Description

1996 Seiko released the successor of the very popular caliber 7009A - the caliber Seiko 7S26A.

Technically, it was not a completely new construction, but more an evolution, especially for even more rationalization of the production.

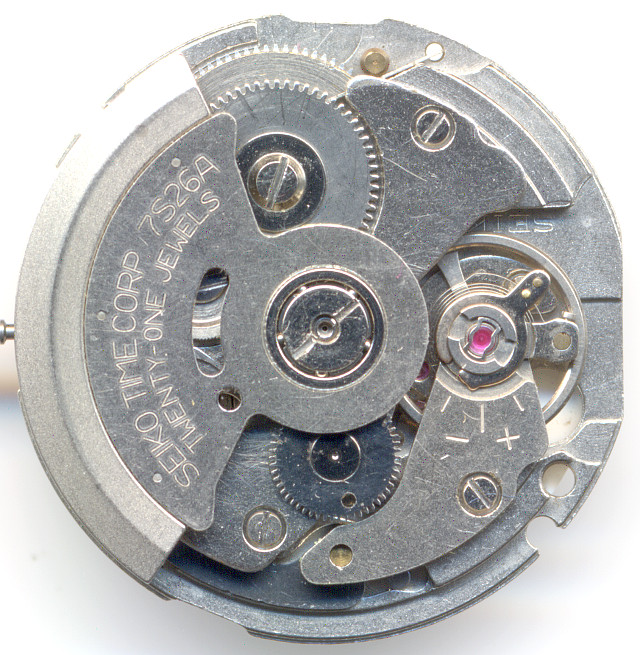

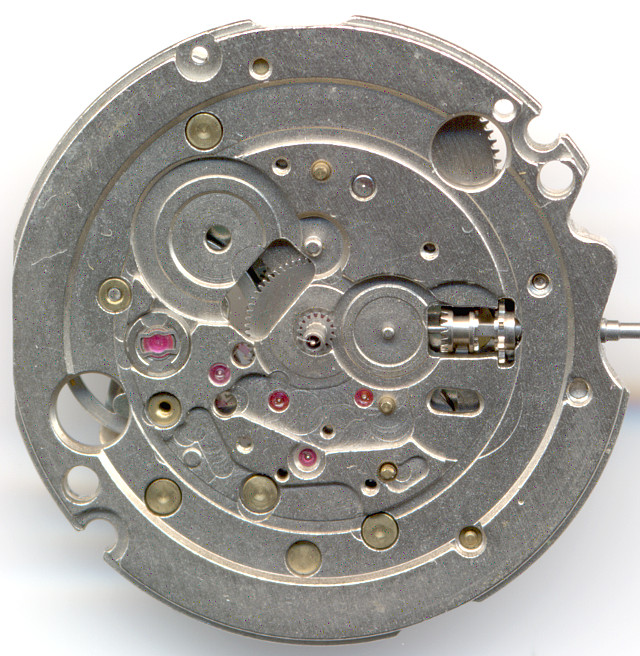

The base plate of the 12 ligne movement already shows, that it doesn’t belong to haut horlogery, but it is a well made, cost-efficient and long lasting movement.

All bearings, except of the mainspring barrel, contain jewels to not only increase the precision, but also the lifetime. The crown mechanism of the 7S26A is not on the dial side, but on the movement side. As you can see, it’s not the most beautiful one. It’s typical for Seiko selfwinding movement to leave out a manual winding function, although there are three setting positions. On position 2, date and weekday can be corrected and on position 3, the time can be set. There’s no hacking function.

The movement construction is uncompromising classical with its massive center minute wheel, which is directy driven by the mainspring barrel. Actually, these constructions were out-of date since the 1960ies, but if you primarily care for longevity, it is still a very good choice.

