Description

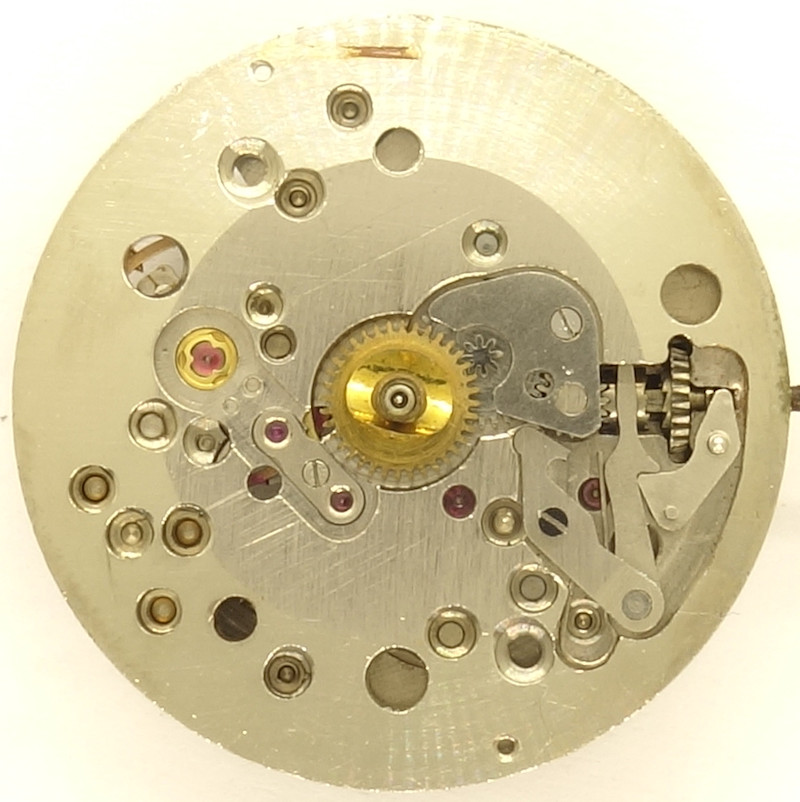

In 1958, the german Förster manufactury released their second caliber series as successor of the series caliber 80.

With a diameter of 11 1/2 lignes, the caliber 90, based on caliber 50, was suitable for gents watches.

