Description

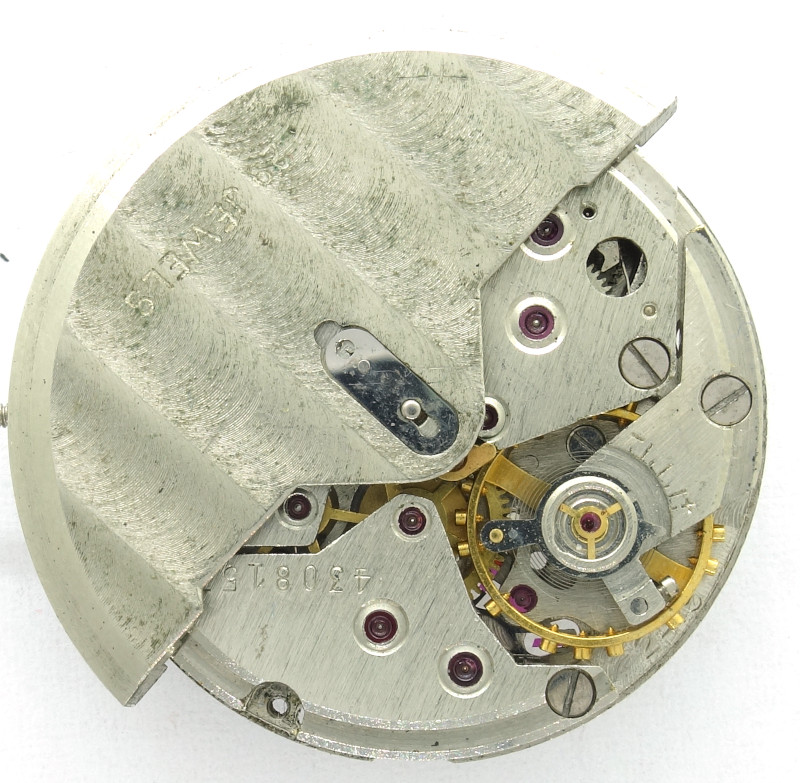

In 1962, the First Moscow Watch Factory (1MWF) released the caliber “Orbita”, later renamed to “Poljot 2415”. With a height of only 3.9mm, is was the thinnest selfwinding movement with full rotor at that time, and had a number of construction oddities, which were so elaborate and expensive, that the production ceased in 1971 already.

Even though the movement had a nominal diameter of 24mm, this was meaningless in reality, since the rotor overlapped the movement by far and so, you could only use the movement together with its retaining ring, which gave the whole construction a diameter of 30mm.