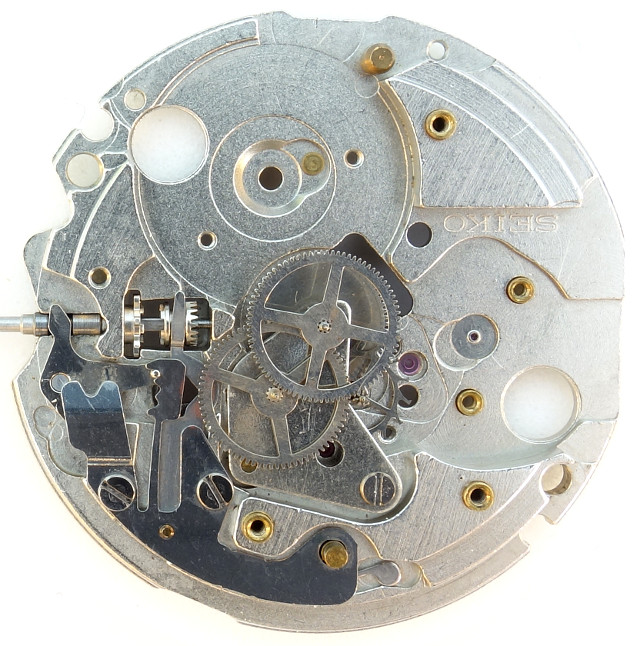

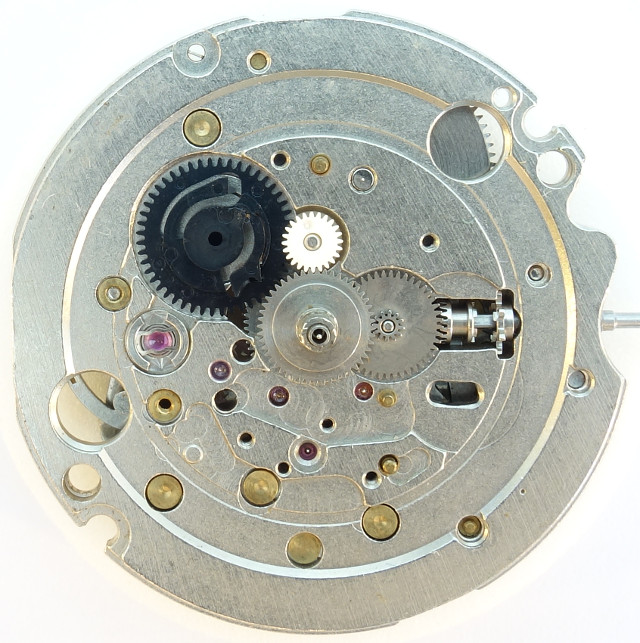

Consequently, the gear train itself is also a classic construction, with directly driven center seconds. The design of the wheels is clearly geared towards durability and low-cost manufacturing, rather than beauty.

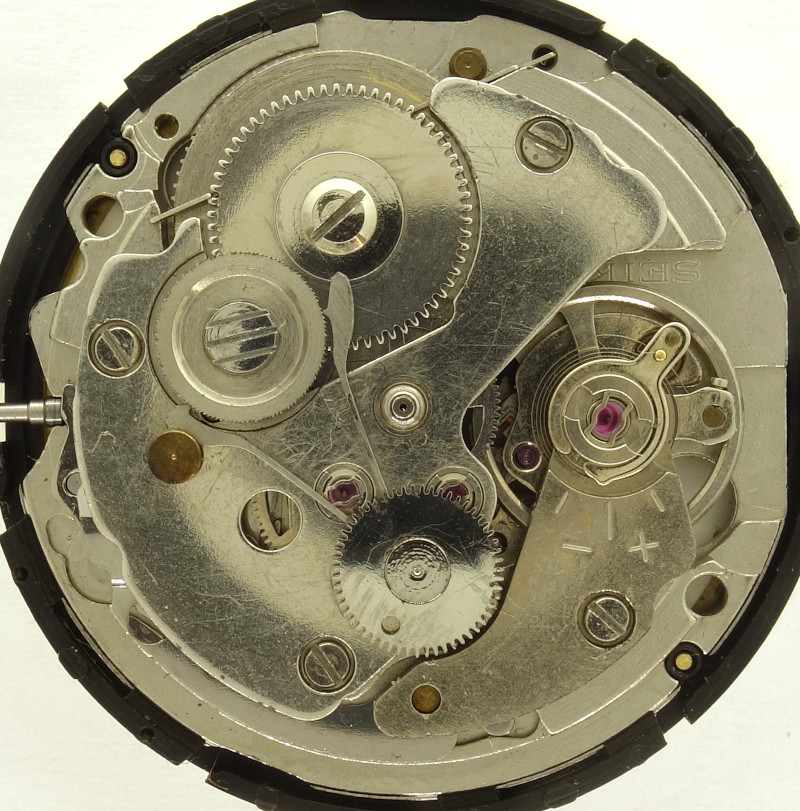

The anular balance of the 7S26A has got two waisted legs and is beared in two inhouse Diashock bearings of elongated type. It beats with 21600 A/h and regulares a classical swiss pallet lever movement.

