Description

Since the 1960ies, Timex is successful with simply constructed selfwindig movements and can offer them to almost unbeatble prices. The downside of Timex movement is, that they don’t contain ruby bearings and just offer a pin lever escapement, so their precision and lifetime expectancy is not really great.

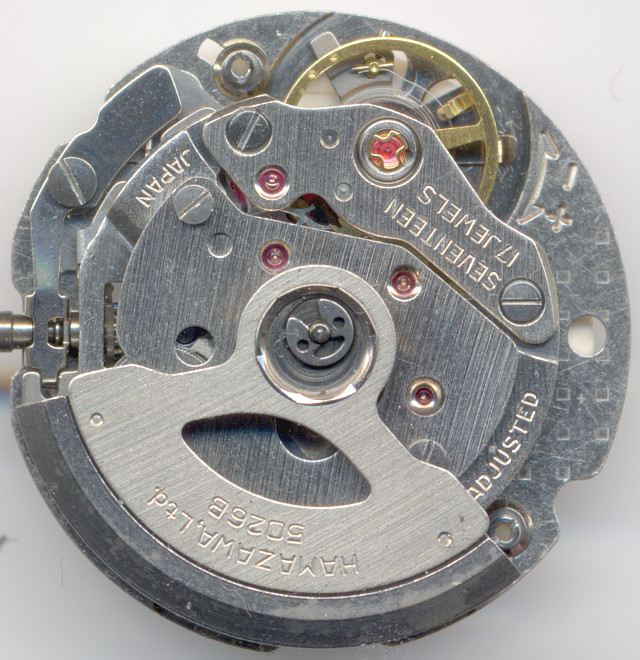

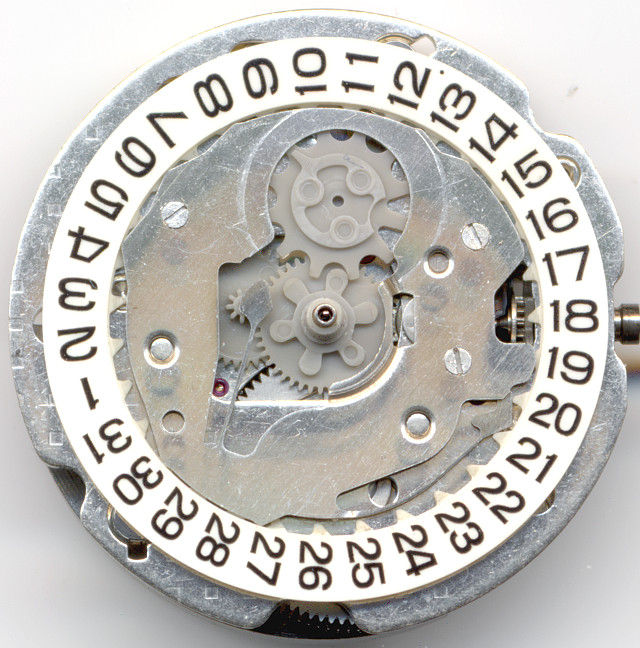

Maybe, ten years later, the japanese company Hamazawa thought, they could to the same, but in better quality, and released the movement family 5000, of which the probably last movement is the Hamazawa 5026B shown here.

If and yet how far Seiko was involved is unknown, but there are some details, which support that theory.

The balance is, just like on Timex movements, fix attached to the base plate, but at least here’s a moveable hairspring stud which helps to minimize the beat error of the contemporarily semi-fast beating balance with 21600 A/h:

This details is not available on Timex movements, neither the simple regulator arm, which here consists of metal flat. This regulator arm allows more precise and less risky deviation adjustmenst:

The setting mechanism is riveted to the base plate (or at least pinned in a way, so that it can not be removed without breaking), it is designed ingeniously and handles three positions: Winding, rapid date adjustment and time setting. Everything is done only with the particular stem-crown and the corresponding wheels, in which the engagement takes place. A setting lever is not necessary, only a simple spring, with which the three locking positions (also part of the stem-crown as rings) to be secured.

But beware of breaking the winding stem… A new production is very sophisticated because of the the fixed gear which is intended for adjusting the time! In the first picture you can see the double gearing of time setting wheel. On the outer side, there’s the engagement to the drive wheel (on top of the mainspring barren), on the the inner side there’s the engagement of the winding stem, note the 45-degree angle of the tooth flanks!

