Description

Before Felsa invented the bidirectional selfwinding mechanism in the 1940ies, there were several other selfwinding construction. Often the so-called “Harwood-Type” was used, also known as bumper automatic.

In the early 1940ies, Movado released their first selfwinding movement, a bumper automatic, which had an unusual large diameter of 12 3/4 lignes.

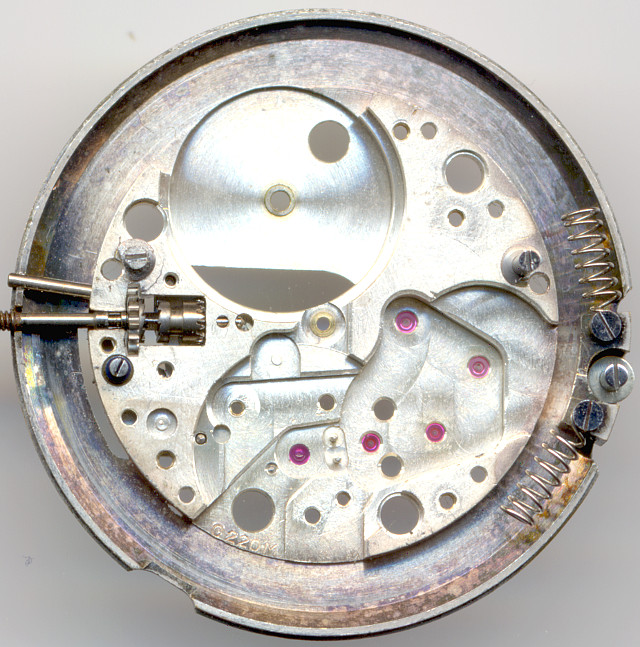

The base plate tells us, that a standard manual wind movement was used as base, but the base plate was enlarged to give place to the bumper and the two buffer springs.

All gears, with the exception of minute wheel and mainspring barrel are ruby-beared.

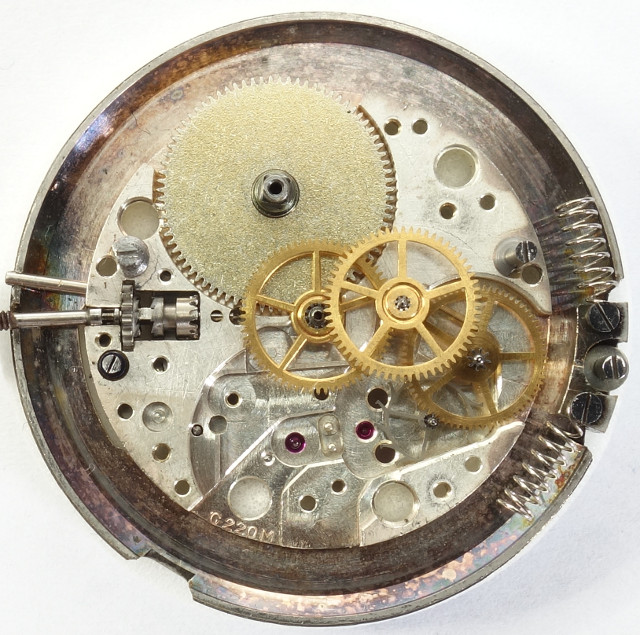

Unlike most other manual wind movements, the gear train works in counter clockwise direction (seen from the movement side). Infact, the gear train uses very few space and allows a large mainspring barrel for an autonomy of 56 hours.

It’s the usual gear train of that epoch with directly driven center minute wheel, third wheel, fourth wheel and escapement wheel.

The center second pinion is driven indirectly by the third wheel. Since that wheel has to be threaded through the gap of the gear bridge, the monting of the four wheels below the gear bridge is very difficult and time consuming like on hardly any other movement.

The center second pinion is beared on both sides and is secured against fluttering by a small leaf spring. Visually and aesthetically a really nice construction.

Just as nice is the golden toned Glucydur screw balance, which beats with 18000 A/h. The only drawback is, that it is not shock protected, which is a bit weird on a movement, which get shocks from the bumper mechanism all the time and is otherwise so well made.

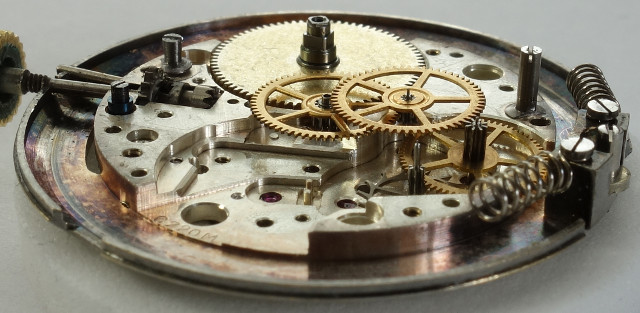

On the mainspring barrel arbour, there’s on top of the ratchet wheel the clutch, consisting of a wheel with a click and an own ratchet. The ratchet is connected to the mainspring barrel arbour, the wheel, which is engaged with the selfwinding mechanism, not. This construction is responsible for detaching the selfwinding mechanism when the movement is wound manually.

The selfwinding mechanism is quite complex with even two pawls. The bumper weight drives the center wheel clockwise and detaches counterclockwise with the help of the two pawls. Then there are three transmission wheels until the clutch wheel is driven.

The selfwinding mechanism builds pretty high. Except for the center wheel, no ruby bearings are used.

The bumper consists of the flywheel mass, a freely moveable gear, a pawl and a spring. This all ensures, that the gear is only driven in one direction and is detached in the other direction. You can easily imagine, why bumper winding systems vanished pretty fast, after the selfwinding mechanisms with oscillating weight became popular.

The decoration on the dial side is a further highlight of that movement. Of course, a yoke winding mechanism is used, too.

In the lab

Timegrapher result

With the exception of the values at 6 o’clock, the timegrapher results are excellent! The high quality of the movement cannot only be seen by the eyes, but also be tracked on the timegrapher.| horizontal positions | |||

|---|---|---|---|

| dial up | -1 s/d | 284° | 0.2ms |

| dial down | +9 s/d | 272° | 0.5ms |

| vertical positions | |||

| crown right (12 up) | -9 s/d | 225° | 0.9ms |

| crown up (3 up) | +11 s/d | 233° | 0.6ms |

| crown left (6 up) | +37 s/d | 222° | 0.1ms |

| crown down (9 up) | -1 s/d | 230° | 0.4ms |

Technical data

| Manufacturer: | Movado |

| Caliber: | 220M |

| Size: | 12 3/4''' (measured: 29,2mm) |

| A/h: | 18000 |

| Number of jewels: | 15 |

| Escapement: | Pallet lever |

| Balance types: | Glucydur screw balance |

| Shock protection(s): | none |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | no |

| Adjust mechanism: | Long regulator arm |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 3 holes |

| Features: |

|

| References: | Flume: 1949 II 103 |

| Inventory number: | 17023 |