It’s noteable, that on this movement, escapement wheel and third wheel contains cap jewels, beared in Diafix shock protections. This is the optimum, since the gears are not only shock protected, but have a very good oil reservoir.

On the inner side of the gear train bridge, you can see the bearing of the excenter wheel of the selfwinding mechanism. Its very long axle reaches until the bottom jewel on the base plate.

As usual on Seiko, also this movement uses the “Magic lever” excenter winding mechanism. The bearing of the excenter fork is on the lower side of the driving wheel, which is turned in both directions by the oscillating weight. Both pawls engage with the reduction wheel. Due to the sawtooth cut of that movement, one pawl slips, while the other turns the wheel - always in the same direction, counter-clockwise.

It is important to mount the magic lever correctly, because otherwise, it loses its function.

Since the 7S26A does not offer a manual winding function, the screw of the mainspring barrel is strengthened, so that the movement can be wound with a screw driver.

The ratchet is again a very simple construction, consisting of only one flat spring, which engages with the ratchet wheel.

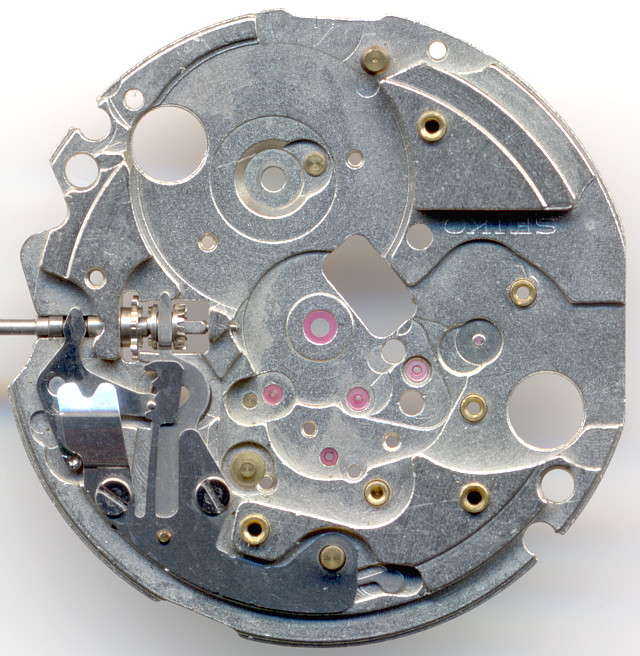

On the empty dial side, you can see the pressed pillars, which on the dial side, secure the screws of the bridges. You can also spot the preparations for the calendar mechanism.

