Description

Although it appears completely unsuspicious at first glance, the 13 ligne Rego 147 is a true chronograph movement on which, different to many mock chronograph, not the whole movement is stopped, but only the chronograph hands. And they can even be resetted.

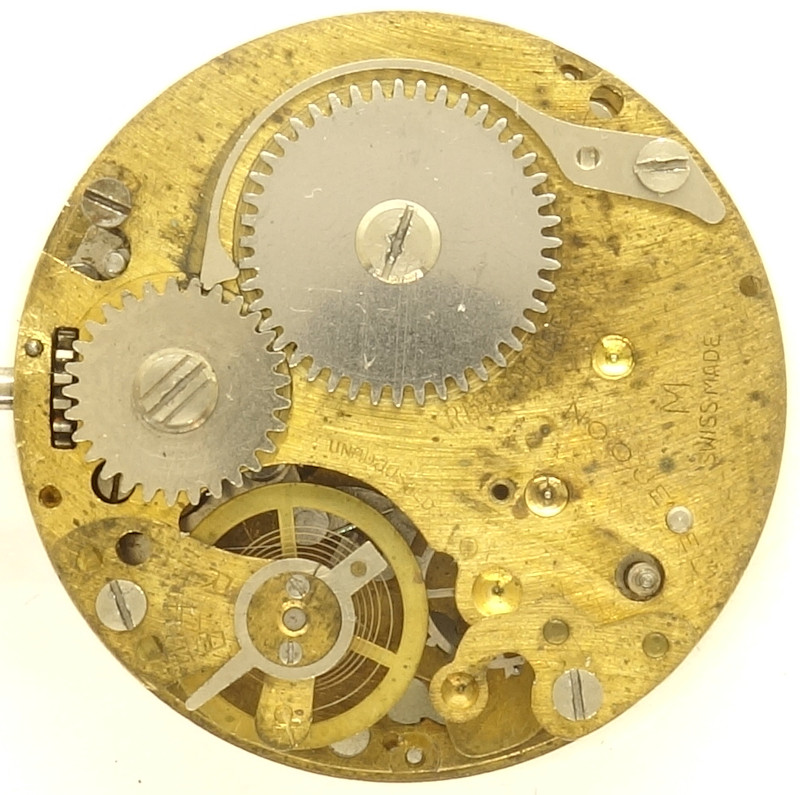

When the transmission lever for the resetting mechanism is removed, the movement looks like a normal pin lever movement.

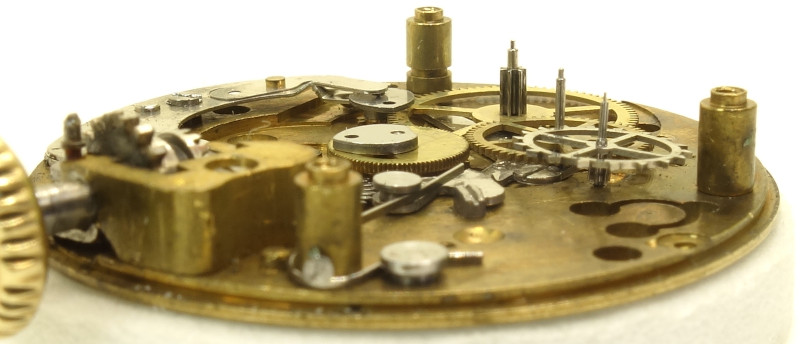

The transmission lever has got an integrated, riveted spring, which shall ensure, that when the “stop” button is pressed the first time, the lever “falls” down and can be moved on the second press of the “stop” button.

Sounds complicated and doesn’t work reliably.

The movement is a simple Roskopf pillar construction without any jewels.

Some axles, mostly for the stopwatch mechanism are riveted and not (or not without damage) releaseable from the base plate.

The lever works of the stopwatch mechanism cannot be removed as well. It attaches the seconds wheel (which turns counterclockwise on a Roskopf movement) with the center stop seconds wheel, or releases it.

