Description

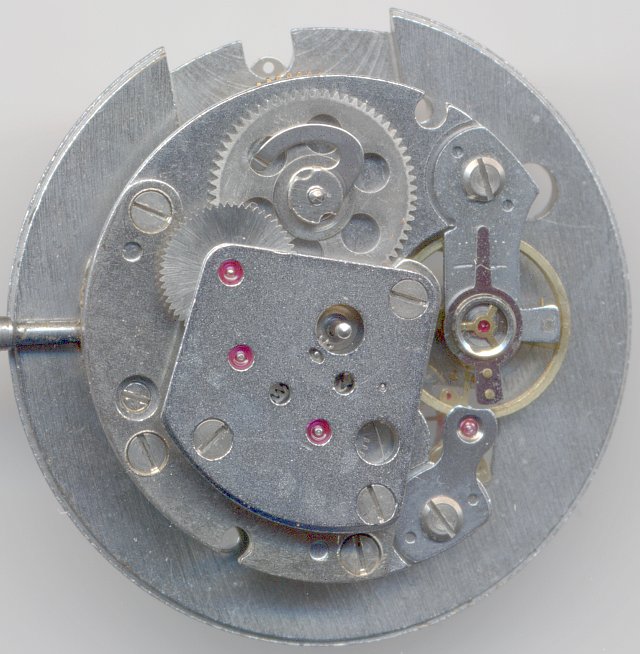

The Kienzle caliber 057/21d, the so-called Volksautomatik, which was launched in the mid fifties, was the only inhouse selfwinding movement of the german watch factory, located in Schwenningen.

Video on YouTubeUnlike the handwound watches by Kienzle, the Volksautomatik cost with 65.- DM twice as much, what is the reason, why it is relatively rare and already put out of production in 1963.

The caliber 057/21d is a real inhouse construction, which had a better quality, than the handwound movements.