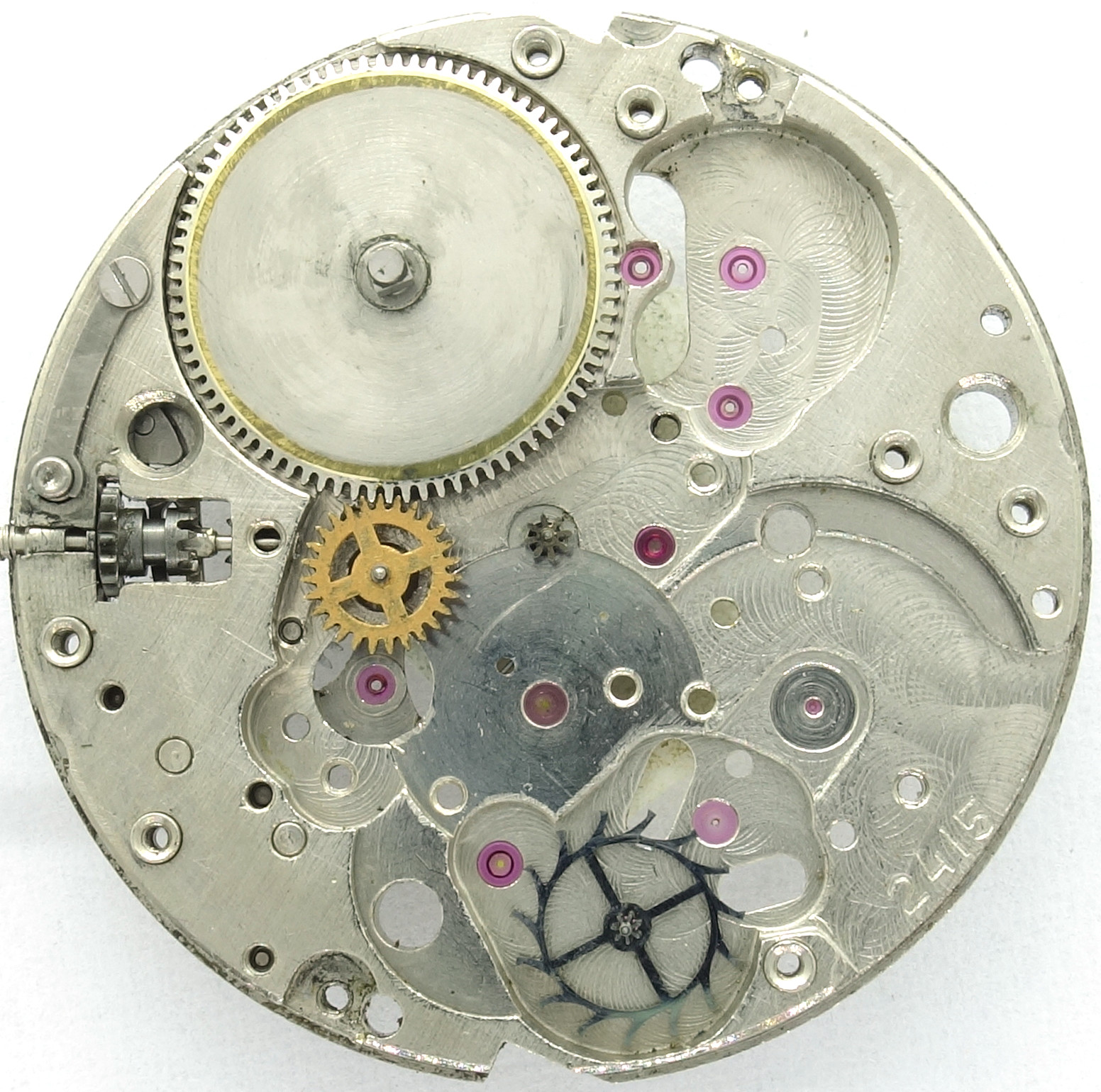

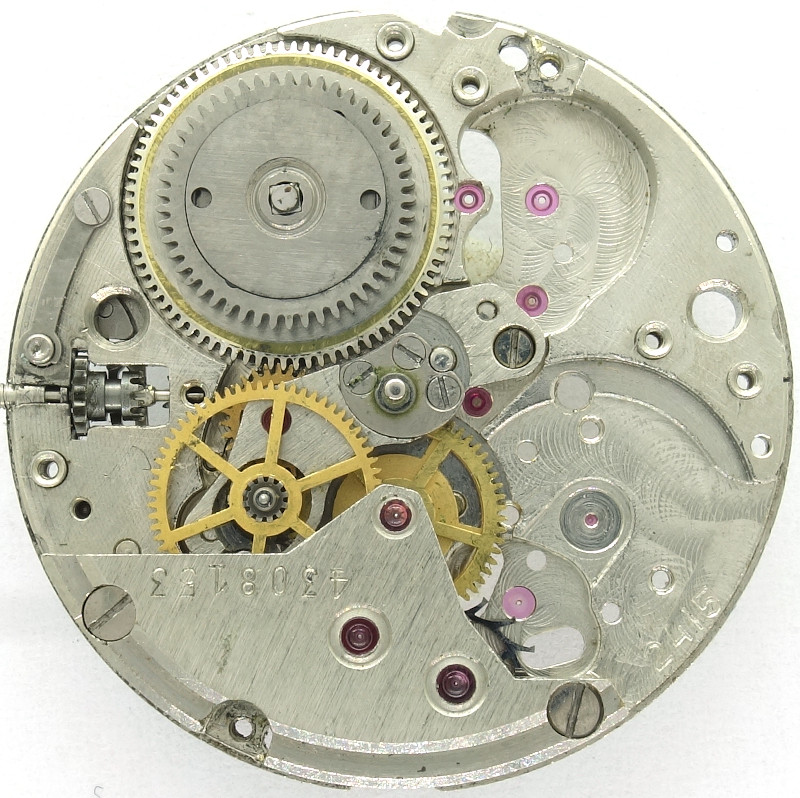

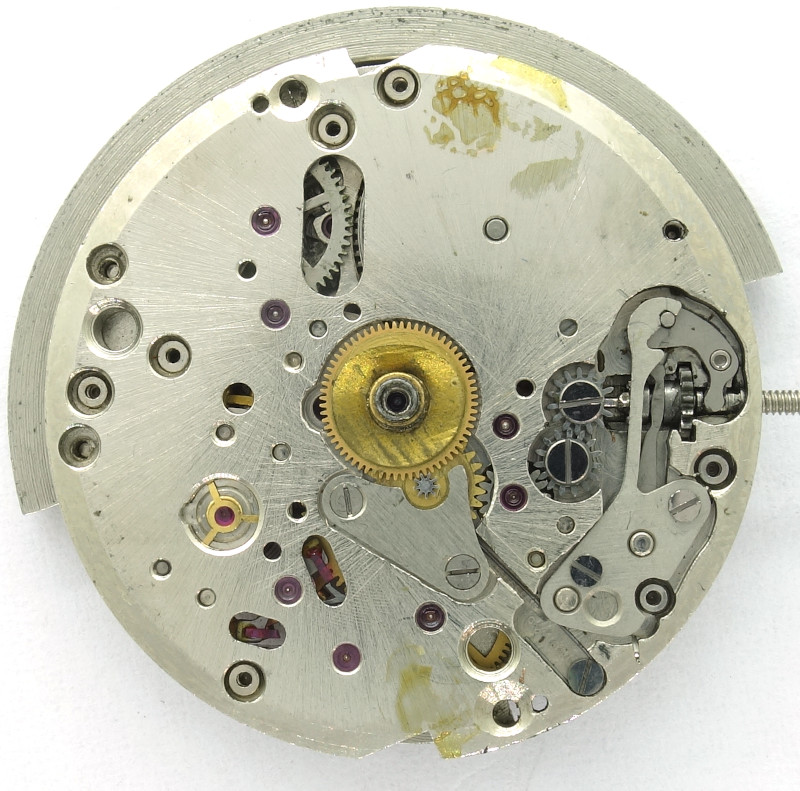

Bearing jewels, wherever you look. This is, what you will immediately recognize when you look at the base plate. Its execution is pretty raw, but technically, that’s not a problem.

