Description

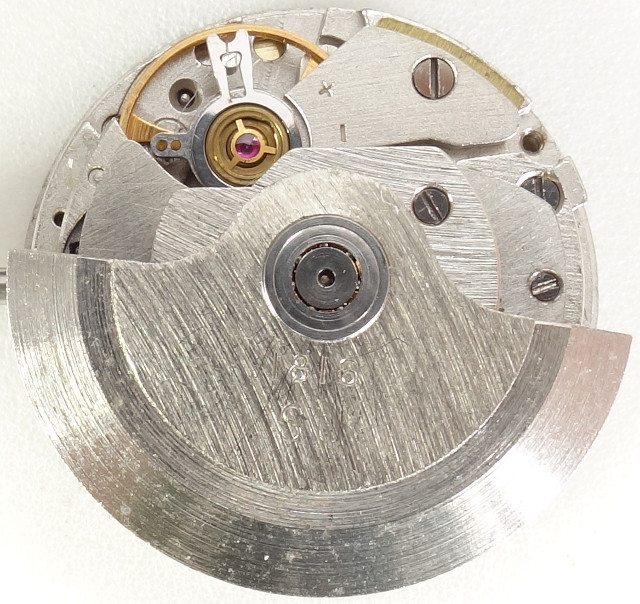

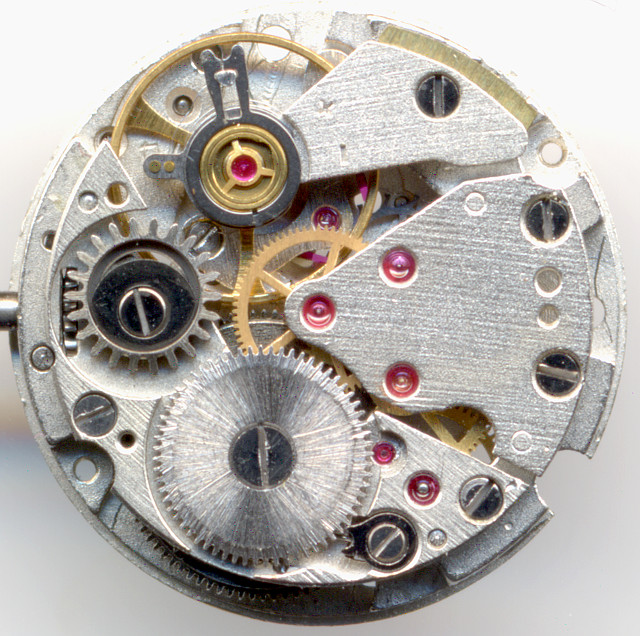

Around the mid 1970ies, the Minsk watch factory Luch released their only selfwinding movement in ladies’ watch size (8 lignes / 18mm diameter). It based on the manual wind caliber 1814 to which a selfwinding module was added.

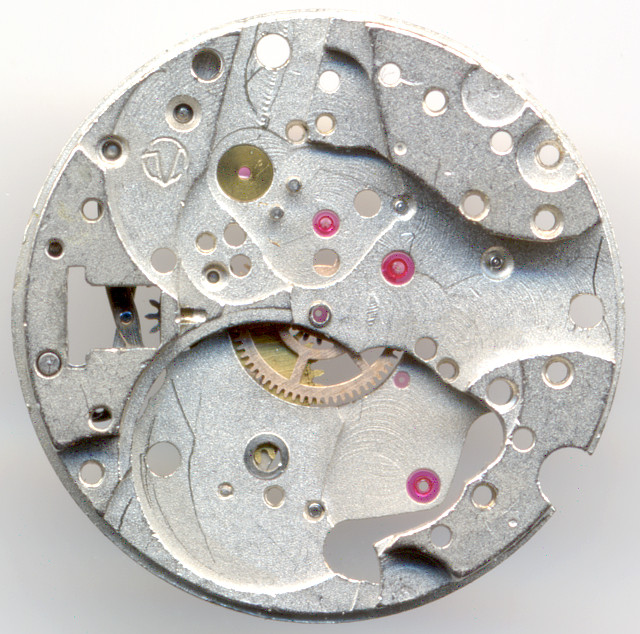

The base plate already reveals, that it has got a very modern construction, since there’s no place for a central minute wheel, the hands are all driven on the movement side indirectly by the third wheel.