The date adjustment happens through a plastic setting wheel, which is stuck on the winding stem and effective in the second position.

Since this construction lacks a breguet clutch, the decoupling during back winding must be realized differently. For this case, the crown wheel slips out of position. During normal winding, the spring ensures proper engagement into the winding wheel on the mainspring barrel.

The gears and trains remind of a quarz movement because of the almost massive brass gears and also of Timex movements (pillar construction, all under one single bridge).

With a directly driven center second and an indirectly driven minute hand, it is a modern construction. A nice detail is the unusual escapement wheel, which has got five instead of the usual four legs.

Probably due to lack of space, a lateral lever is used. Its geometry and the axle, which is not in the center of gravity have negative influence to its balance, which results in more or less large position errors. A true swiss pallet lever should be completey balanced.

The lever fork engages head on bottom with the finger of the balance. Of course, like on all important bearings, there are ruby bearings, 17 altogether. The balance runs in two Seiko Diashock bearings.

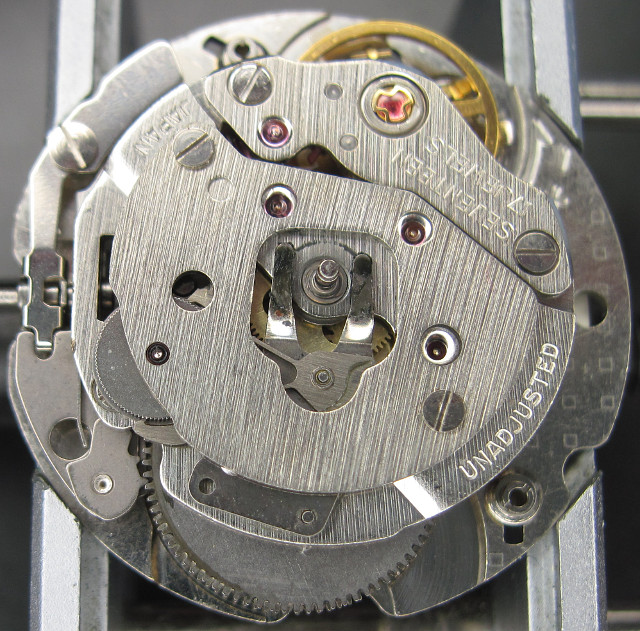

The punched gear bridge, which sits on pillars, allows to assemble the movement without escapement and so to ensure, that it runs perfectly without resistance. Here, the Hamazawa 5026B is much better than Timex movements and even better than its predecessor Hamazawa 5026A, on which lever and balance and beyond the single main bridge.

The selfwinding mechanism partially uses the Magic Lever system of Seiko. Another indication for a cooperation with Seiko. The difference to the Seiko selfwinding mechanism is, that the oscillating weight interferes with a metal fork and not like on Seiko with a gear, which is in conjunction with the ratchet lever.

The excenter changer works in a simple way: The fork, mounted at “6” is moved by the excentric rotating oscillating weight to the left and to the right. On the fork, there’s a ratchet lever, which always rotates the ratchet wheel clockwise. In each direction of the lever, one of the ratchets drives the wheel, while the other one slips through. On manual weinding, both levers slip.

Interestingly, even after many years of use, there’s still no sign of wear on the tips of the ratchet lever!

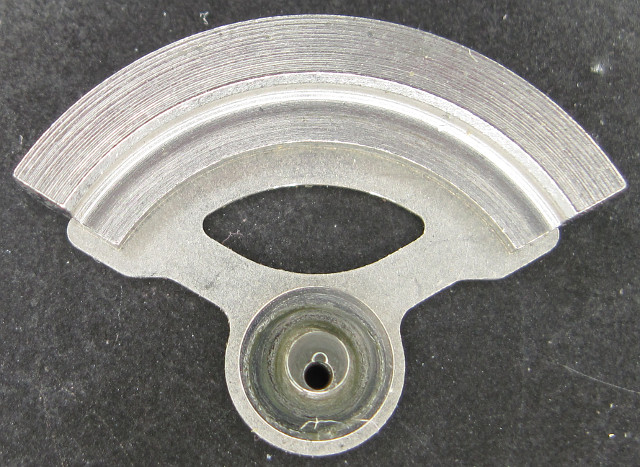

The quadrant rotor has got an excenter bearing, which is ruby-less connected to the fork. More expensive movements (like from IWC, for example) use ruby reels, but functionally-wise the very pragmatic solution of Hamazawa is fully sufficcient.