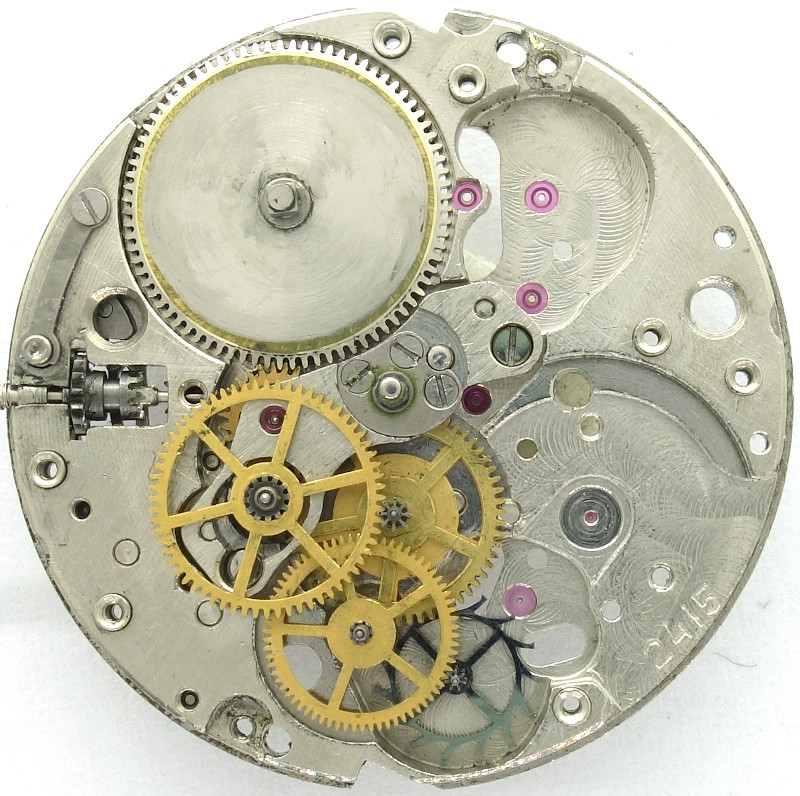

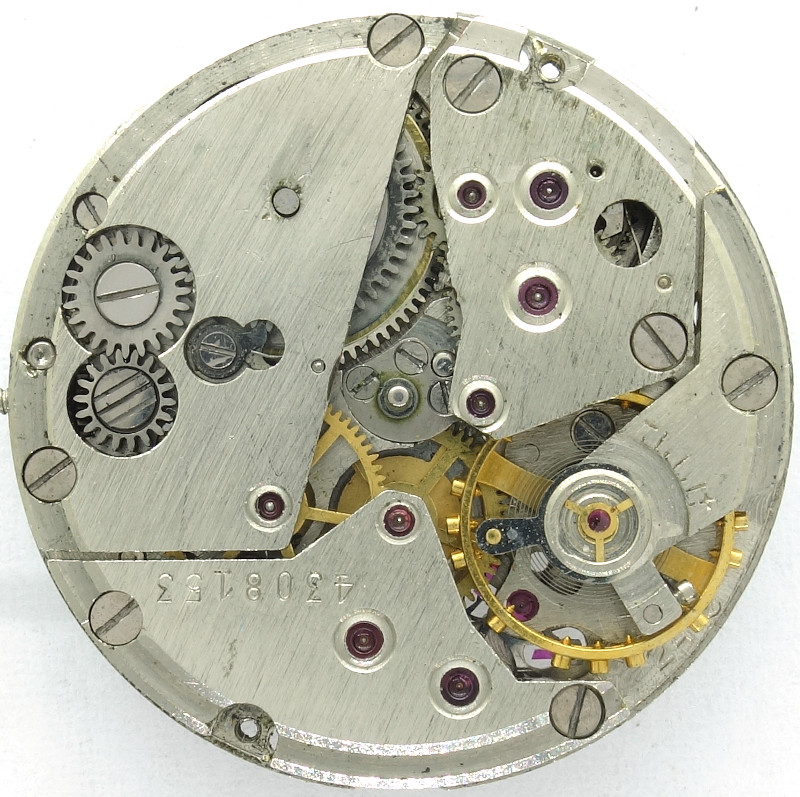

To build as flat at possible, while having a large balance wheel and mainspring barrel, the Poljot 2415 doesn’t use a center minute wheel, but drives the hands on the dial side only.

For this, the mainspring barrel engages with a transmission wheel, which itself engages with the second wheel, whose pinion drives the hands on the dial side. Details later.

Transmission wheel and center seconds pinion are beared under their own bridge, on whose upper side, the axle bearing for the selfwinding mechanism is mounted.

