Description

Tiny selfwinding movements for ladies’ watches were always a challenge. The situation was exacerbated in the 1960ies, when watches had to be extra flat, too.

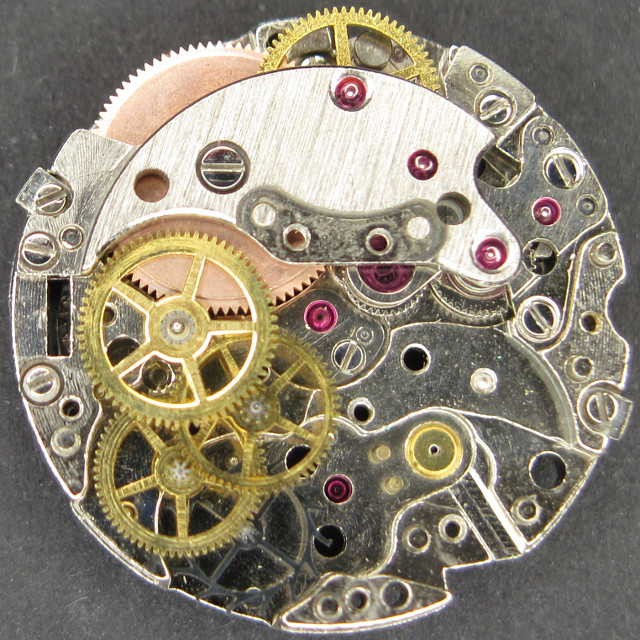

The pretty much only one selfwinding movement, which had a real small diameter (17.1mm = 7 3/4 lignes, that’s only a little bigger than a one Eurocent coin) and was flat at the same time, was the Buren 04, which was released in the late 1960ies and was the sister movement of the legenary “Slendermatic” microrotor movements.

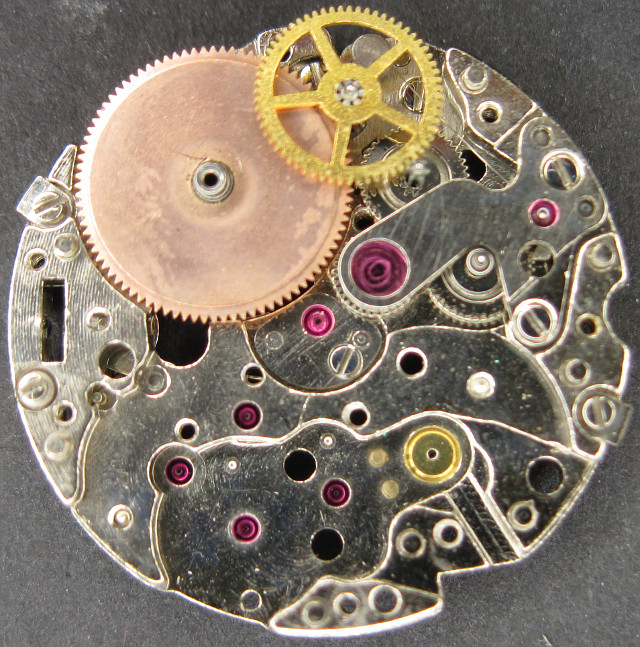

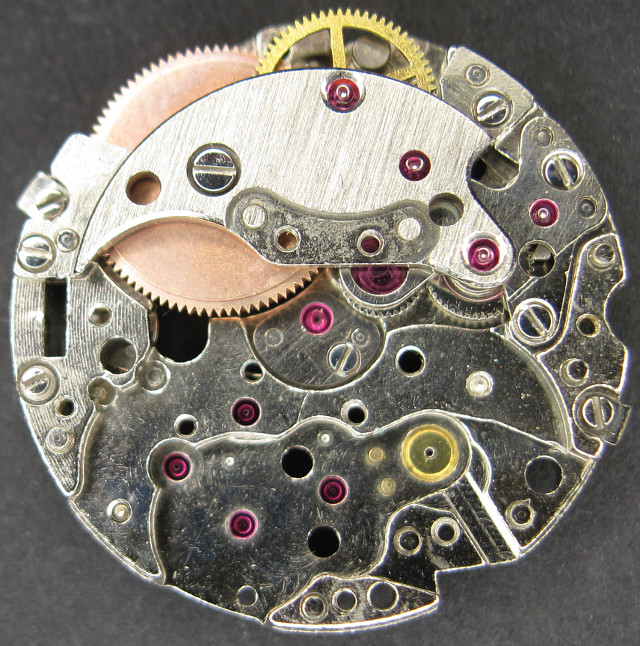

On the base plate, there are no less than 11 ruby bearings, this is easily twice the amount of “normal” movements and of regular selfwinding movements, too. Particularly striking is the large flat ruby, which is the bearing for the floating(!) pinion.

The gear train for the time indication (only hour and minute, no seconds indication!) consists of escapement wheel, fourth, third and second wheel. The latter one is equipped with a slipping clutch and drives the hands on the dial side.

The Buren 04 has got a three leg Glucydur anluar balance, which is beared in two KIF Ultraflex shock protections and which beats with 21600 A/h. It regulates a conventional swiss pallet lever movement.

The decoupling of the selfwinding mechanism happens with a flying beared wheel.

