Description

The 11 1/2 ligne chinese selfwinding movement, which looks pretty crude, cannot be identified, since it carries no caliber number at all.

As on the caliber R16-1, the base construction of the gear train bases on the Shanghai SB1.

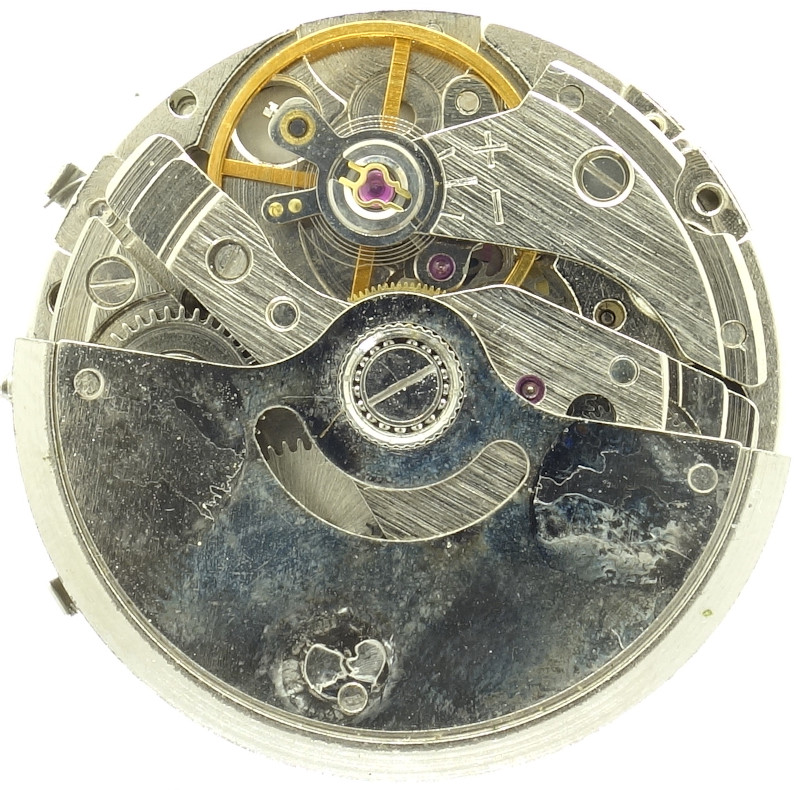

The base plate looks, especially around the escape wheel (at position 1 o’clock) very crude, but at least all important bearings contain rubies.

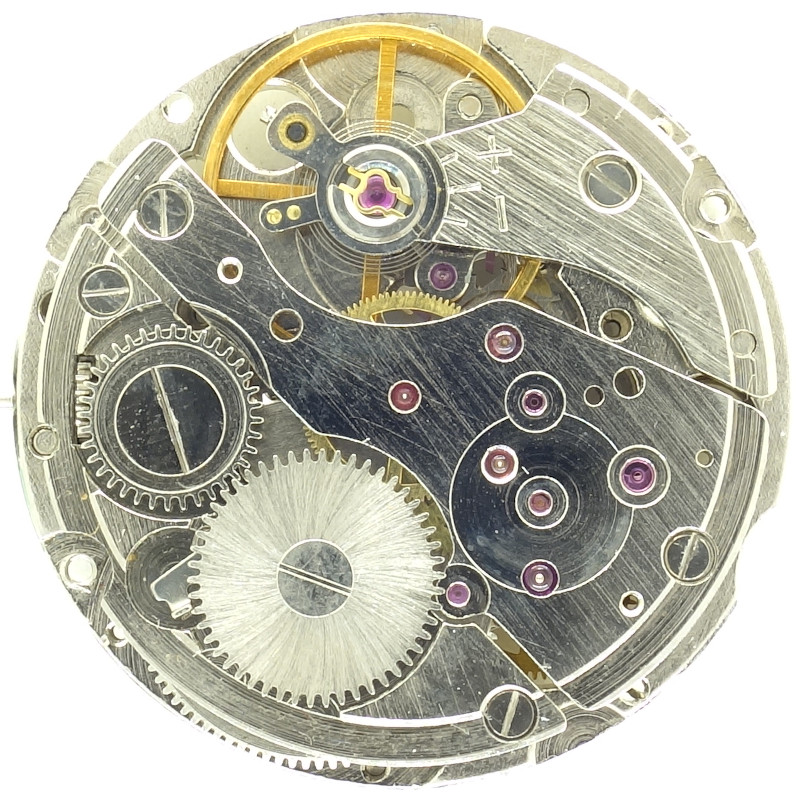

Unlike the very simple china movement, here a gear train with indirectly driven minute wheel is used.