The second wheel is followed by a double third wheel, seconds wheel and escape wheel.

The third wheel, which drives the center seconds pinion, is a double one to reduce fluttering and jumping of the seconds hand without adding additional friction.

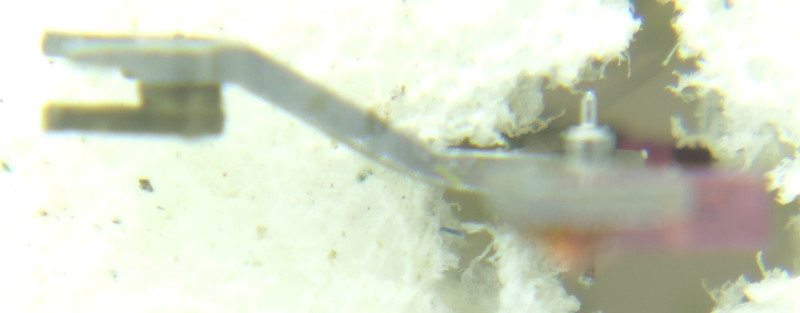

The design of the pallet lever is really odd: The pallets and the fork are in different heights!

As balance, a golden toned, two leg screw balance is used, probably made of Glucydur. It beats slowly with 18000 A/h, is beared in two russian three-arm shock protections, and the effective length of its hairspring can be regulated with a short regulator arm, or better, at the hairspring key directly.

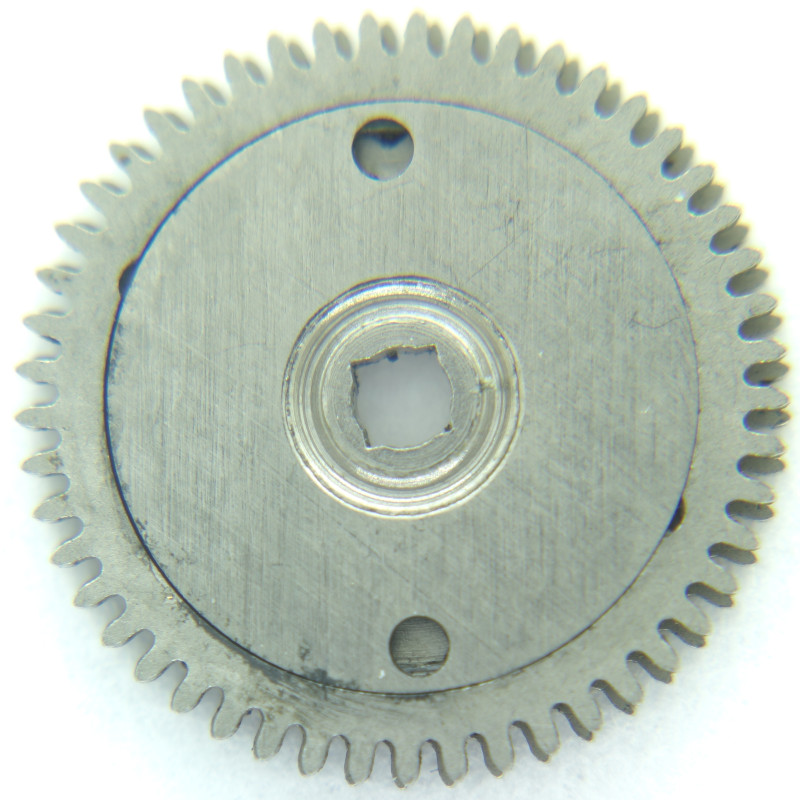

The Poljot 2415 uses a double ratchet wheel with a built-in clutch which disengages the selfwinding mechanism, when the movement is wound manually.

The ratchet is located in a recces of the barrel bridge.

You see the large wear and tear and the runout bearing, which forces are working here. A ruby bearing would have been a better solution.

