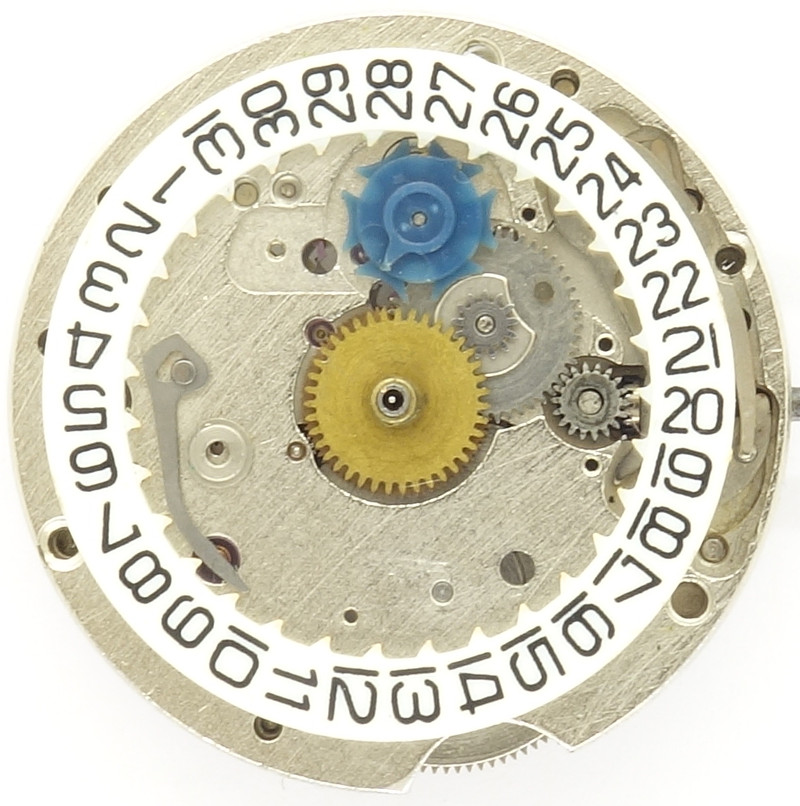

The base plate of this 11 1/2 ligne movement shows its modern construction: The tiny brass bushing in the center of the movement is only used for bearing the center seconds axle; the hands, respective the minute wheel, are driven indirectly on the dial side by the third wheel at position 3:30 o’clock pretty near the center. This construction, which is mainly familiar from ETA movements, allows a very large mainspring barrel, which is an advantage on a fast beating movement.

So, the gear train of the GUB 11-27 is the following one: Mainspring barrel - great driving wheel - third wheel - directly driven center seconds wheel - escape wheel. The latter one has got 20 teeth.

The three leg anular balance of the GUB 11-27 with its slanted legs could be an in dication of a Glucydur balance. But since the balance is silver colored, it is not sure, of which material it really consists.

What is certain, however, is the fast beating rate of 28800 A/h, which made the movement technically absolutely competitive. Unfortunately, there’s no fine adjustment, so that the effective length of the hairspring could be adjusted only directly with the hairspring key.

The ratchet wheel has got an axle with a square at the end of it, which injects into the mainspring barrel core. Since it is only one single part, there’s no need for a screw on top of the ratchet wheel, which reduces the height of the movement, which builts relatively high, a little bit.

When the three-quarter plate is put on top of gears, you can see the partially engraved bearings for the selfwinding mechanism. Here, a little height could be saved, too.

The selfwinding gear train consists of three gears. The oscillating weight drives the first one, which has got a role locker mechanism, compared to that of a Wostok 2416, but with steel roles instead of ruby roles. In any case, it ensures, that the oscillating weight only winds in one direction and spins free in the other one.

Gears two and three are gear wheels, the last one drives the ratchet wheel.

The first wheel of the selfwinding mechanism is locked by a very small spring with very good flying characteristics against turning in the “wrong” direction.

The oscillating wheel is ball beared. Its size changed during the production period, for cost saving reasons, the rotor segment had to be reduced.

On the empty dial side, you can see the yoke winding system and at 8:30 the drive of the third wheel, which engages with the minute wheel on the dial side.

As on many movements with indirectly driven hands, the cannon pinion is connected with the minute wheel by a slipping clutch, there with two paralle spokes.

The change wheel of the hands train turns five times per day. The date star switching wheel at 12 o’clock is executed in that way, that it makes five steps (each 1/5 revolution) in 24 hours. The finger on its upper side engages with the date wheel and advances it semi-fast. By turning back the time, it slips, so that the date can be corrected semi-fast. The secong switching finger of the star switching wheel, which is on the opposite side, switches the weekday disc forth and also back.

Unfortunately, the date indication mechanism is covered by a contoured plastic disc. Since this disc is very thin and unstable, it is predetermined that the date indication mechanism will fail sooner or later.

Really worse is the spring for the blocking lever. To hold it in position, the plastic cover must have been mich more stable. Since this is not the case, it cannot press the blocking lever reliably against the noses of the date ring.

The weekday disc is, like the date ring, also made of plastic. On its inner side, it has got fourteen half discs, which engage with the blue switching wheel. The spring-loaded ring at 8 o’clock is responsible for locking the weekday disc in position.

When the plastic cover of the date indication mechanism no longer sits properly (which happens sooner or later), the weekday disc is no longer properly beared and the spring-loaded ring gets below the half discs and the weekday disc can no longer properly indicate the weekday.

Normally, the GUB 11-27 should have become a success, with its features and fast beating escapement it was compareable with swiss movements and it was even much cheaper.

Unfortunately, the terribly executed date indication mechanism with its way too fragile plastic parts ruined the movement and so it was hardly used outside the GDR. Today, properly working specimens are really rare and spare parts, made of plastic, don’t help here either.

Technical data

| Manufacturer: | GUB |

| Caliber: | 11-27 |

| Size: | 11 1/2''' (measured: 25,6mm) |

| A/h: | 28800 |

| Number of jewels: | 22 |

| Escapement: | Pallet lever |

| Balance types: | Nickel anular balance |

| Shock protection(s): | GUB (Glashütter Uhrenbetrieb) |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 3 holes |

| Features: |

|

| Production period: | 1979 - 1985 |

| Inventory number: | 20010 |