The mainspring barrel drives the large driving wheel, followed by third wheel (which drives the minute wheel on the dial side), center seconds wheel and escape wheel.

The center seconds wheel is only beared on the movement side in a ruby bearing; on the dial side, it runs in a brass tube.

The golden toned, four leg anular balance beats with 21600 A/h and can be adjusted with the hairspring key only.

It is beared in two not further identifiable chinese shock protections, which are even two different ones.

The ratches uses a very simple, but surprisingly efficient construction. It consists of only one part, a cirular spring with a mounted click.

An odd detail is the moveable crown wheel, which can disengage with the ratchet wheel. The reason is unknown, because the winding stem also uses the traditional breguet clutch to disengage the crown.

The crude execution of the movement is visible everywhere. There’s no polishing of the plates and no decoration at all.

The selfwinding mechanism is well made: The ball beared oscillating weight drives the first change wheel, which, with its outer teeth, engages with the second change wheel. Both of them use a kind of “Gyroton” ratchet, which runs freely in one direction and engages in the other direction. Because of this, the oscillating weight winds in both directions.

When you manually wind the movement, it can happen, that the oscillating weight starts to spin in high speed. This is a sign of bad quality.

The amount of steel balls for the ball bearing of the oscillating weight is impressive: No less than seventeen of them are used!

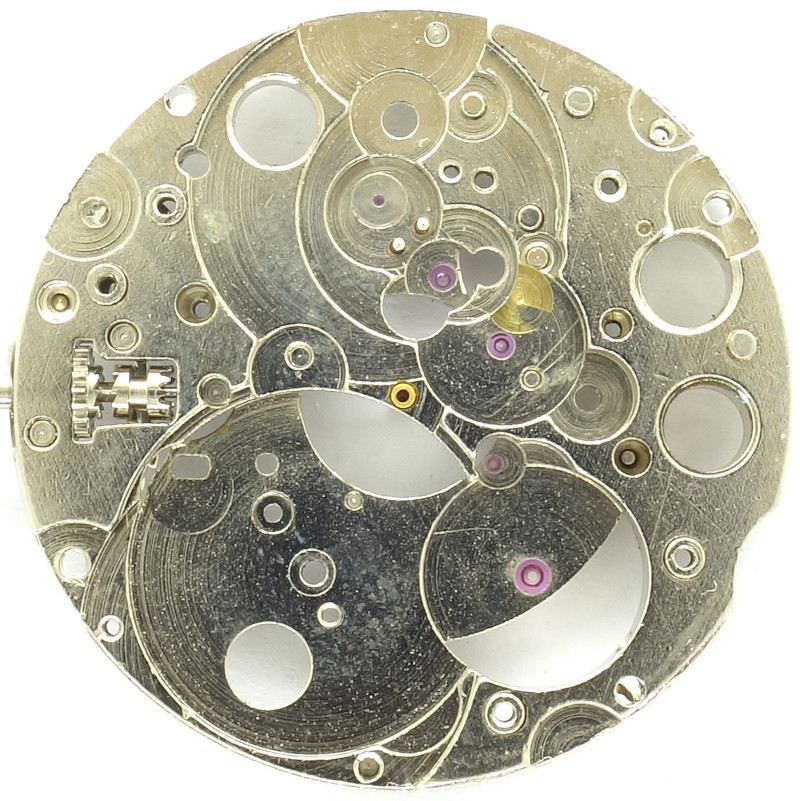

On the empty dial side, you immideatly see, that the balance bearing looks different than on the movement side. The shock protecting spring reminds a bit of that of an Incabloc, but only from distance.

At 8 o’clock, you can see the gears of the third wheel, which engage on the dial side minute wheel, which contains a slipping clutch for the cannon pinion.

On the right, there’s unsurprisingly, the yoke winding system.

The calendar mechanism is constructed in an odd way: Two gears with more or less long or partially missing teeth and a spring ensure, that the date advances slowly between 23:20 and midnight and can be corrected by turning the hand back and forth.

Additionally, at position 4 o’clock, there’s a flying beared wheel for a date quickset mechanism, which is active in the middle crown position.

Unfortunately, it is so badly executed, that it engages only randomly.

A speciality is the gear at 5 o’clock: It is used to drive the 24hr hands and disc, which are mounted on the floor above (see below in the article).

On the covered calendar mechanism, there are multiple windows for the date ring (and for differently printed date rings); on the “correct” one, there’s a tiny magnifying glass inserted.

