Description

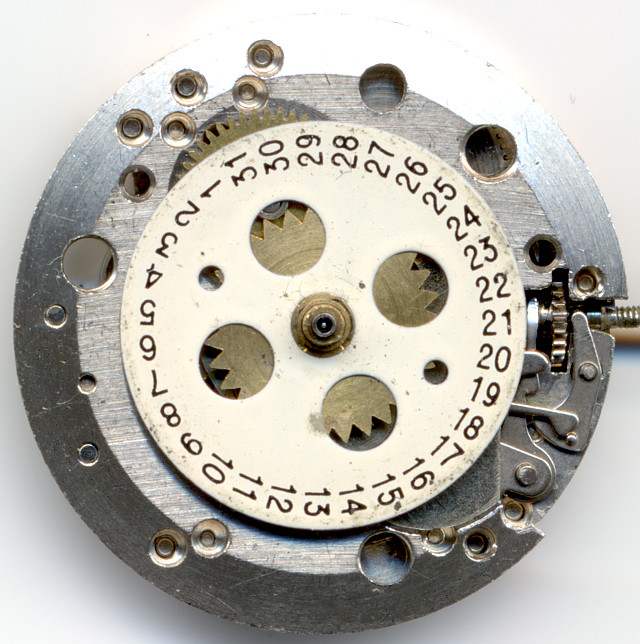

In the early 1960ies, Intex released the caliber series 1057, which consists of simple three-hand manual wound movements up to a selfwinding movement with date indication. They all carried the same caliber number, so Flume (and hence, I, too) decided to add their features to it’s caliber number.

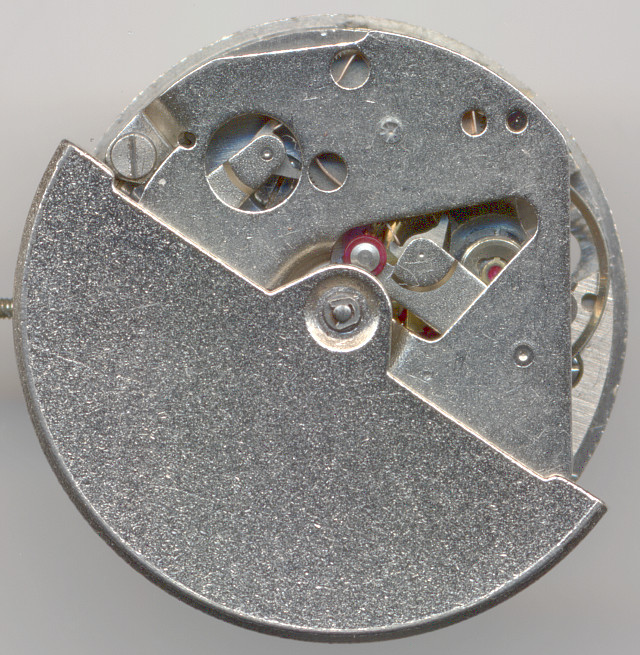

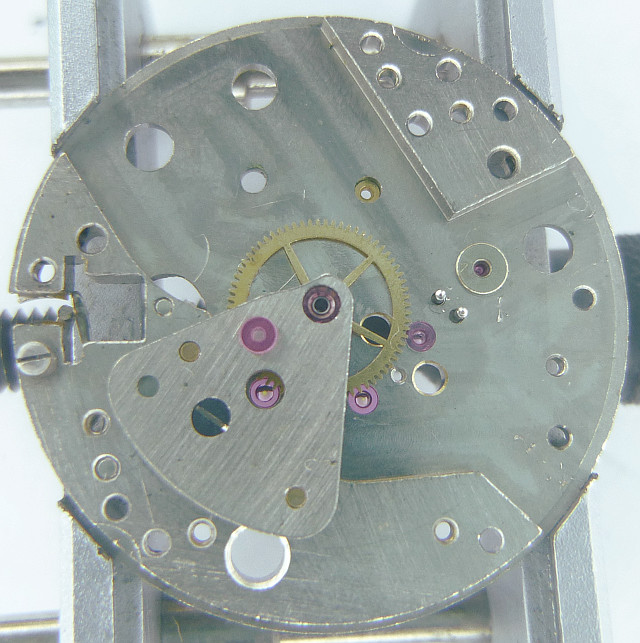

Video on YouTubeThe selfwinding module on top is a very simple, riveted construction, which is described in detail on the AHS 154. This module was also called “Robot-Automatic” and is simply put onto the movement with only two screws.

