Description

1977 the german PUW (Pforzheimer Uhrenrohwerke) launched their final series of mechanical movements, the series 660/1660. Although they were modern constructions and offered all possible standard features, they had no chance to compete with the upcoming quarz movements, and so in 1979 the PUW stopped the production of mechanical movements.

The caliber PUW 663 offers the highest number of features of the windup variants and offeres besides the center seconds indication also day-date display with a pretty unusually constructed quickset mechanism.

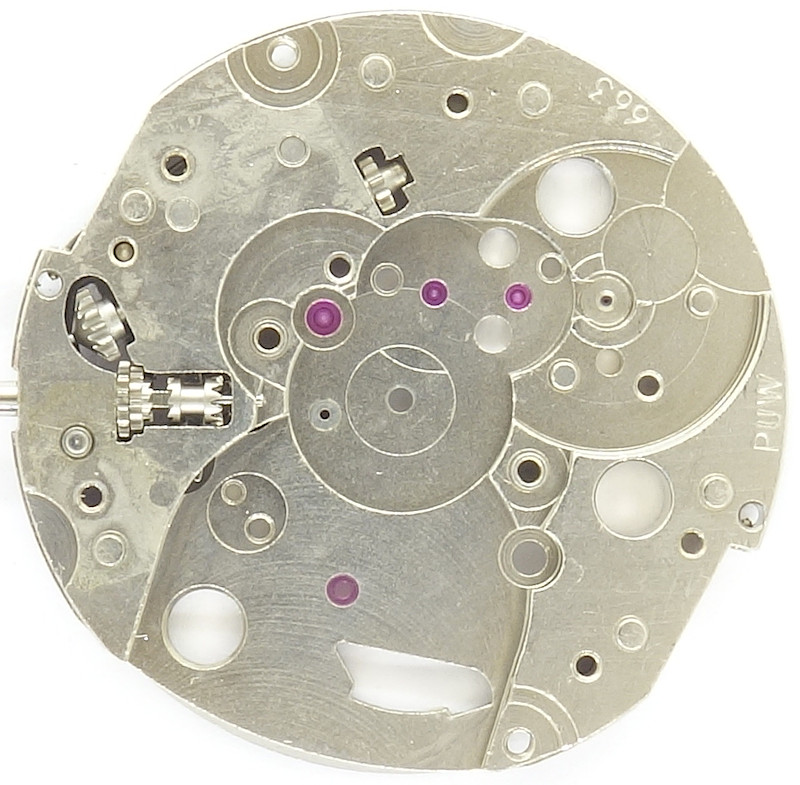

The base plate shows, that of course all important bearings contain Rubies, only the minute wheel is only ruby-beared on the dia side.

The date setting wheel arbour, which engages in the middle position of the crown, can be seen, too.

As all predecessors, the PUW 663 too, uses the classical gear train, with directly driven center minute wheel, which is beared under its own bridge. This bridge carries a bearing ruby, so that the minute wheel is ruby-beared on at least one side.

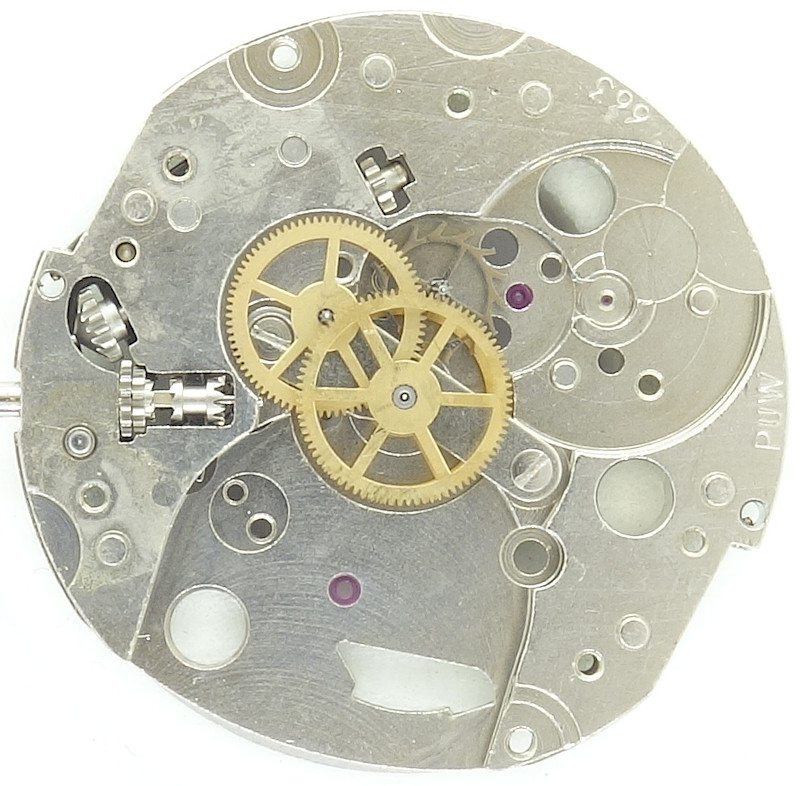

It’s typical for the final PUW caliber series, that the crown wheel is located on the innerside of the barrel bridge, and that it is riveted. This saves some space and was certainly cheaper to produce, but in case of an error, you most likely have to replace the whole bridge.