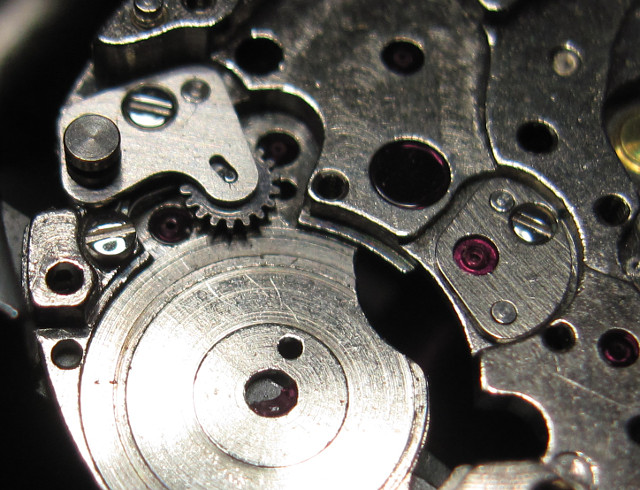

In the detail view, you can see the spring, which puts the clutch wheel in its active position.

The selfwinding mechanism consists of a floating(between two large ruby plates) pinion, two changer wheels and a transmission wheel. Depending of the direction of the axle-beared oscillating weight, the pinion engages with either the left of the right changer wheel and ensure, that the transmission wheel always turns in the same direction. It also prevents free spinning the mainspring barrel, because the Buren 04 doesn’t have a conventional click mechanism.

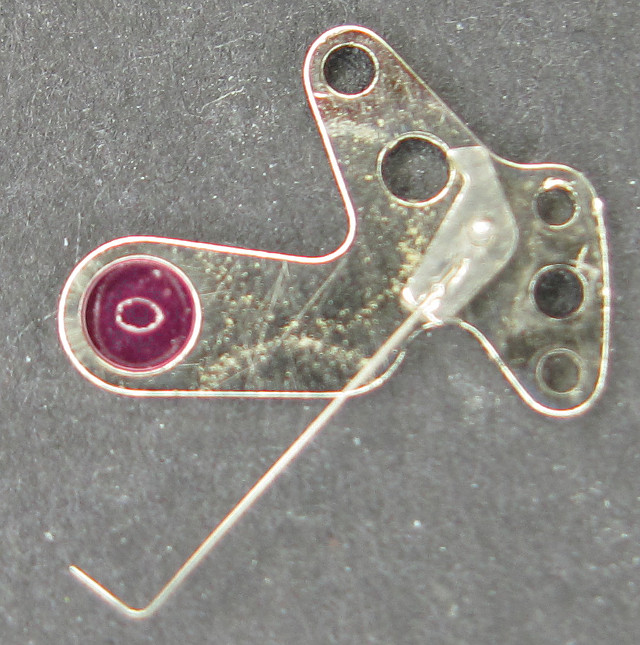

The ratchet ensures the switching of the pinion, since the exchange wheel is blocked by a click, when turned in the wrong direction.

The ratchet is ruby-beared. The following image shows, how it interconnects with the right changing wheel:

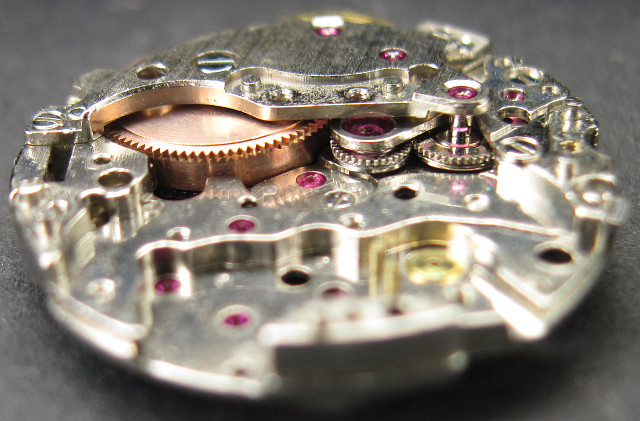

The oscillating weight (which is missing in the specimen shown here) is mounted with a double screws tap on the top side of the selfwinding bridge, and its gears connect with the ruby-beared floating pinion:

Not quite so spectacular, but still more interesing as in other movements, is the view of the raw dial side:

On the yet empty dial side, you can see, that for space reasons, only a rocking bar winding system is used. The friction spring is described a little bit later.

At 3 o’clock, you see the cluth drive of the second whee, whose lower side engages with the mainspring barrel. Its upper side drives a changer wheel, which drives the hands.

At 5 o’clock, you see the changer wheel, which is held in position by a friction spring. Without that spring, it would be much more difficult to exactly set the time, since each gear has got a little free run, and they’re adding to each other.

In the final state, you see, that the clutch drive is of course also ruby-beared.

The mainspring barrel bearing at 1 o’clock is also ruby-beared, but on the specimen here, it is broken and only a few parts of it remain.

In the lab

Technical data

| Manufacturer: | Buren |

| Caliber: | 04 |

| Size: | 7 3/4''' (measured: 17,1mm) |

| A/h: | 21600 |

| lift angle: | 48° |

| Number of jewels: | 30 |

| Escapement: | Pallet lever |

| Balance types: | Glucydur anular balance |

| Shock protection(s): | KIF Ultraflex |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | rocking bar winding system |

| Setting lever spring: | 1 hole |

| Features: |

|

| References: | Flume: K3 158 |

| Mentioning in literature (years): | 1968 |

| Inventory number: | 17006 |