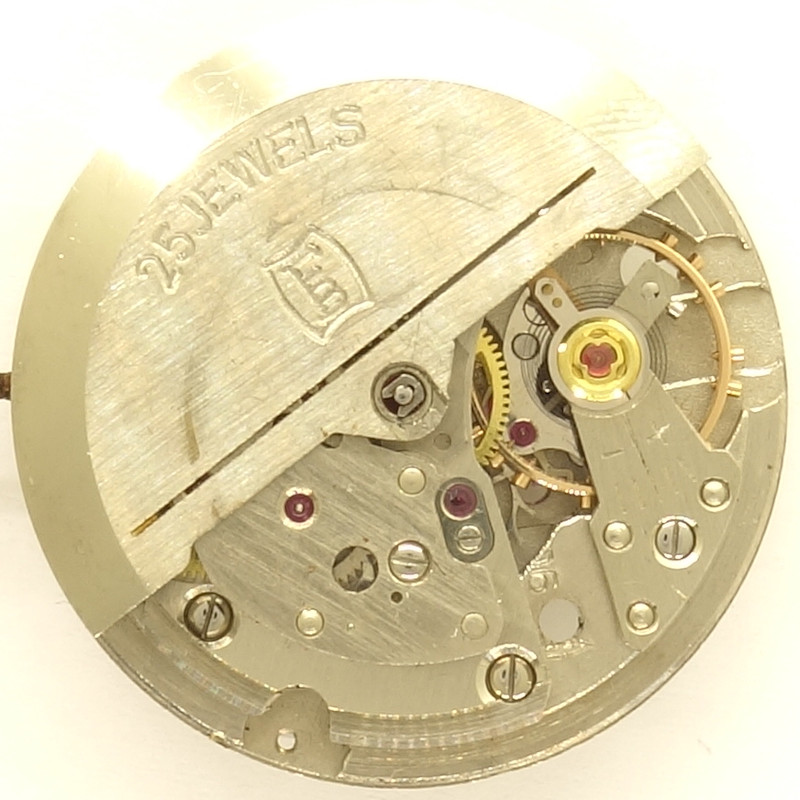

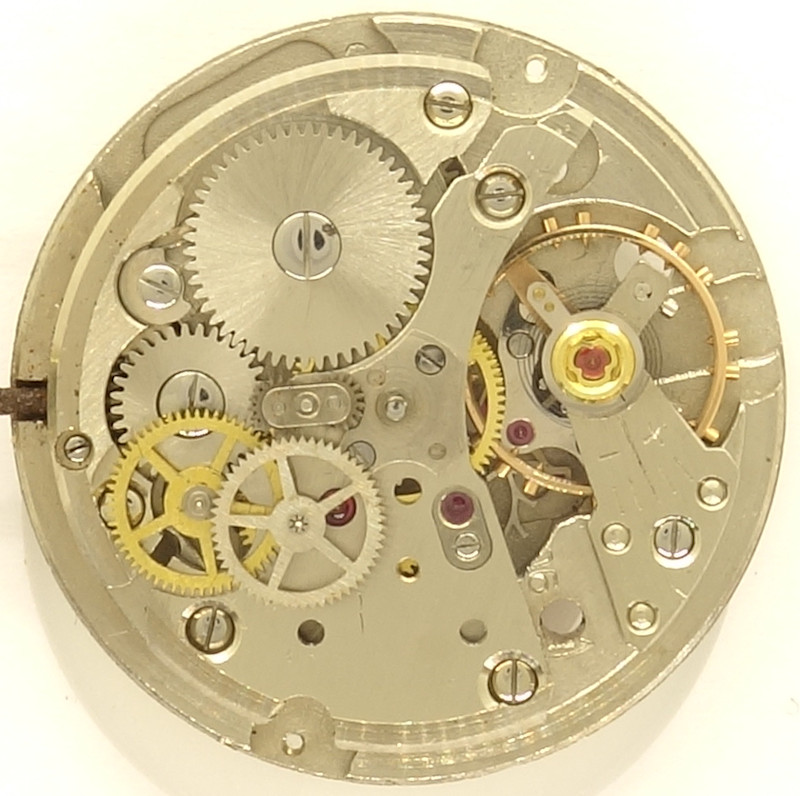

Of course, all important bearings contained rubies, and you see at position 8:30 the additional ruby bearing, in which the Breguet clutch wheel for the automatic mechanism will be beared.

