Description

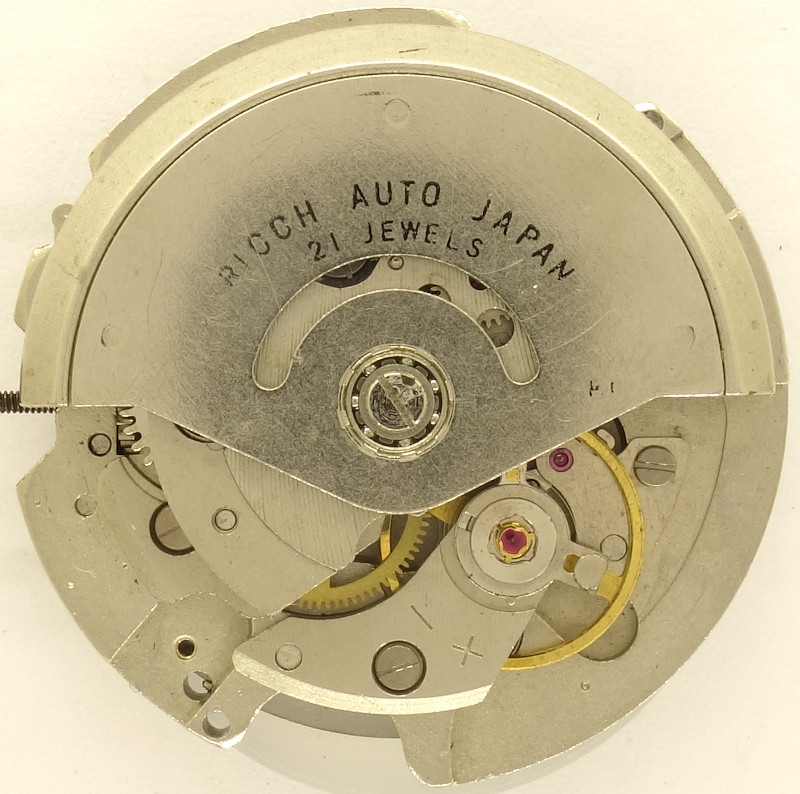

The Ricoh 61 from the caliber family Ricoh 30 is from the many selfwinding movements, which Ricoh made probably in the 1970s.

With its diameter of 12 3/4 lignes, it is a real full size movement.

