Description

For a little more than 100 years, Cyma produced their own high quality movement, among them a small number of selfwindig calibers.

The Cyma 480 was fur sure their best and last inhouse selfwinding movement, which marked the summit of the Cyma constructions.

This movement was so good, that even Longines used it and gave it their own caliber number Longines 380.

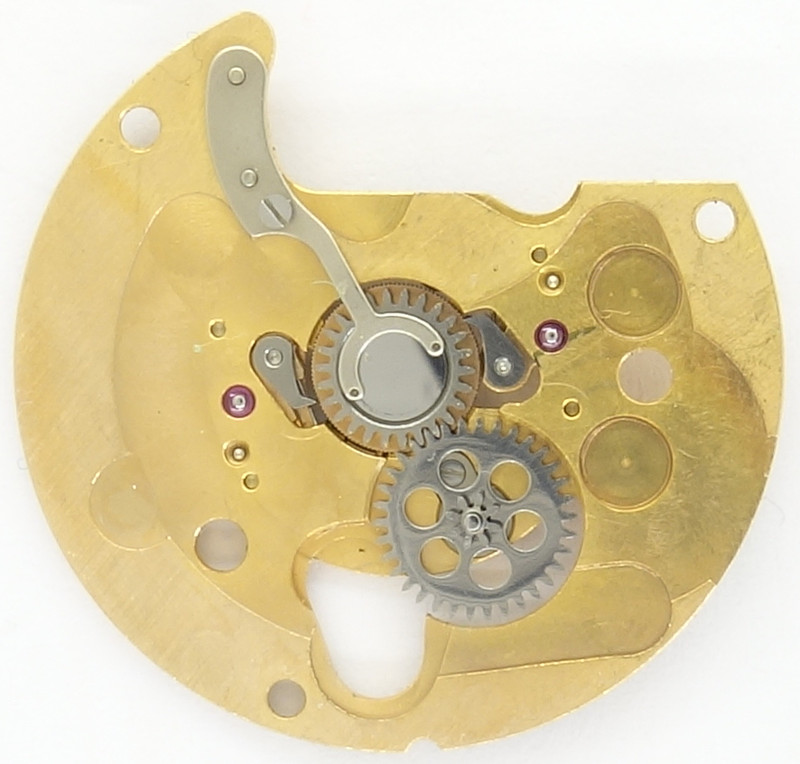

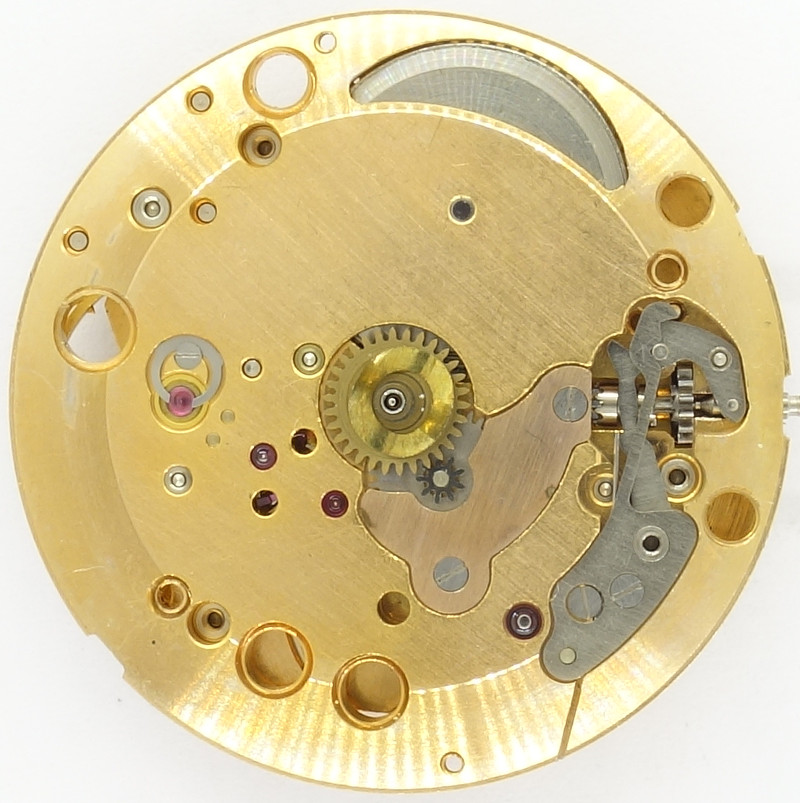

On the golden toned base plate, you can immideatly notice two details: First, the large movement with a diameter of 12 1/2 lignes has got a really large mainspring barrel and second, the gear train is really unusually constructed, to be seen on the far outside bearing at 7:30 o’clock and the ruby axle ar 8 o’clock towards the middle of the plate.

The minute wheel bridgt has got a bearing jewel for the cannon pinion and a recess for the transmission wheel described hereinafter:

Since the cannon pinion has got only a small sprocket and no further reduction gear, the Cyma 480 uses a transmission wheel to the third wheel. This transmission wheel is a simple flat wheel, which is beared on a ruby(!) axle, which is at the same time the bearing ruby for the fourth wheel.

The vertical bearing of the transmission wheel happens with the minute wheel bridge.

Under the gear train bridge, escape wheel, fourth and third wheel are beared.

You can also see the prepration for bearing the decentral seconds wheel, which is used e.g. on the Cyma 481, which has got a decentral seconds indication instead of the center seconds hand.

To sum it up, the really unusual gear train on the Cyma 480 is like that:

The mainspring barrel drives the cannon pinion, followed by a transmission wheel, the third wheel (far ourside), the fourth wheel, the directly driven center seconds wheel and the steel escape wheel.

On the side view, you can see, how the fourth wheel uses the ruby axls as bearing.

The regulator of this extraordinary movement is a very large, golden colored Glucydur screw balance, which is beared in an inhouse Cymaflex-I shock protection.

Its low beating frequency of 18000 A/h is adjusted with a long regulator arm.

Below the gear train bridge, seconds wheel and mainspring barrel are beared - a pretty unusual and rare combination.

When the oscillating weight is driving power, a rocking bar next to the crown is detaching the manual winding system.

On the inner side of the selfwinding module, which is attached with three screws, two spring loaded pawls ensure, that the winding only happens in one direction. The two pawl modules are described next:

The selfwinding system is implemented as an excenter, which engages with two pawl modules into the excenter of the oscillating weight. The two pawl modules consist of a ruby beared roller and a spring loaded pawl.

There’s only one more reduction wheel on the way to the crown wheel.

The two pawl modules are moveably beared to engage or disengage with the center winding wheel.

As you can see well, both pawl modules interfere with their arms and can so be put in their optimal positions.

On the inner side of the axle-beared (in a ruby bearing) oscillating weight, there’s the excenter.

As complex the base caliber and the selfwinding module are, as simple is this movement on the dial side.

Of course, the Cyma 480 uses a yoke winding system, and on its outer side, it is slightly slanted to reduce a little height, because in the 1950ies, watches had to be as flat as possible.

Technical data

| Manufacturer: | Cyma |

| Caliber: | 480 |

| Size: | 12 1/2''' (measured: 27,8mm) |

| A/h: | 18000 |

| lift angle: | 53° |

| Number of jewels: | 27 |

| Escapement: | Pallet lever |

| Balance types: | Glucydur screw balance |

| Shock protection(s): | Cymaflex I |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | no |

| Adjust mechanism: | Long regulator arm |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 4 holes |

| Features: |

|

| Production period: | 1955 - 19?? |

| References: | Flume: K2 - |

| Inventory number: | 20004 |