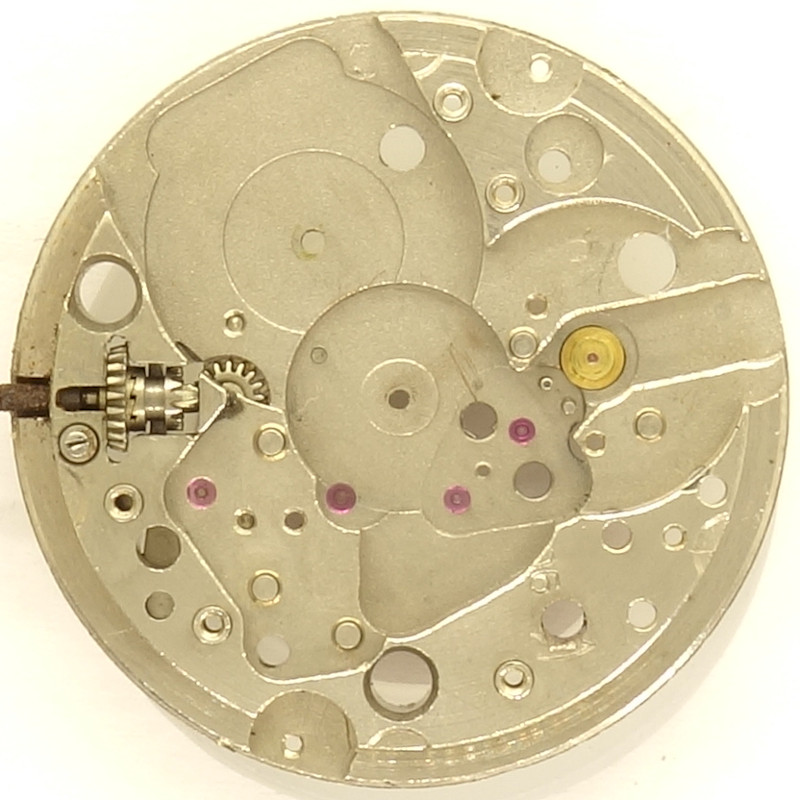

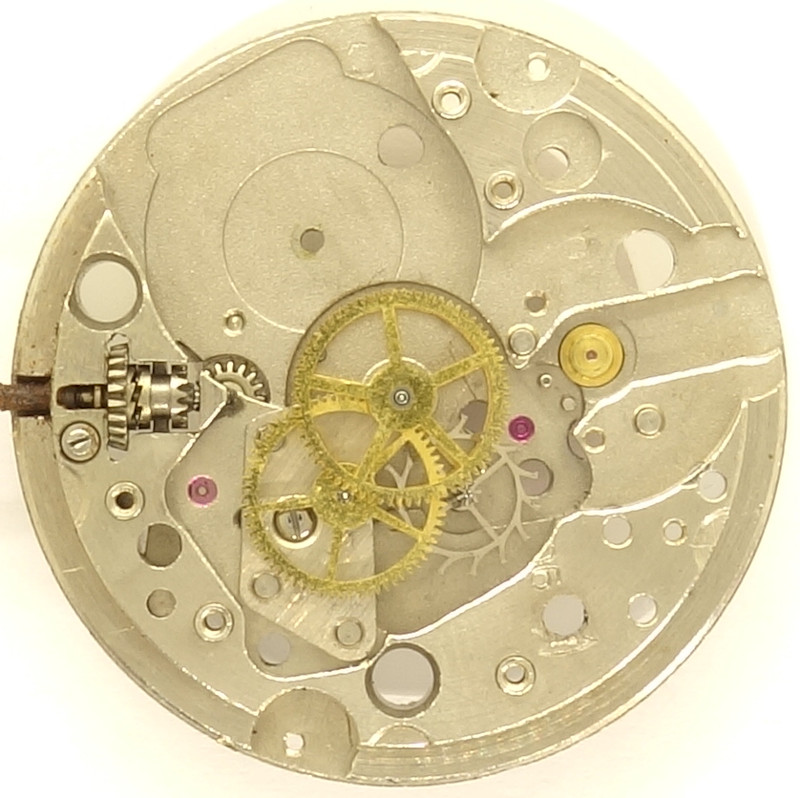

As a classical fifties construction, the Förster 90 uses a directly driven center minute wheel.

The remaining parts of the gear train are conventionally constructed, too: The minute wheel is followed by third wheel, directly driven center seconds wheel and finally the steel escape wheel.

Of course, a swiss pallet lever escapement is used, which is regulated by a slowly (18000 A/h) beating, red-golden toned screw balance.

This balance wheel is visually very much appealing and is beared in two KIF shock protections.

It’s bit sad, that the effective length of the hairspring can be adjusted on the hairspring key only, and not with the help of a long regulator arm.

The selfwinding gear train is directly mounted onto the gear train bridge. You can already see the neccessiary jewels and holes for the mounting.

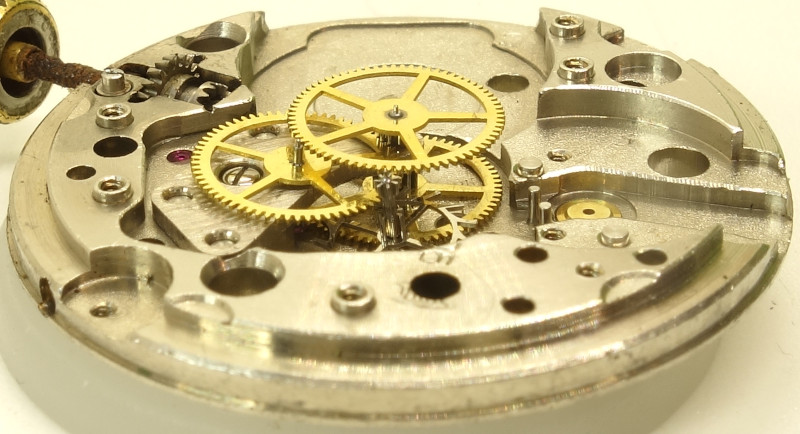

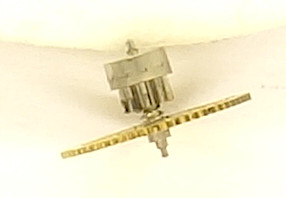

The Förster 90 uses a rocking bar switcher for automatic winding. Depending on the direction of rotation of the rotor, either the first wheel or the second (reverser) wheel engages with the first reduction wheel.

Since the first reduction wheel with the help of a pawl can only rotate in one direction, it is ensured that the second reduction wheel also rotates in the same direction and turns the crown wheel only in the way to wind the watch.

To disengage the selfwinding mechanismus, when the movement is manually wound, the reduction wheel, which engages with the crown wheel, contains a Breguet clutch for this function. On manual wind, no power is transmitted to the selfwinding mechanism.