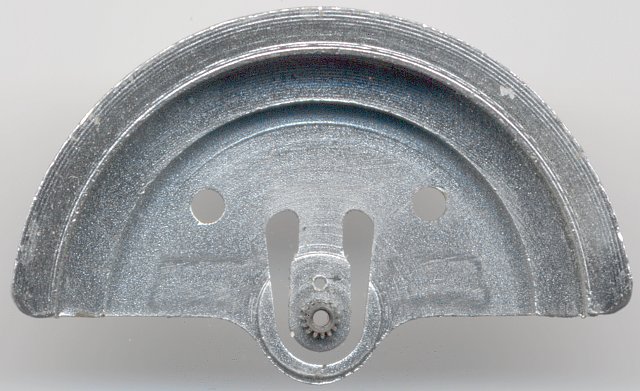

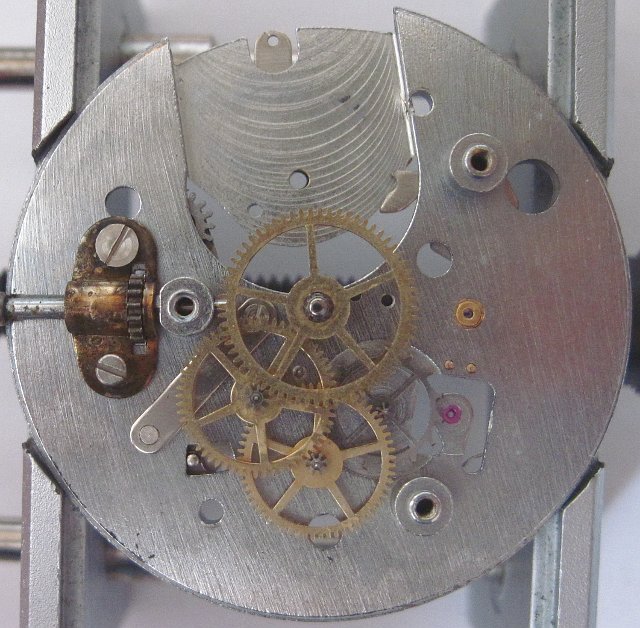

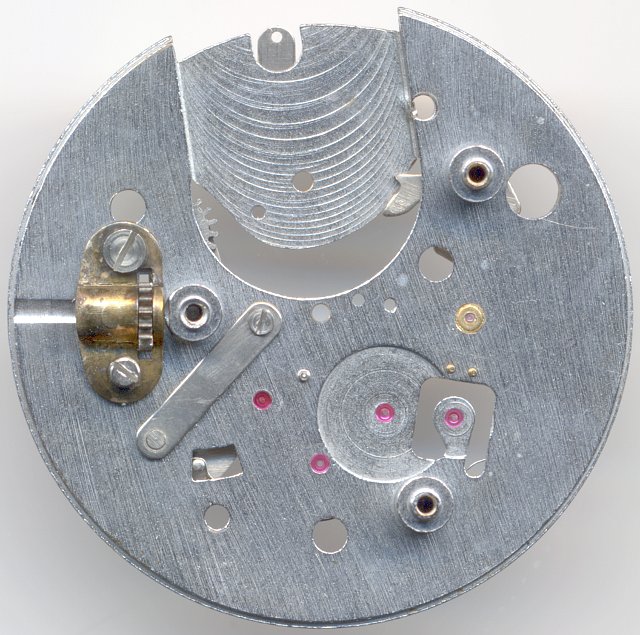

The oscillating weight is axle-beared and contains a lead circlet.

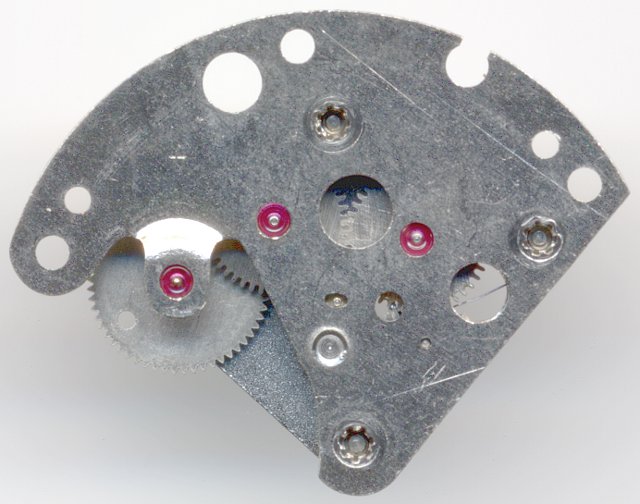

The selfwinding mechanism can be released as a unit from the movement by removing three screws.