As said above, we have the classical gear train here: The large mainspring barrel drives the center minute wheel, followed by third wheel, center seconds wheel and steel escape wheel.

As regulating device, a screw-less, three leg anular balance is used, which beats rather slowly with 21600 A/h. Contemporary movements from ETA all beat faster with 28800 A/h and could achieve a better precision. Nevertheless, at least the Incablock shock protection is state of the art.

The hairspring adjustment happens on the hairspring key only, there’s no fine regulating mechanism.

Of course, a swiss pallet lever escapement is used.

The ratchet is located on the inner side of the gear train bridge. Unfortunately, it is also riveted, making it difficult to replace it in case of an error.

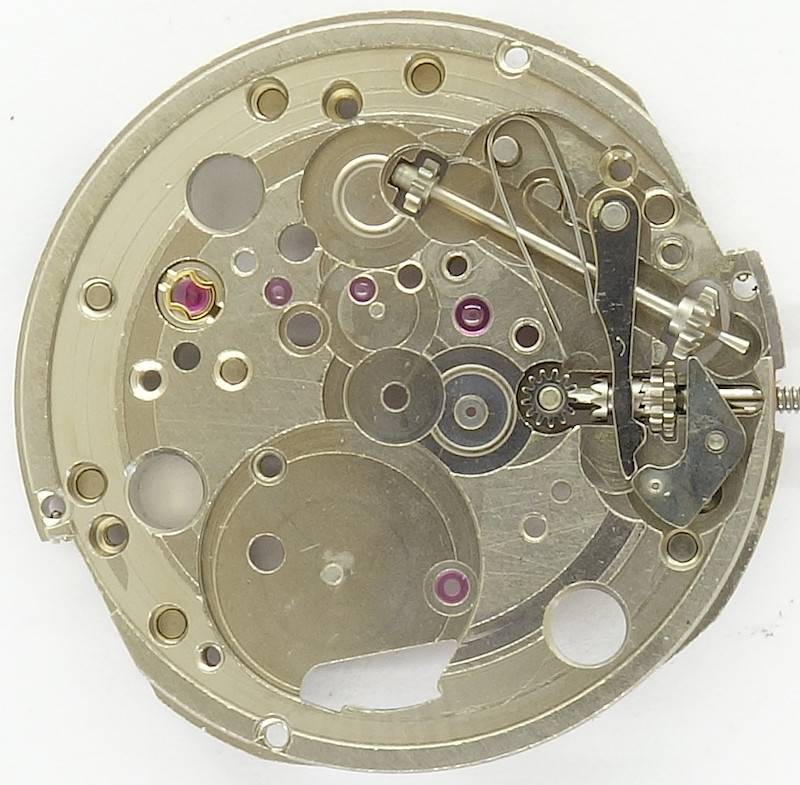

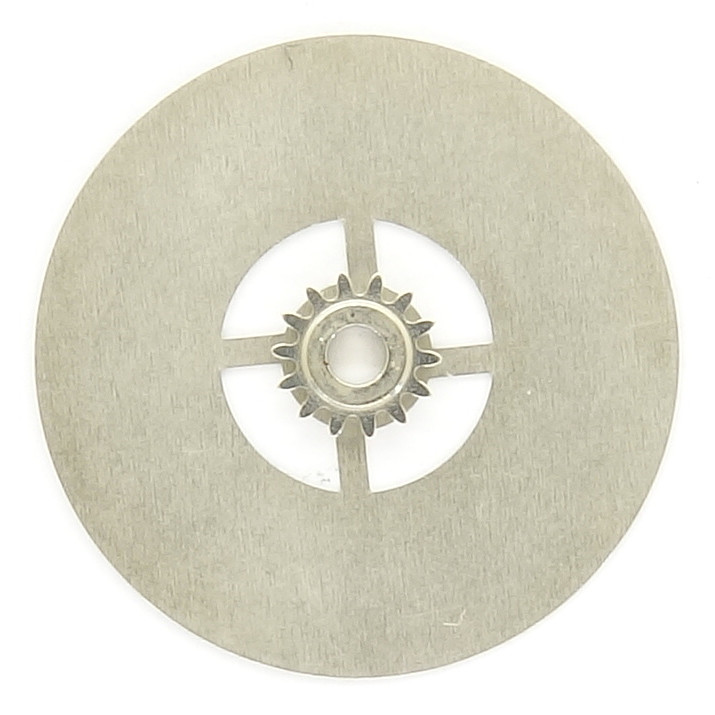

The most notable feature of the PUW 663 is its oddly constructed date quickset mechanism with a double double drive as main part.