The selfwinding gear train bridge bears the rocking bear and the two reduction wheels and additionally a ratchet, which prevents, that the first reduction wheel turns backwards.

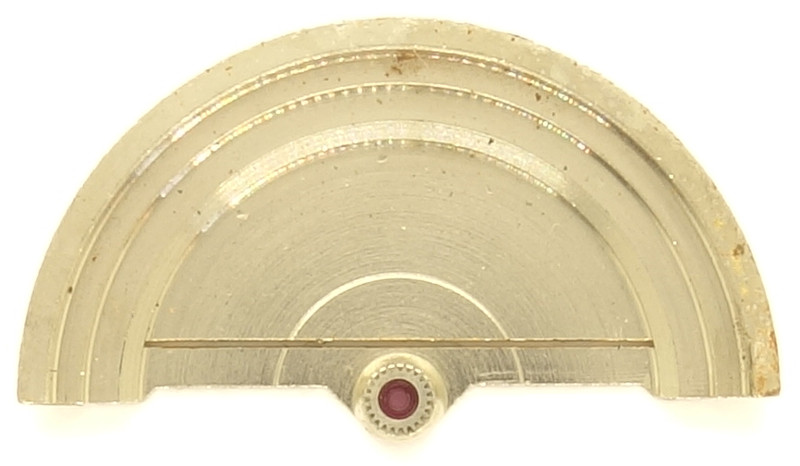

The oscillating weight is axle-beared on this movement.

To reduce abrasion on the rotor axis and thus minimize the radial runout of the oscillating weight, its bearing contains a ruby.

The slot in the rotor is probably used to reduce the impact of shocks onto the axle.

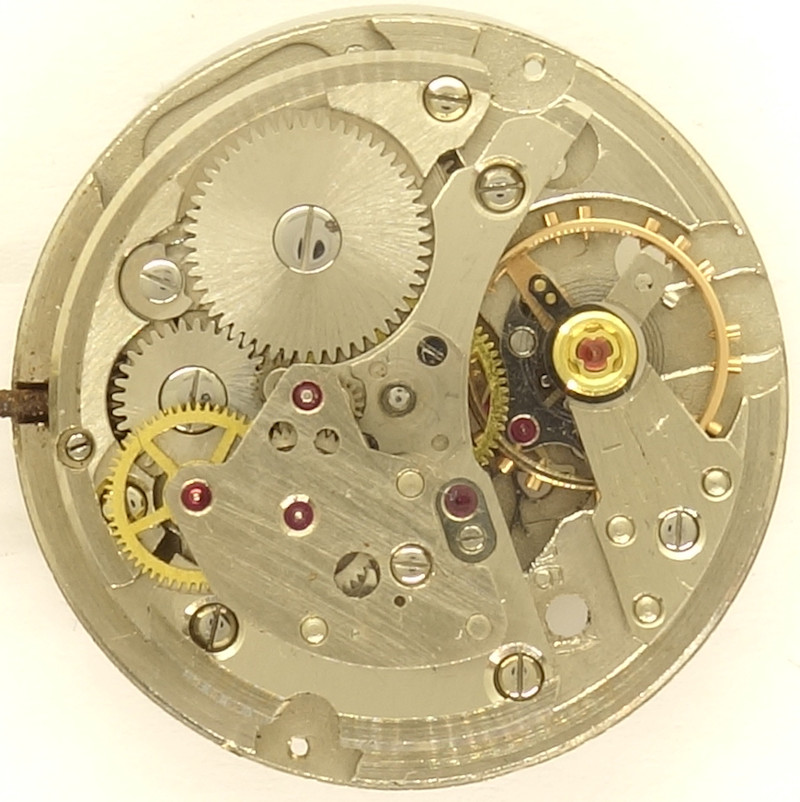

On the dial side you can see the modern yoke winding mechanism (here with broken setting lever spring), the no less modern KIF shock protection and the two cap jewels for the lever bearing (rather meaningless, since this runs oil-free) and the escapement wheel bearing (useful, since the escapement wheel is oil-beared).

Technical data

| Manufacturer: | Förster |

| Caliber: | 90 |

| Caliber base: | Förster 50 |

| Size: | 11 1/2''' (measured: 25,6mm) |

| A/h: | 18000 |

| Number of jewels: | 25 |

| Escapement: | Pallet lever |

| Balance types: | monometallic screw balance (two legs) |

| Shock protection(s): | KIF Protechoc |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | no |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 3 holes |

| Features: |

|

| References: | Feilner: 67 6418 Flume: K2 (1962) 72 |

| Inventory number: | 22008 |