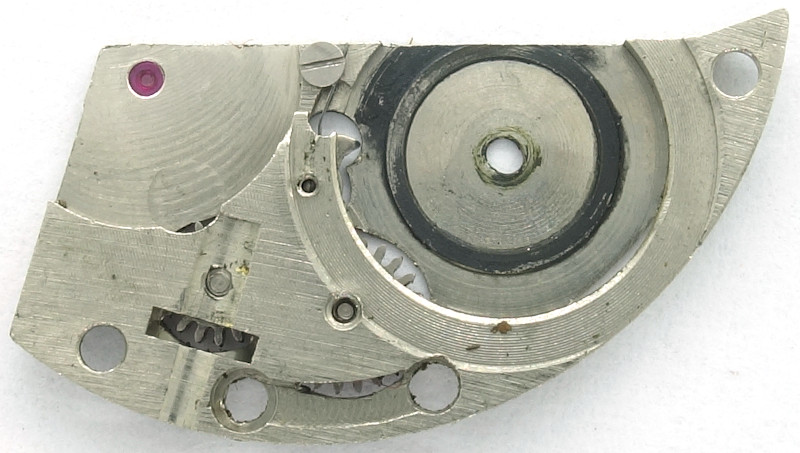

The whole selfwinding gear train is mounted on the base plate of the movement. This allows its reduced height of only 3.9mm.

Lots of effort were done for the selfwinding mechanism. The oscillating weight with builtin rocking bar changer drives either the first changer gear or the first reduction wheel, also driven from the changer. Then, a second reduction gear and a transmission gear follow, where the latter one engages with the lower part of the double ratchet wheel.

There’s a ratchet with click for the first reduction wheel, to ensure, that the winding always happens in the same direction, regardless in which direction the oscillating weight turns.

As you can see, all gear trains are on the same height.

Inside the oscillating weight, there are two changer wheels, mounted on a rocking bar.

As said in the beginning, the hands are driven on the dial side, by the secod wheel pinion, which can be seen pretty near the center at position 4 o’clock.

This pinion has got a slipping clutch and also engages with the hands settings wheel through another transmission wheel.

Of course, the Poljot 2415 uses a yoke winding system. Its setting lever spring is, as often seen on russian movement, very rugged constructed.

There’s an oddity with the bearing of the changer wheel: A long spring (which starts at position 5 o’clock) adds a little tension. So, hour- and minute hand, which are both simultaneously driven indirectly by the changer wheel don’t flutter or stutter.

At position 8 o’clock, you can see the dial side shock protection bearing for the balance wheel, and next to it, the two recesses, through which the pallets of the lever can be inspected and oiled.

In the lab

Timegrapher result

As said, this movement is in a poor condition, technically and aesthetically, and hence performs way below its capabilities on the timegrapher.| horizontal positions | |||

|---|---|---|---|

| dial up | +13 s/d | 216° | 4.0ms |

| dial down | +6 s/d | 225° | 4.0ms |

| vertical positions | |||

| crown right (12 up) | +110 s/d | 163° | 5.6ms |

| crown up (3 up) | -20 s/d | 167° | 5.1ms |

| crown left (6 up) | +20 s/d | 172° | 5.4ms |

| crown down (9 up) | -60 s/d | 178° | 5.3ms |

Technical data

| Manufacturer: | Poljot |

| Caliber: | 2415 (Orbita) |

| Caliber base: | Poljot 2415 |

| Size: | 10 1/2''' (measured: 24,0mm) |

| Height: | 3,9mm |

| A/h: | 18000 |

| Number of jewels: | 29 |

| Escapement: | Pallet lever |

| Balance types: | Glucydur screw balance (two legs) |

| Shock protection(s): | 3 arms, russian |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | no |

| Adjust mechanism: | Short regulator arm |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 5 holes |

| Attachment of setting lever: | plugged |

| Features: |

|

| Production years: | 1962 - 1971 |

| References: | Flume: K3 169 |

| Inventory number: | 23080 |