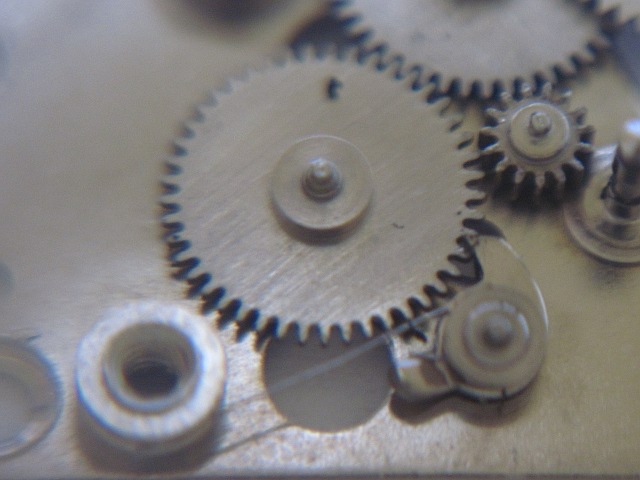

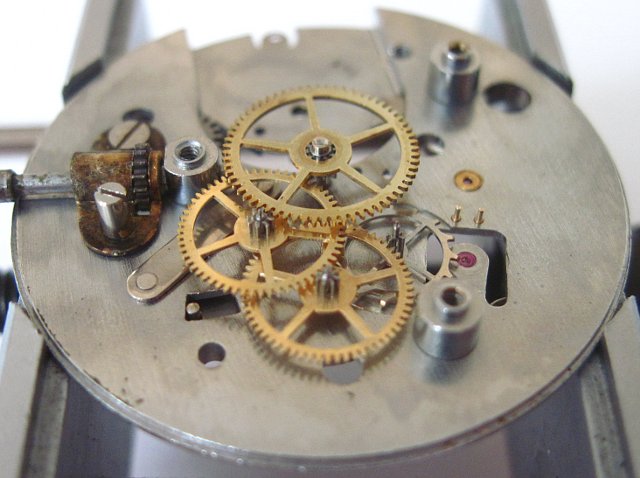

The flying beared changing wheel, which is driven by the oscillating weight, drives in both directions one of the two wheels and realizes the bidirectional winding. The disadvantage of this solution is, that it has got a rather long empty running way, so when the oscillating weight changed its direction, it spins freely quite a long time.

The upper ratchet wheel is exclusively driven by the selfwinding mechanism with the help of a reduction wheel.

The click on the leftmost driving wheel avoids unwanted running down.

With the exception of the flying beared wheel, all other gears are located in ruby bearings.

A coupling, which is simple and genious the same time is used for the upper ratched wheel: Not the ratchet wheel, but only the barrel axle with its connected slide coupling in attached to the barrel arbour. When manually wound, it decouples the selfwinding system; when wound by the oscillating weight, it connects.