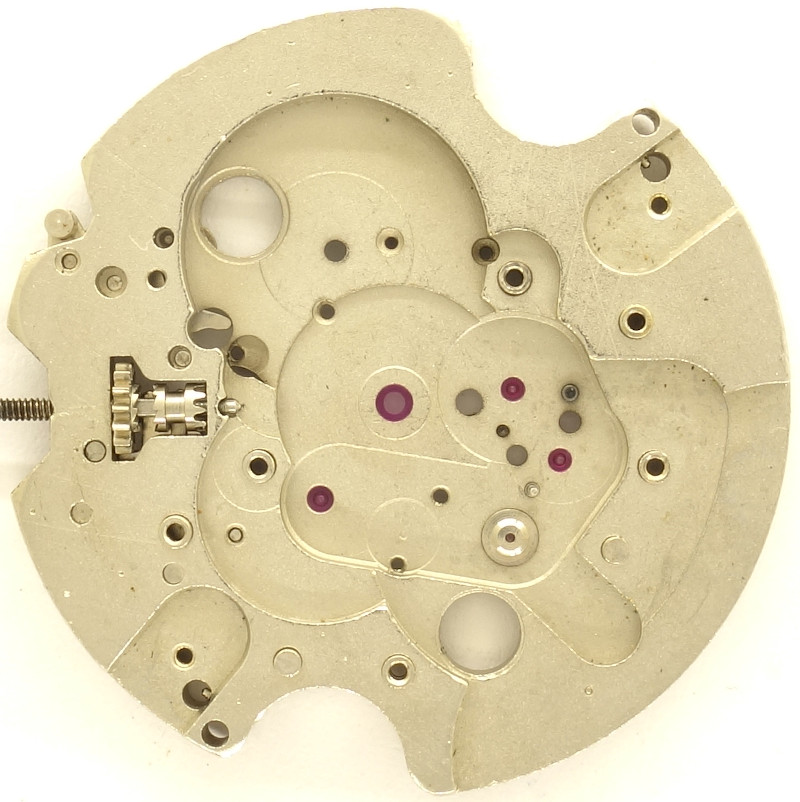

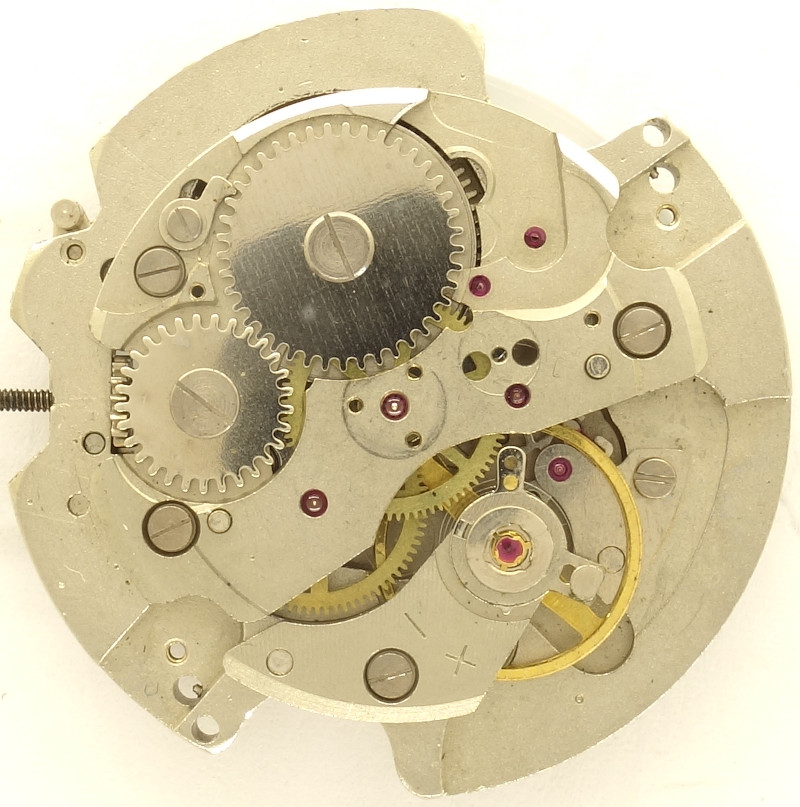

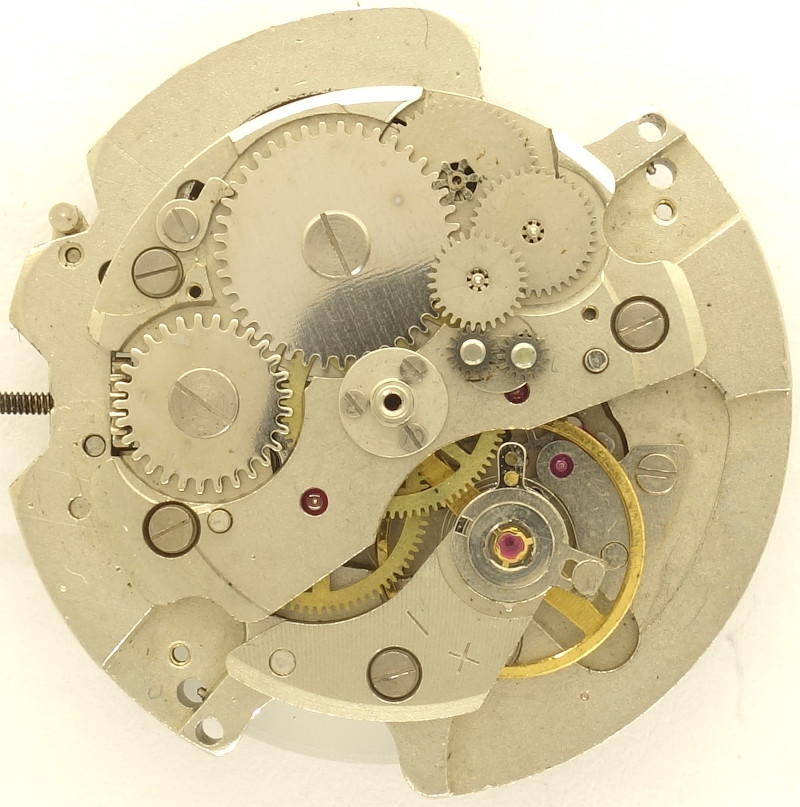

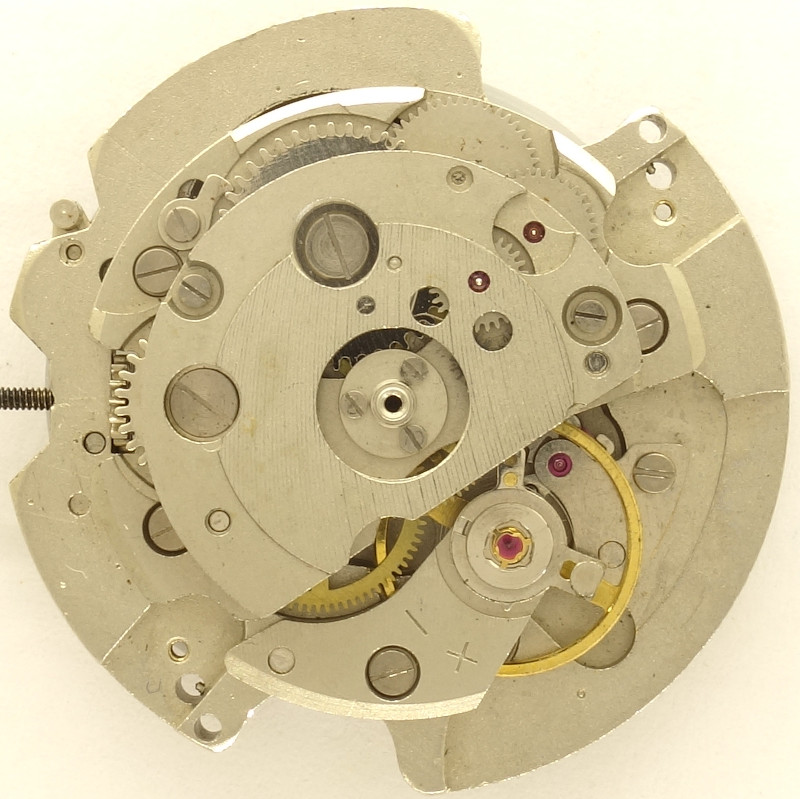

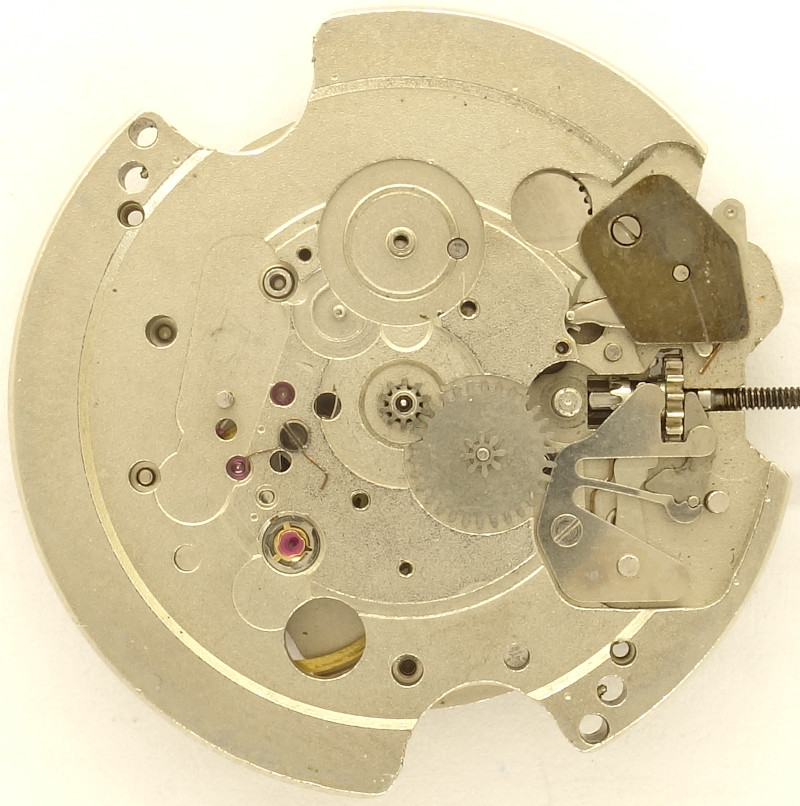

The base plate, which leaves lots of space unused, and which has got two indentations for access to the dial screws, shows, that all important bearings, including that of the center minute wheel, contain rubies.