When the driving wheel of the module finds no space, there’s just a U-shape polished into the winding bridge:

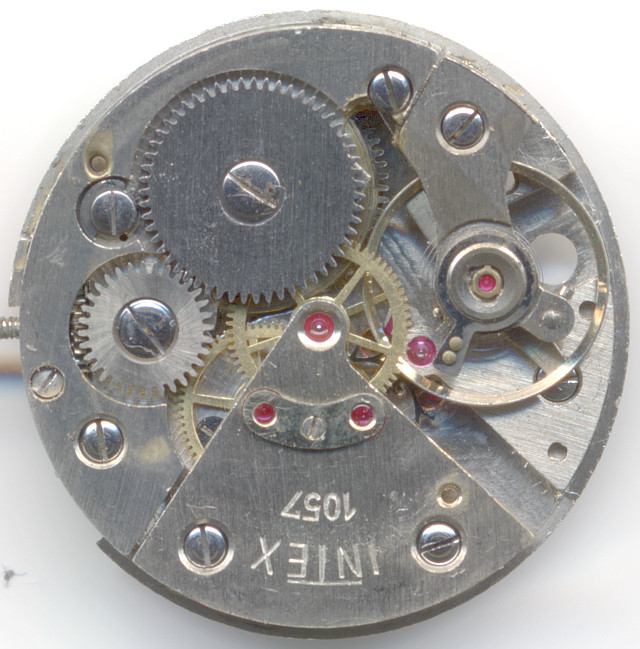

Without selfwindig module, the Intex 1057 is a very normal handwound movement with the small oddity of having lots of disfunctional cap jewels.

The mounting holes for the selfwindig module can be seen at the positions “10 o’clock” and “5 o’clock”; the U-shaped hole for the driving wheel at “12:30 o’clock”.

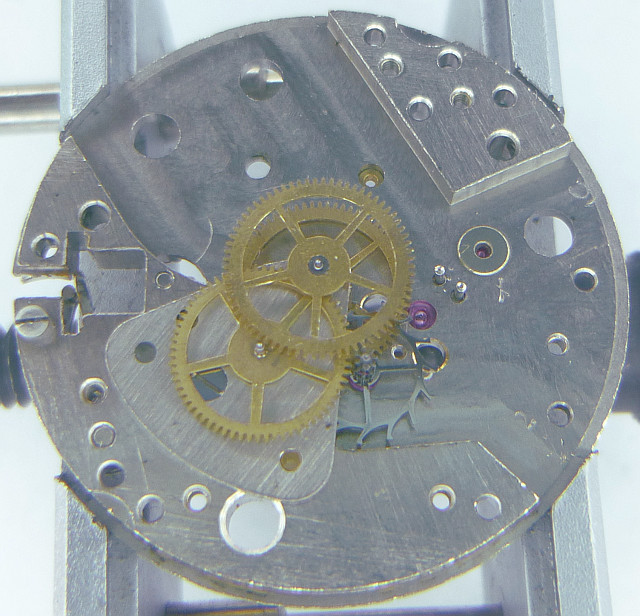

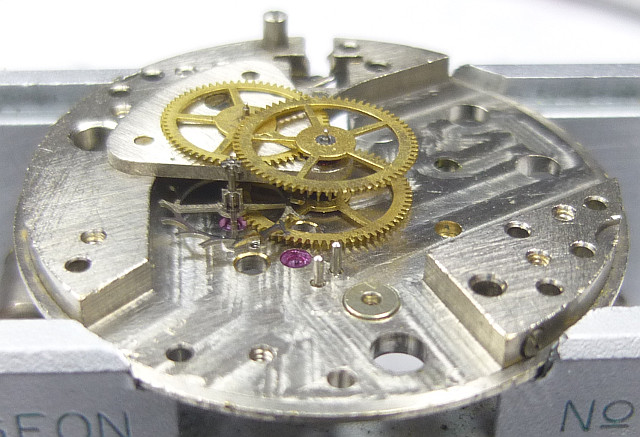

The construction is a contemporary 1960ies construction: The screwless ring balance, secured in a pair or Farr shock protections, beats slowly with 18000 A/h and controls a pallet lever movement with directly driven center second and two-storey gears: On top the center second wheel; on bottom the minute wheel.

The two-storey construction ads some millimeters to the height; together with the rather thick selfwinding module, this movement is really thick!

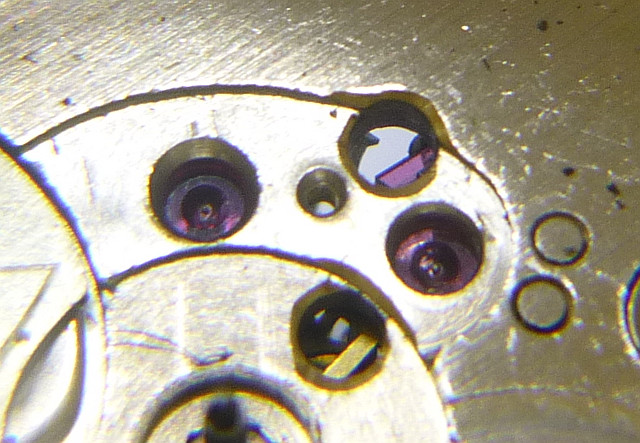

The Intex 1057 AUT SCD CLD has got 25 jewels; one of the sits loose on the minute wheel bridge and is the dial-side bearing for the center second wheel:

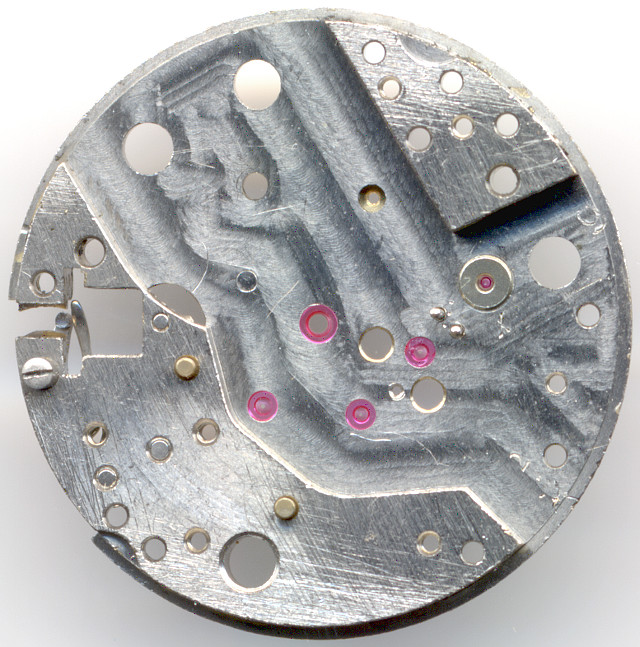

The way, the main plate is “decorated” with a kind of stripe decoractions, but that’s not a decoration, but the paths of a milling cutter.

The cap jewels of this movement are without function, since they just put a cap on the bearing jewels, which reside much deeper. So, the cap jewels cannot secure the oil, but they increase the number of jewels to the same amount as the competitors: 25 jewels.

This movement has got a yoke winding system, below the characteristically shaped housing.

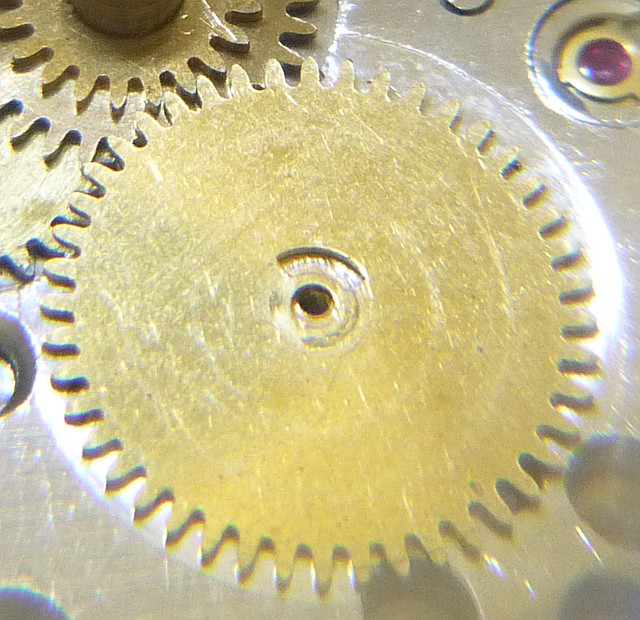

At “11 o’clock” you see the date indication mechanism with its moveable cam, which, together with friction of the date disc and the hour wheel, allows the date to switch safely semi-fast within one hour without any springs!

The picture below shows the date driving wheel with its recess for the moveable cam.

Since this movement uses a date disc and not a ring, the date sits quite on the inner side of the dial and has got very small numbers.

In the lab

The specimen shown here came in heavily used condition with a lose selfwinding module into the lab. There was much contamination because of abraised metal due to the lose module.

The movement was cleaned and olied, except the balance wheel, which was not touched to avoid magnetism of the hairspring.

Additionally, the second hand was missing and the axle was also missing at the top.

Timegrapher result

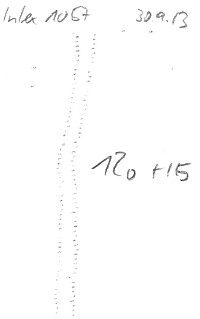

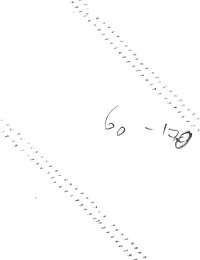

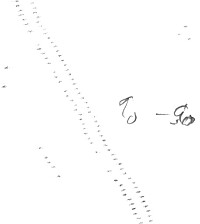

Horizontally, the movement was perfect, but on the vertical rates, it performed pretty bad:

crown right (12 up)

crown up (3 up)

crown left (6 up)

crown down (9 up)

dial up

dial down

| horizontal positions | |

|---|---|

| dial up | +-0 s/d |

| dial down | +-0 s/d |

| vertical positions | |

| crown right (12 up) | +15 s/d |

| crown up (3 up) | -70 s/d |

| crown left (6 up) | -170 s/d |

| crown down (9 up) | -90 s/d |

Technical data

| Manufacturer: | Intex |

| Caliber: | 1057 AUT SCD CLD |

| Size: | 11 1/2''' (measured: 24,3mm / 27,2mmmm) |

| A/h: | 18000 |

| Number of jewels: | 25 |

| Escapement: | Pallet lever |

| Balance types: | Nickel anular balance |

| Shock protection(s): | Farr II |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | no |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 2 holes |

| Features: |

|

| References: | Flume: 1962 - |