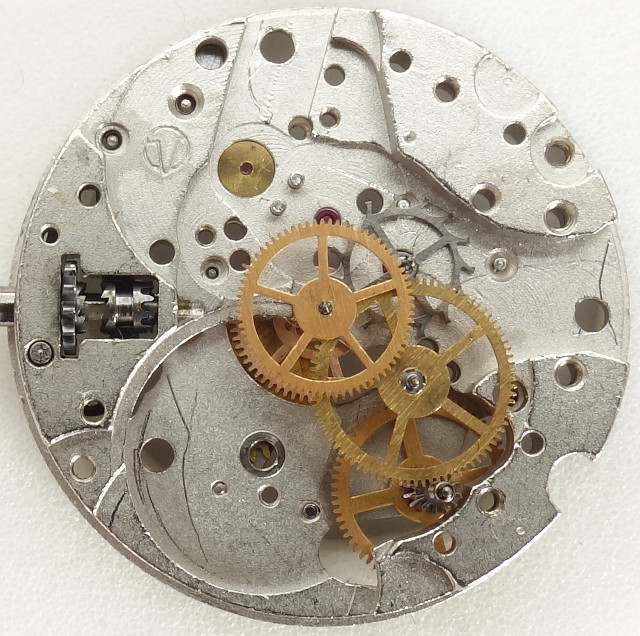

The gear train consists of mainspring barrel, second wheel, third wheel (with clutch), center second wheel and escapement wheel.

With its large wheels, this movement is easy to service.

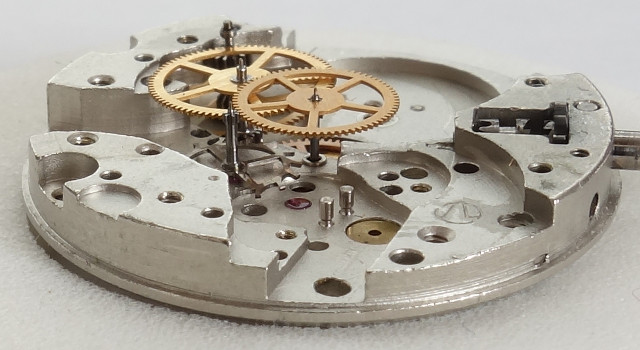

The anular balance is beared in two russian shock protections. It beats rather slowly with 21600 A/h and regulates a pallet lever movement of swiss type.

This gear train became popular due to ETA since the late 1950ies and is used until today.

Since no center minute wheel is used, there’s much more space for the mainspring barrel and the balance, which is very helpful on movements with small diameter to achieve a longer power reserve and better precision.

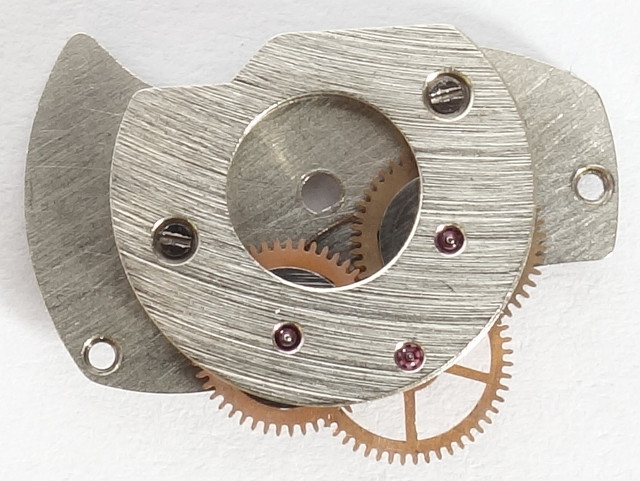

With the removed selfwinding module, you can see the moveable crown wheel, which detaches the crown when its turned backwards. Normally, a breguet clutch is responsible by that function, and it also is available on the Luch 1816!

The selfwinding module is attached with two screws onto the movement and engages at 5:30 o’clock into the ratchet wheel. The bearing is even equipped with a ruby.

The selfwinding mechanism is implemented as a freewheel changer, so the ball-beared oscillating weight is connected to changging gears, which are equipped with a handful of flat inner discs which engage in one direction and decouple in the other direction. This principle was particularly famous for the “gyrotron” movements of Girard-Perregaux, but was also used on Russian movements such as the Vostok 2416.