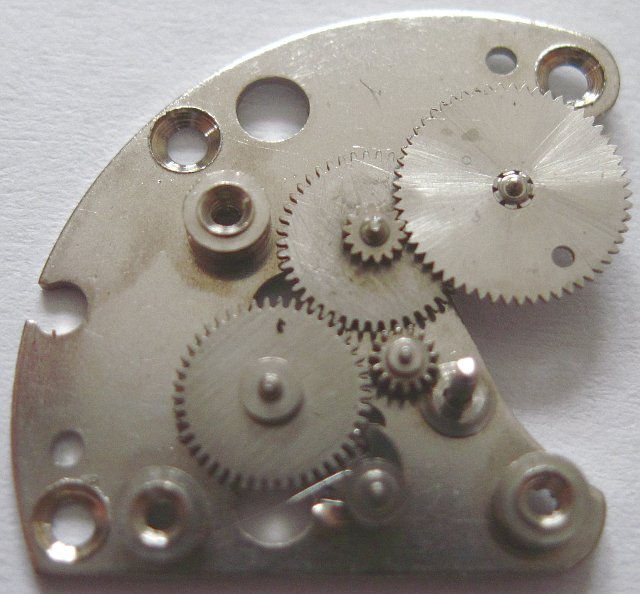

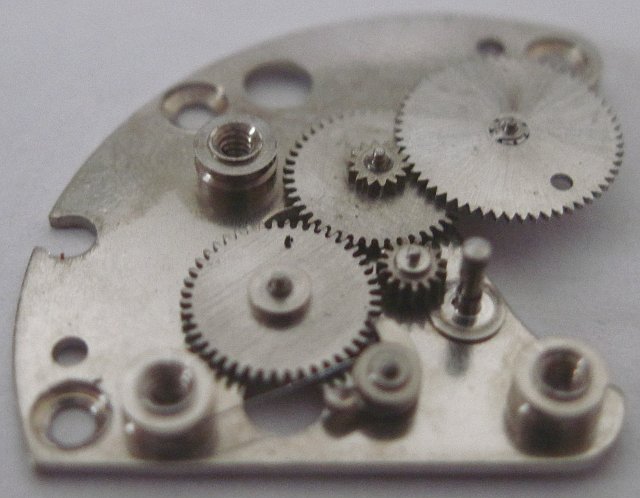

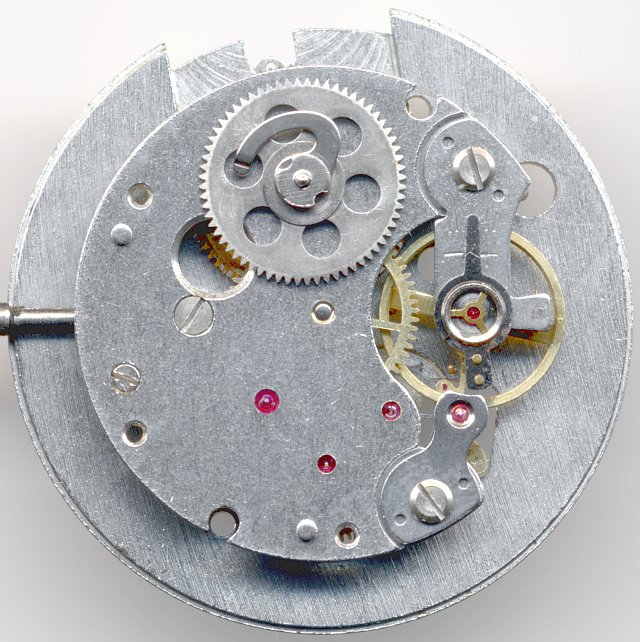

As you can see, the wheel mechanism of the Kienzle 057/21d bases on the caliber 48.

The time mechanism consists of: Mainspring - minute wheel - third wheel - fourth wheel (decentral second ) - escapement wheel.

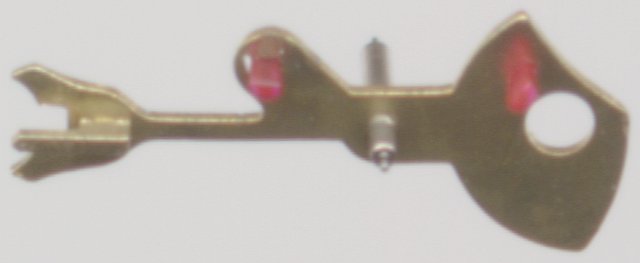

The Kienzle 057/21d uses a ruby pin-lever, which is developed inhouse. It’s a good compromise between the expensive and sophisticated swiss pallet lever and the cheap, but unprecise pin lever with metal pins.

The pins have got the shape of half of an cylinder, of the escapement wheel teeth match perfectly.

According to Kienzle, this type of escapement shall be equivalent to a swiss pallet lever excapement.

Of couse, on this movement, all bearings contain rubies; the ring balance is secured by two inhouse shock protections, where the protection on the dial side only offers protection against frontal shocks and not against side shocks.

The mainspring barrel with its towing spring can be released as a whole by pulling a spring at “12”.

On the dial side, you can see the rocking bar winding mechanism and the click mechanism. It is a well made construction.

A very odd detail are the dial feet, which are held by screws(!) on the movement plate.

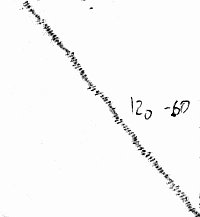

Timegrapher result

The specimen tested here came into the lab without case. It got a full service, but the oiling of the escapement pins was non trivial and maybe not optimal done, too. The timing results are quite OK, especially for a pin lever movement. Probably due to the problematic oiling of the release pin, they are worse than they have to be.

crown right (12 up)

crown up (3 up)

crown left (6 up)

crown down (9 up)

dial up

dial down

Technical data

| Manufacturer: | Kienzle |

| Caliber: | 057/21d |

| Size: | 12 3/4''' (measured: 29,6mm) |

| A/h: | 18000 |

| Number of jewels: | 21 |

| Escapement: | Pin lever |

| Balance types: | Nickel anular balance |

| Shock protection(s): | Kienzle |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | no |

| Adjust mechanism: | Long regulator arm |

| Construction: |

|

| Construction type: | pillar construction |

| Winding mechanism: | rocking bar winding system |

| Setting lever spring: | 2 holes |

| Features: |

|

| Production period: | 1956 - 1963 |

| Mentioning in literature (years): | 1960 |