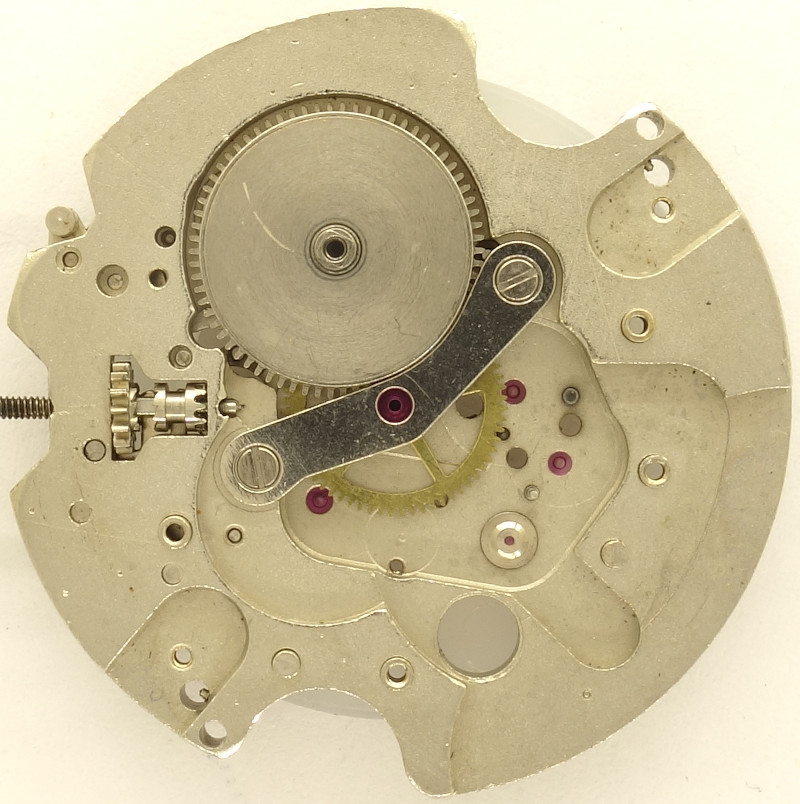

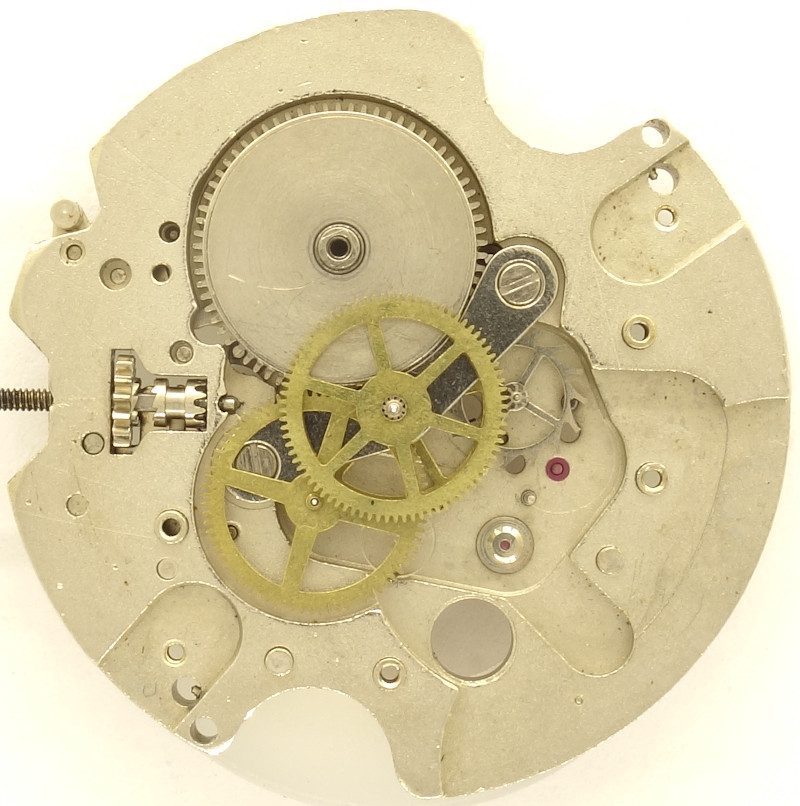

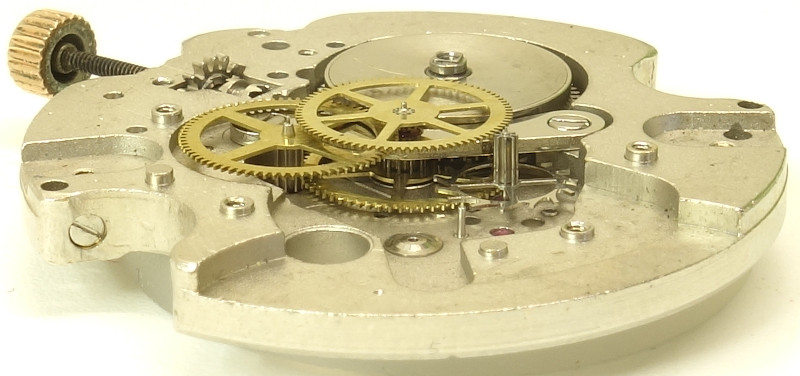

The center minute wheel, which is directly driven by the rather small mainspring barrel, is conventional state of the art.

The remaining part of the gear train is also a classical construction, with third wheel, directly driven center seconds wheel and escape wheel.

The pin above of the balance wheel bearing is noteable, details will follow.

The pretty thin wheels, which partially have got only four legs, remind of those of quartz watches.

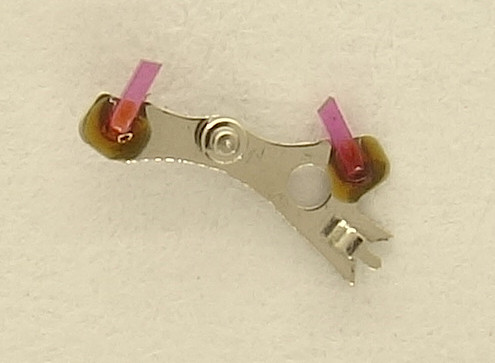

Anything but aesthetically pleasing is the execution of the lateral lever, a lever, which doesn’t use a conventional fork, but a stamped indentation at a 90° angle on one of its small sides. It is also very thin.

The hole in the prolonged long lever “form” is important: Into this hole engages the pin of the base plate, which was noted above, and limits the path of the lever.

This principle is known since a long time, the most popular usages are the movements from Glashütte, but there, the pin was mounted on the lever and the hole was within the base plate.

The monometallic, two leg anular balance beats slowly with 18000 A/h and can be adjusted only directly at the hairspring key. The balance wheel is beared in two rare to find Monorex shockprotections of the new type.

The selfwinding gear train consists of three reduction gears and a rocking bar changer, which, depending on the rotation direction of the oscillating wheel, either drives the first reduction wheel directly, or indirecty by the second rocking bar wheel. This mechanism ensured, that regardless of the rotation direction, the reduction wheels always turn in the same direction and wind up the movement.

The oscillating weight is even ball beared.