This mechanism works as mechanical recitifier and ensures, that no matter in which direction the oscillating weight rotates, the driving wheel is always turned in one direction to wind the mainspring.

The axle of the ball-beared oscillating weight is mounted from the lower side of the module, which means, that you cannot release the oscillating weight alone, but you have to detach the whole module.

All gears of the selfwinding module are ruby beared, so the whole movement comes to a total of 21 jewels.

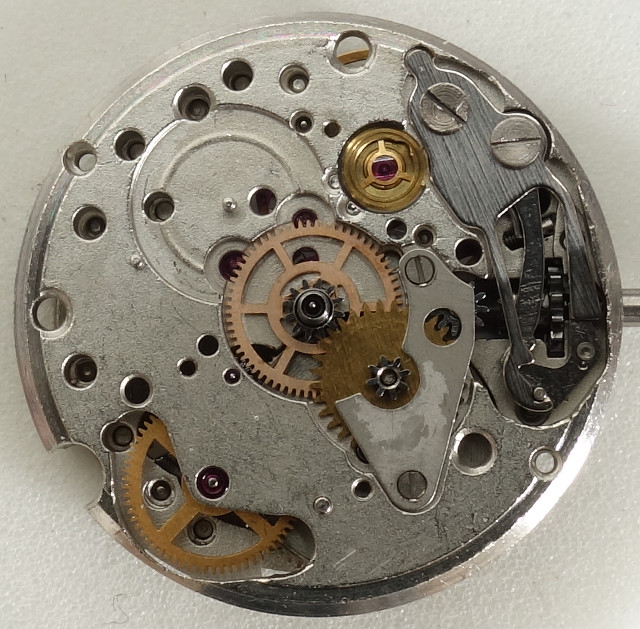

On the empty dial side, you see the minute wheel, which is driven by the third wheel near the center at 7:30 o’clock

Of course this movement has got a yoke winding system.

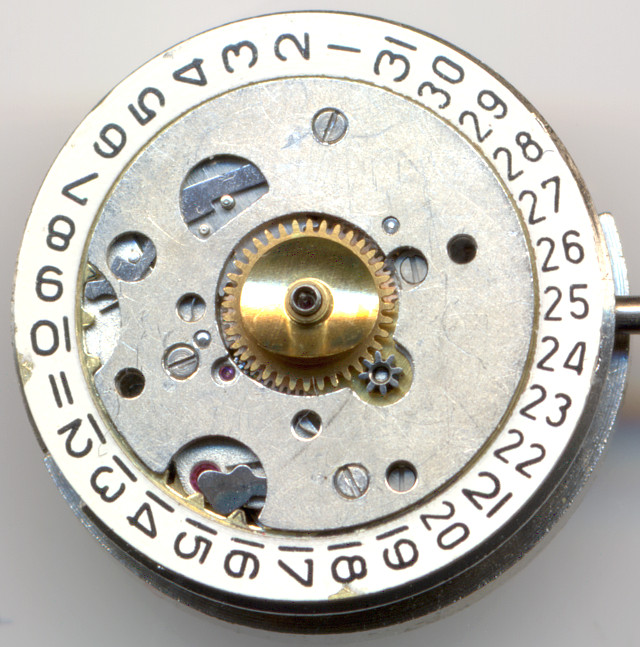

The calendar mechanism is quite unusual and complex. The ratchet wheel at 11 o’clock drives a lever which, with the help of a spring, causes the date to advance instantly at midnight, but can also be corrected halfway (by turning back and forth).

Normally you don’t see the complexity of the calendar mechanism, since it’s hidden behind a securing plate, but be assured, a watchmaker will have some headaches when he has to work on it :)

Technical data

| Manufacturer: | Luch |

| Caliber: | 1816 |

| Caliber base: | Luch 1809 |

| Size: | 8''' (measured: 18mm) |

| Height: | 6,00mm |

| A/h: | 21600 |

| lift angle: | 46° |

| Number of jewels: | 21 |

| Escapement: | Pallet lever |

| Balance types: |

Glucydur anular balance (three legs) |

| Shock protection(s): |

3 arms, russian |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Attachment of setting lever: | plugged |

| Features: |

|

| Mentioning in literature (years): | 1983 |

| Inventory number: | 17028 |