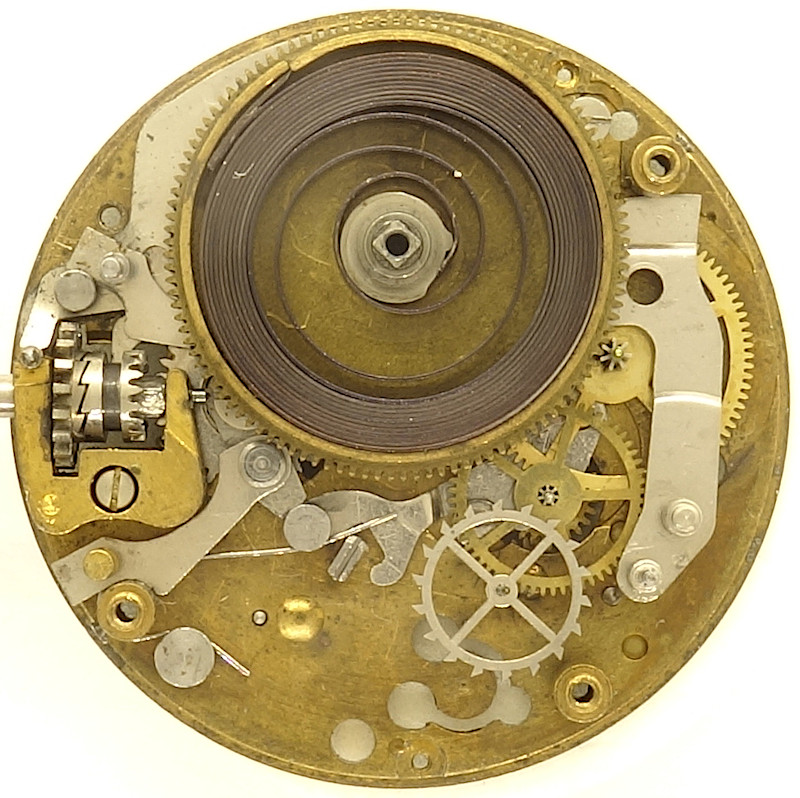

As common for a Roskopf movement, the large mainspring barrel overtops the center of the movement. The stop seconds wheel in the center is not beared on the movement side and thus riveted with the center seconds arbor, so that it cannot slip away.

Except the stopwatch mechanism, the gear train is the common one for a Roskopf movement: The mainspring barrel drives the very large second wheel, followed by the third wheel and finally the steel escape wheel with 18 teeth.

This construction allows, to save one reduction step.

The depthing of the pin lever can be adjusted by bending(!) the u-shaped cutout bearing.

The Rego 147 uses a screw-less three-leg anular balance, which is of course not shock protected. It beats with 17280 A/h, which is the common beat rate for a Roskopf movement. For adjustment purposes, a long regulator arm is used.

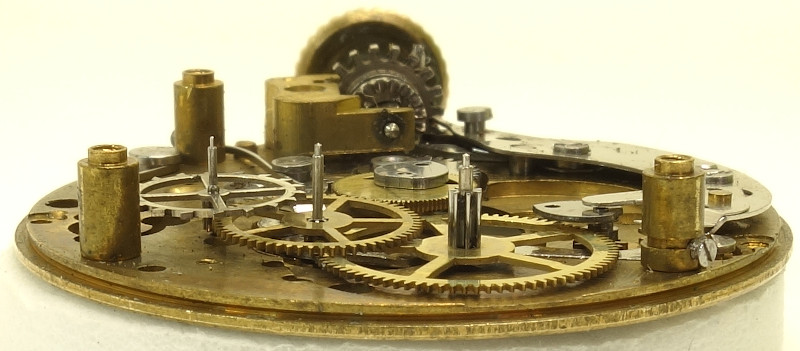

In the side view, you can see, how the seconds wheel engages with the center seconds stopwatch wheel.