In the winding position (crown pressed in), this double drive is disengaged and shifted away by the setting lever.

In the moddle position of the crown, the date double drive is engaged and can (see later) drive the date correcting mechanism.

When the crown is pulled out fully, the setting lever once again disengages the double drive by shifting it away, this time by its prolonged axle.

On the inner side of the date correcting plate, there’s a moving gear, which goes up or down, depending on the turning direction. If shifted up, the date ring is advanced, if shifted down, it turns a second, statically mounted gear, which drives the weekday disc.

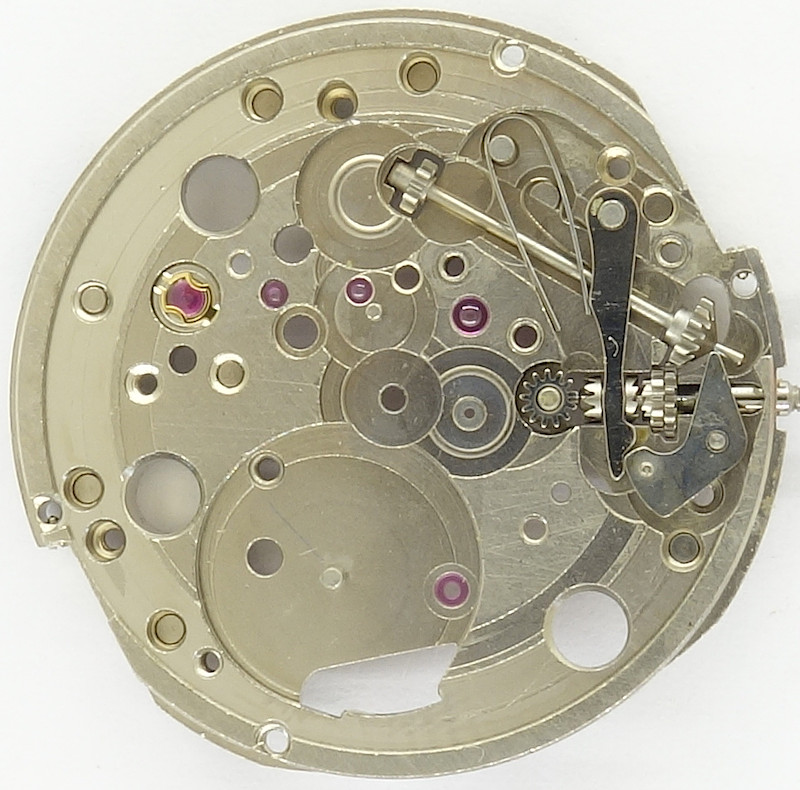

The regular date advancement happens via the ratchet wheel at 7 o’clock, which is driven by the hour wheel.

It has a lever and a pin, which are preloaded in corresponding cut-outs on the plate on the dial side, and discharge immediately at midnight. The long lever engages with the weekday disc, the pin into the date ring. The weekday disc must be advanced two steps, since it is bilingual.

The date mechanism is first covered with a semitransparent plastic spacer, on which another plate is located, which bears the weekday disc.

The bearing of the date ring is done with a cover plate, on whose inner side, a spring-loaded lever ensures, that the date ring locks at the correct position and thus the date figures are centered in the dial cutout.

Additionally, there’s a spring loaded flat metal ring, which locks the weekday disc in its correct position.

Here you can see very well, how at 6 o’clock the ping of the date switching wheel engages into the toothing of the date ring, and how near the center the long finger of the shift wheel engages in the weekday disc.

The lower side of the weekday disc has got the required toothing.

The PUW 663 has a bilingual weekday disc. The regular advancement with the switching wheel has to ensure, that it is driven two positions further. Only with the manual correction, the language can be switched, by advancing it only one instead of two positions.

As usual, the weekday disc is secured with a snap ring on the hour pinion.

In the lab

Technical data

| Manufacturer: | PUW |

| Caliber: | 663 |

| Caliber base: | PUW 660 |

| Size: | 11 1/2''' (measured: 26,0mm) |

| A/h: | 21600 |

| lift angle: | 52° |

| Number of jewels: | 17 |

| Escapement: | Pallet lever |

| Balance types: | Nickel anular balance |

| Shock protection(s): | Incabloc |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 2 holes |

| Features: |

|

| Production period: | 1977 - 1979 |

| Inventory number: | 20023 |