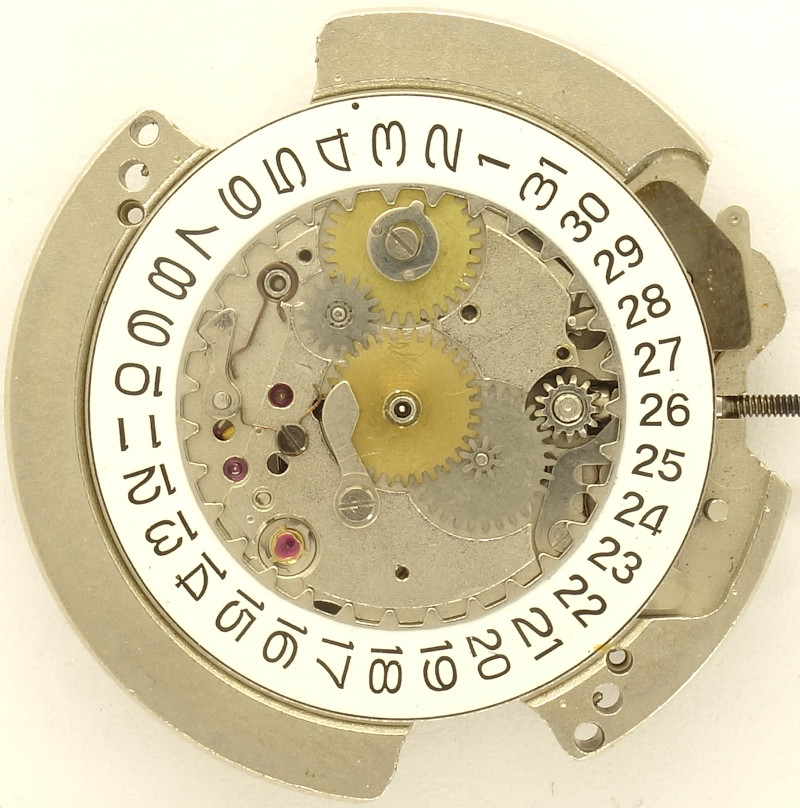

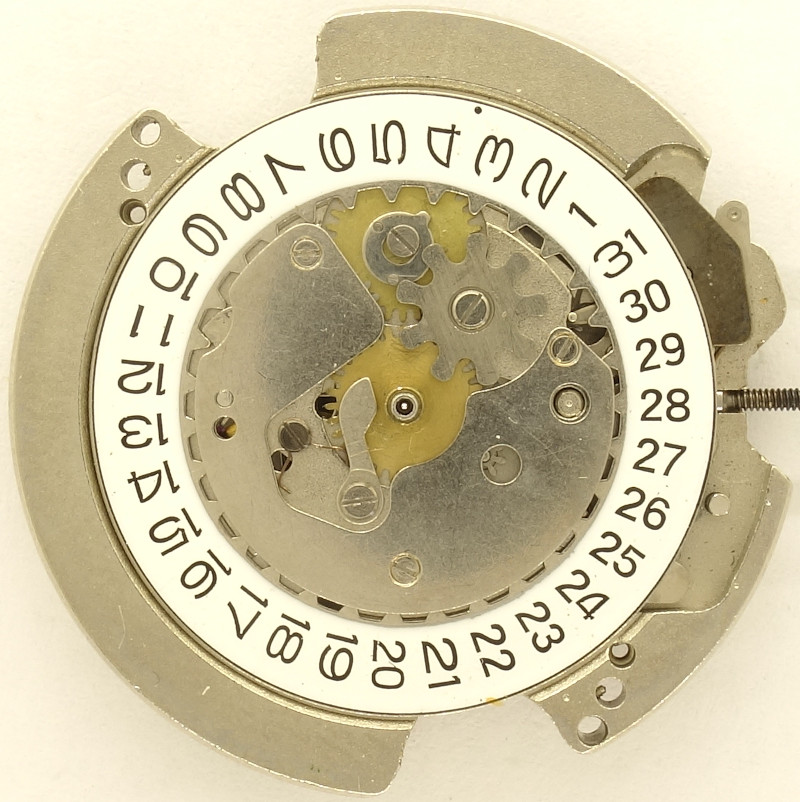

On the yet empty dial side, you see the yoke winding system and the lever mechanism of the date corrector, which is activated by pressing the lever at position 2 o’clock.

The moveable switching finger at 12 o’clock prevents, that a date correction during the regular date change harms the mechanism.

At 2 o’clock, you see the finger of the correction mechanism. Every press onto the corrector mechanism advances the date ring one position.

The lower pin of the switching finger drives the transmission wheel for the weekday indication and ensures, that date and weekday change more or less synchronously.

The Ricoh 61 uses a weekday disc, whose seven fields are on a ring, connected with seven spokey, outside/above the date ring.

On this way, the weekday can be fully printed, which, as you can see on the usage gallery, reminds strongly of the famous original, whose name also starts with an “R”.

Technical data

| Manufacturer: | Ricoh |

| Caliber: | 61 |

| Caliber base: | Ricoh 30 |

| Size: | 12 3/4''' (measured: 28,9mm) |

| A/h: | 18000 |

| Number of jewels: | 21 |

| Escapement: | Pallet lever |

| Balance types: | monometallic anular balance (two legs) |

| Shock protection(s): | Monorex (new) |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 2 holes |

| Features: |

|

| Inventory number: | 22017 |