For decoupling, the lower (on the base plate) bearing is shifted a bit to the outer edge, letting it beared a bit skew. A shirt-sleeved, but efficient solution.

The stopwatch minute wheel is connected directly with the mainspring barrel, and, if the stopwatch is stopped, is braked by the double lever (on the last image at 1 o’clock, but normally further engaged, almost at the axle), which presses agains the stop heart and thus stops the force-sparse slipping clutch of this wheel.

Due to the manufacturing tolerances, this does not work really reliably, sometimes, the wheel is stopped to early, sometimes too late.

When the stopwatch works, this construction leads to a funny situation, that when you adjust the time on the Rego 147, the stopwatch minute hand will also be corrected, since both, the time indicator hands and the stopwatch minute hand are driven from the same clutch on the mainspring barrel.

Unfortunately, the reset mechanism cannot be photographed, it also doesn’t work reliably and has to be executed multiple times.

Generally, the chronograph is started by pressing the lower button, and stopped by pressing the upper one.

Now, you have the choice to either start the chronograph again by pressing the lower button, or to reset it pressing the upper button (with a little luck, the hands go back to zero).

With the lower lever (at 4 o’clock, seen from the dial side), the stopwatch mechanism is started. The lever of the seconds wheel falls upwards, until it stops (adjustable with the almost rectangular screw at 7 o’clock) and engages the seconds wheel with the chronograph center seconds wheel.

By pressing the upper lever (2 o’clock, seen dial side) the seconds wheel lever is pressed into its starting position, like on the photo, and the center seconds wheel is decoupled from the seconds wheel.

If in this position, the reset lever, whose axle is the upper one of the two pins at the lower end, is pressed against the outer edge of the movement, the lever, which is beared, at 2 o’clock, in a slot of the pillar, falls towards the middle, until it resets the two stop hears, as to be seen on the photo.

On the yet empty dial side, you can see the two gears on the

mainspring barrel, which are connected with out by a slipping

clutch and synchronously drives both minute- and hour pinion.

Because of that an own exchange wheel is not required.

Interestingly, the Rego 147 uses already a yoke keyless works, which can be seen at 3 o’clock. The setting lever is mounted on the inner side and held in position by a flying beared spring. The assembly of this spring, which resides under the large metal cover, makes every watchmaker curse!

The balance wheel bearing is covered with a metal plate only.

At 7 o’clock, you see the bearing of the decentral second hand. This hand is driven by the moveable seconds wheel at 8 o’clock.

Conclusion

As interesting as this work may appear, technically it is it’s a nightmare because the manufacturing tolerances are so gigantic that it is practically impossible to ensure a perfect function.

No wunder, that this movement with its reset mechanism is rare to find, and was problably only made for a short time. Its companion, with 6-hour-subdial at 8 o’clock and without reset mechanism is much more convenient, but

Kein Wunder, dass dieses Werk mit seinem Rückstellmechanismus nur selten zu finden ist, und vermutlich nur kurze Zeit gebaut wurde. Sein Pendant mit 6-Stunden-Hilfszifferblatt auf 8 Uhr und ohne Rückstellmöglichkeit ist dagegen ungleich öfter zu finden, but that’s not a real chronograph then.

Technical data

| Manufacturer: | Rego |

| Caliber: | 147 |

| Size: | 13''' (measured: 29,4mm) |

| A/h: | 17280 |

| lift angle: | 38° |

| Escapement: | Pin lever |

| Balance types: |

monometallic anular balance (three legs) |

| Shock protection(s): |

none |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | no |

| Adjust mechanism: | Long regulator arm |

| Construction: |

|

| Construction type: | pillar construction |

| Winding mechanism: | yoke winding system |

| Features: |

|

| References: |

Feilner: 49 5147 Flume: 1957 52 |

| Inventory number: | 21027 |