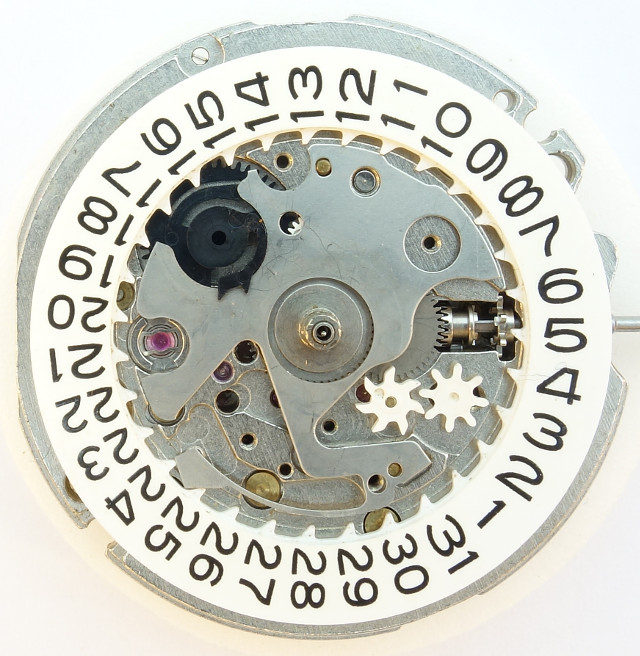

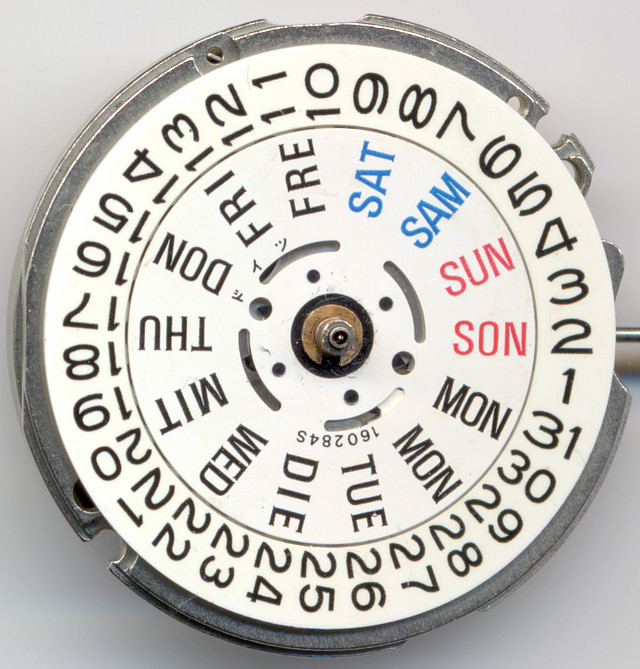

The calendar mechanism is driven by the hour wheel and consists of a plastic transmission wheel and a plastic switching wheel with two pawls, which advance the date ring as well as the bilingual weekday disc. At 10 pm, the date starts to slowly advance, at midnight, after it reaches the next day, the weekday slowly advances until 4 o’clock. It has to be advanced two positions due to its bilinguarity. On the second crown position, date and day can be corrected quickly and it’s also possible to change the language of the weekday indication.

The cover plate has got an integrated spring, which secures the position of the plastic date ring.

At 4 o’clock there are the two wheels, which are responsible for the quickset feature. The wheel on the right is moveable beared and enages, depending on its direction of rotation either with the gears of the date ring or with the left plastic wheel, which engages with the weekday disc.

The quickset mechanism is driven by a riveted wheel on the inner side of the second cover plate. This wheel is driven by the crown. The cover plate also contains a spring, which secures the position of the weekday disc.

The Seiko 7S26A has got no holes for mounting the dial feet. This is now achieved by a (not shown) plastic movement encasing ring, which surrounds the movement. At 1:30 and 7:30, there are two sockets, which then hold the dial feet.

In the lab

Timegrapher result

Before the movement was tested on the timegrapher, it was adjusted a little bit, since it ran pretty slow. Afterwards, the results were very good, especially, since there movement got not revision and was not in a really good shape:The low amplitude (even for Seiko conditions) shows the need for a revision. On the other hand, you can imagine, how well this movement will run if it is new or in good condition.

| horizontal positions | |||

|---|---|---|---|

| dial up | +33 s/d | 184° | 0.3ms |

| dial down | +12 s/d | 209° | 0.0ms |

| vertical positions | |||

| crown right (12 up) | +3 s/d | 175° | 0.0ms |

| crown up (3 up) | 0 s/d | 168.6O=-17° | 0.1ms |

| crown left (6 up) | s/d | ||

| crown down (9 up) | +8 s/d | 169° | 0.5ms |

Technical data

| Manufacturer: | Seiko |

| Caliber: | 7S26A |

| Size: | 12''' (measured: 26,8mm) |

| lift angle: | 53° |

| Number of jewels: | 21 |

| Escapement: | Pallet lever |

| Balance types: |

Nickel anular balance |

| Shock protection(s): |

Diashock (Seiko) |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 1 hole(s) |

| Features: |

|

| Production period: | 1996 - |

| Inventory number: | 17046 |