The oscillating weight is fixed by a snap ring onto its axle, which is riveted to the selfwinding plate. Simple, pragmatic, good.

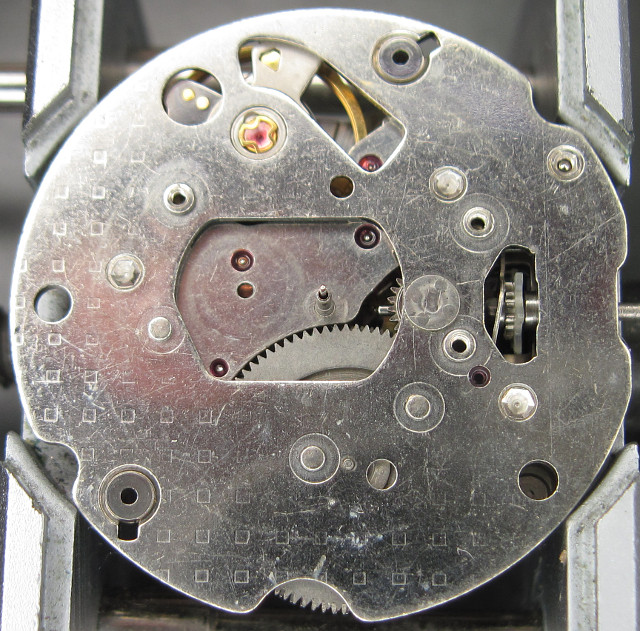

On the dial side, you won’t find any traces of a winding system, only the date correcting wheel. You also see a very simple decoration, consisting of stamped quads.

You also see, that the upper mainspring barrel wheel drives the centered minute wheel. Unlike true Roskopf constructions, we have got here a changing wheel, too, which drives the hour wheel.

The calendar mechanism is pragmatic-simple, better than on Timex movements. It consists of three plastic gears (like on quartz movements), of which the most important part is the switching star at “12”, on which a lengthened finger (at 5’o clock at the wheel) advances the date ring counterclockwise. The switching process runs between 23 and 24 o’clock, and when you turn the time backwards, the finger slips and does not switch back the date.

The smaller inner finger (at 12 o’clock at the wheel) slowly advances the weekday disc by two positions, starting at midnight. Turning back the time sets ot back only one position. That allows to change the language of the weekday indication, here in english and spain.

The cover plate of the calendar mechanism has got two springs, which ensure proper positioning of the date ring and the weekday disc.

This movement is a nice example, how the success of quartz movements influenced design and production of cost efficient, but well equipped mechanical movements. Even when a repair of such a movement is beyond its worth, it is still possible. Later movements, like the Q&Q 2604 are true disposable movements, altough conceptionally they don’t differ that much. And last but not least, you have to remember, that all that disposable movements have the same ancestor, the disposable Timex movements, which influenced them heavily.

In the lab

The movement shown here was quite gummed up. Its case was full of cracks and dents and shows many, many years of heavily use. On the timegrapher, it was not possible get a usable signal on the timegrapher.

After a full service and some days to break in, it showed acceptable rates which are perfectly ok for daily use.

Timegrapher result

| horizontal positions | |||

|---|---|---|---|

| dial up | +29 s/d | 154° | 0.3ms |

| dial down | +38 s/d | 150° | 0.2ms |

| vertical positions | |||

| crown right (12 up) | -43 s/d | 200° | 0.1ms |

| crown up (3 up) | -95 s/d | 188° | 0.2ms |

| crown left (6 up) | -65 s/d | 135° | 0.9ms |

| crown down (9 up) | -87 s/d | 200° | 0.5ms |

Technical data

| Manufacturer: | Hamazawa |

| Caliber: | 5026B |

| Size: | 11 1/2''' (measured: 26mm) |

| A/h: | 21600 |

| Number of jewels: | 17 |

| Escapement: | Pallet lever |

| Shock protection(s): | Diashock (Seiko) |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Long regulator arm |

| Construction type: | pillar construction |

| Winding mechanism: | special winding system |

| Features: |

|