Description

The Zenith 1725, which is quite small with a diameter of only 7 3/4 lines possesses a very unusual differential construction, which can hardly be understood by laypeople.

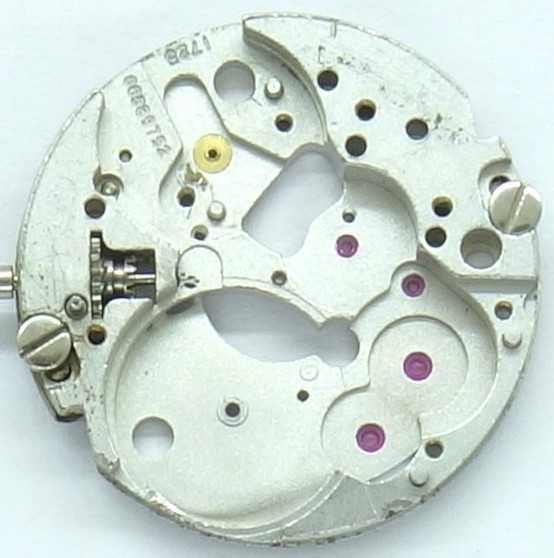

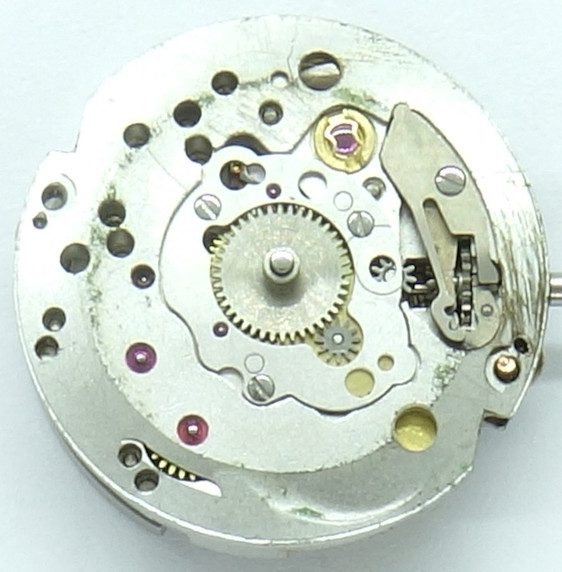

The base plate doesn’t let you guess much; of course are important bearings are equipped with stones.

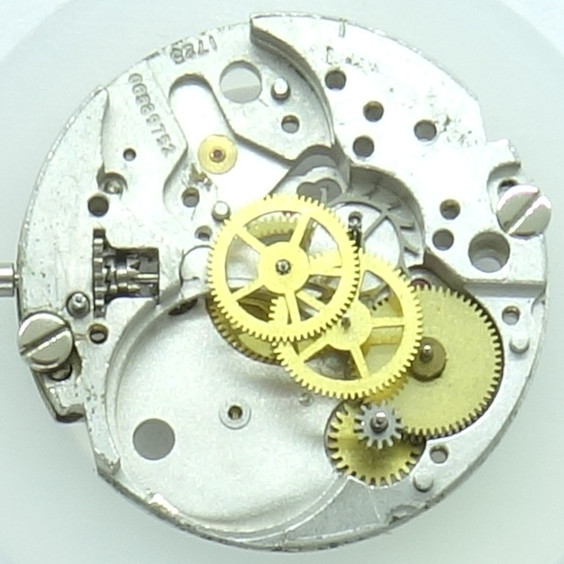

The gear train is unique and hardly understandable for laypeople.

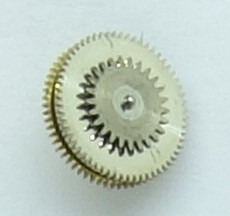

The core is a differential (at 4 o’clock), which is connected to the selfwinding mechanism (upper sprocket), with the gear train (middle sprocket) and with the mainspring barrel (lower sprocket) is engaged.

If the oscillating weight rotates, its rotational energy should be delievered to the gear train. Excess energy is then delivered on the barrel (with the help of a transmission wheel, which acts on the outer ring gear of the spring barrel).

If the oscillating weight does not turn, the energy that has been stored on the mainspring, is delivered to the gear train.

The construction is released under the swiss patent number CH426651A and in Germany as DE000001523868C .

To what extent this construction really makes sense because of the automatic mechanism that produces either (too) much energy for a short time, or none at all for a long time, can only be answered by specialists.

the differential gear is clearly visible on the right, as well, as the construction with its directly driven center second (which is only used on the caliber 1724). The Zenith 1725 only has an hour and minute display indication.

A three-legged, screwless Glucydur balance is used as the regulating organ, which beats at 19,800 vibrations per hour and which is finely adjusted with the help of a toothed regulator.

That two Incabloc shock protections protect the sensitive balance axis is actually a matter of course.

The ratched is located on the inner side of the large gear train bridge, which also houses the mainspring barrel.

The hole at 3 o’clock is for the second selfwinding changeer wheel, which engages with the upper sprocket of the differential gear.

The rotor acts on a sliding drive, which either the left or the right depending on the direction of rotation of the rotor drives change wheel. Because the left change wheel with help a spring-loaded pawl can only turn in one direction this construction acts like a mechanical rectifier, and the right one (upper) change wheel always rotates in the same direction.

The oscillating weight is ball-beared.

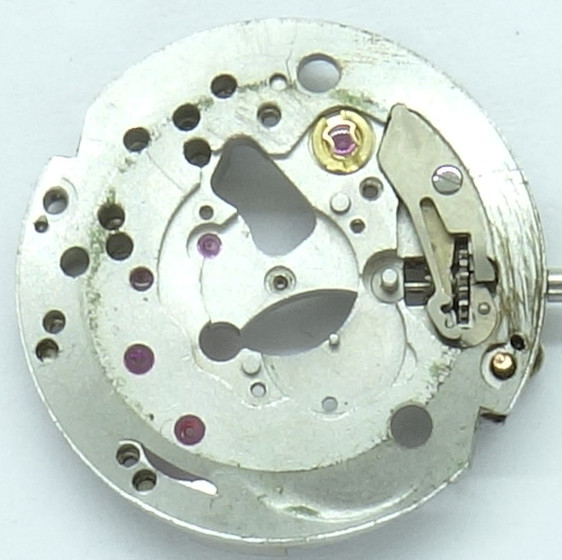

Not much can be seen on the still empty dial side, except that the hands driving works is located on the dial side only.

The third wheel is beared on the dial side under a very flat bridge, which is mounted there. The second bearing of that bridge is for the lever.

When all bridges are mounted and all gears are in their bearings, the complexity of this movement is more or less hidden.

Unfortunately, the specimen shown here was destroyed by a “gold butcher”, who most brutally ripped it out of the case, leaving the base plate bent and the hollow minute wheel shaft was broken. A shame, in this rare and highly interesting work.

Technical data

| Manufacturer: | Zenith |

| Caliber: | 1725 |

| Size: | 7 3/4''' (measured: 17,3mm) |

| Height: | 4,35mm |

| A/h: | 19800 |

| lift angle: | 51° |

| Number of jewels: | 25 |

| Escapement: | Pallet lever |

| Balance types: | Glucydur anular balance (three legs) |

| Shock protection(s): | Incabloc |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | unknown |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 1 hole |

| Features: |

|

| References: | Flume: K3 - |

| Inventory number: | 21044 |