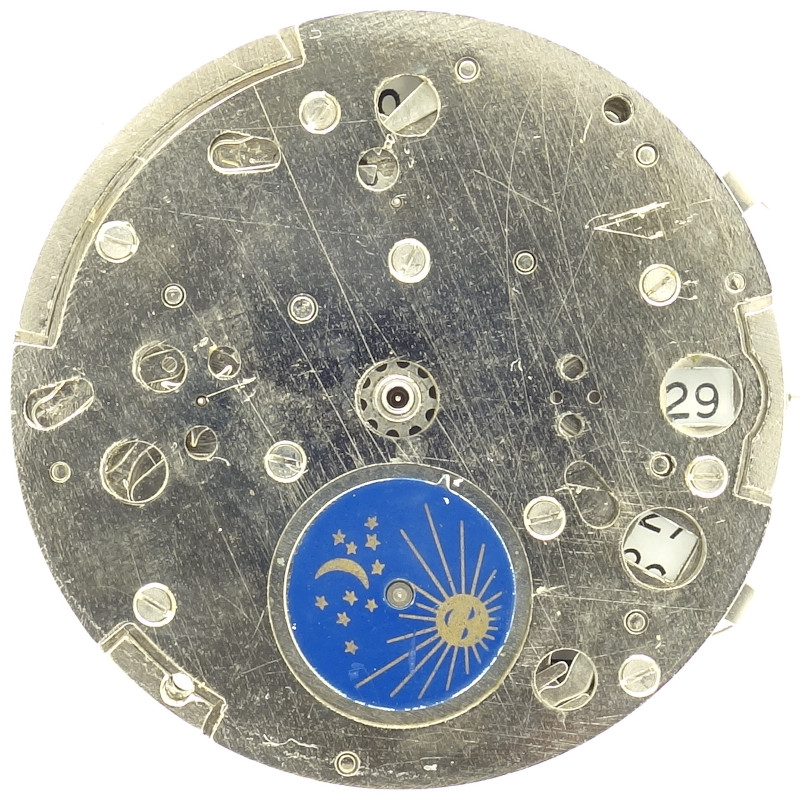

The 24hr indication has got two functions at the same time: First a day/night disc, which should remind of a moon phase indication, and second a hand, mounted at the axle of this disc.

The disc is driven on its lower side by the tiny wheel at 5 o’clock, described above.

The calendar mechanisms and correctors are very fragile:

On the left, there’s an weekday indication with a pointer, driven

by the hour wheel and a switching wheel with one prolonged tooth.

The correcting lever is located at 4 o’clock and needs to be redirected

accordingly.

At position 12 o’clock, there’s a month indication with a pointer. This one only works manually with the pusher at 2 o’clock.

What you cannot see here, are the springs, which reset the pushers.

If you cover the calendar complication, you can see the dial side of this movement is all her non present beauty.

And as raw, as it looks, as raw are the functions: The two pushers at 2 and 4 o’clock are resetted by springs, which are executed so badly, that they slip out of position and render the pushers useless!

This movement is probably an older and no longer produced one and because of this, it cannot be identified any mre.

As bizarre as some functions are made, as bad is their implementation and so, the user won’t be happy for a long time. But for showing this movement in the archive, it is ok nevertheless.

In the lab

This movement came without case into the archiv. On the oscillating weight, there was a label with a fake brand name, which of course was removed.

During a simple revision, the movement showed, how fragile the whole construction is: While the base movement started reliable working again, the calendar indications only function randomly.

Timegrapher result

The rates of this loose movement with unknown history are quite OK:| horizontal positions | |||

|---|---|---|---|

| dial up | +30 s/d | 250° | 0.9ms |

| dial down | -10 s/d | 260° | 0.7ms |

| vertical positions | |||

| crown right (12 up) | -37 s/d | 236° | 1.8ms |

| crown up (3 up) | -30 s/d | 229° | 1.2ms |

| crown left (6 up) | -7 s/d | 235° | 1.1ms |

| crown down (9 up) | +2 s/d | 237° | 0.6ms |

Technical data

| Manufacturer: | China |

| Caliber: | ? |

| Size: | 11 1/2''' (measured: 26,0mm) |

| A/h: | 21600 |

| Number of jewels: | 35 |

| Escapement: | Pallet lever |

| Balance types: | Nickel anular balance (four legs) |

| Shock protection(s): | China (different types) |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 3 holes |

| Features: |

|

| Inventory number: | 20049 |