Description

The large (11 1/2 lignes) mens’ movement EB 8135 was launched in the mid 1960ies and was an inexpensive, but functionally equal pin lever alternative to the otherwise use pallet lever movements. Some construction details are unusual, others costly, some very simple and genious.

The first noteworthy thing on this movement is, that it uses ruby bearings almost everywhere - at last in the version shown here. There exists also cheaper versions with less jewels.

Even better is, that all rubies are functional and not only used as cap jewels. Except the balance cap jewels, you won’t find any other cap jewels.

The gear train construction is a mix between a Roskopf movement (the hands are driven by a wheel on top of the mainspring barrel on the dial side only) and a conventional (pin-)lever movement with a mainspring barrel not overlapping the center of the main plate.

The indirect center second is driven by the third wheel.

There’s no ratchet mechanism, since it’s part of the selfwindig mechanism.

The very flat and light, probably stamped, annular balance is beared in two Novodiac shock protection systems and beats slowly with 18000 A/h. The mainspring is attached to a typical EB-type moveable stud.

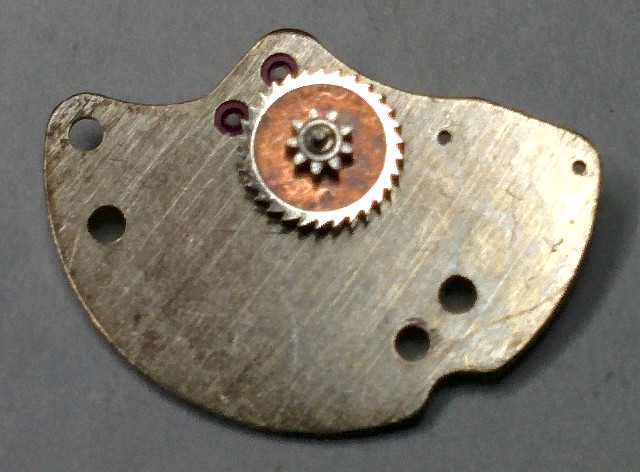

This pin lever regulates the movement. Without the mounted selfwindig mechanism, it looks this way:

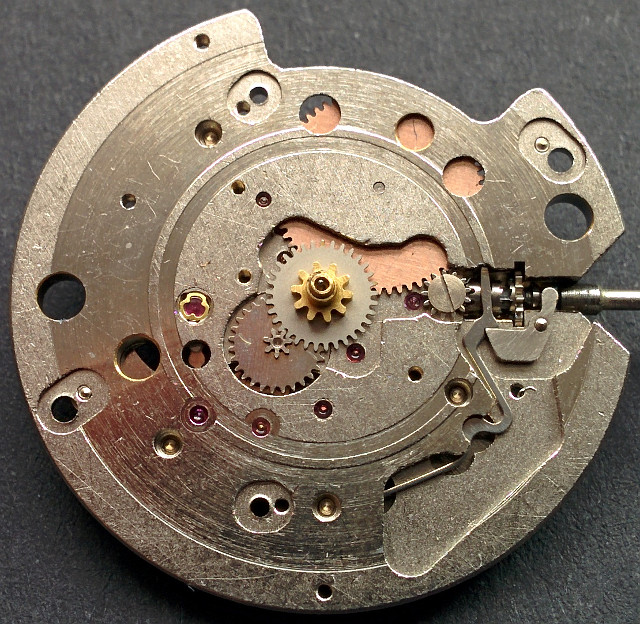

A real speciality is the construction of the selfwinding mechanism. It is as simple as genious:

The oscillating weight is connected to a coupling gear of the Harwood type, which, in connection with a pawl ensured, that it winds only in one direction and spins freely in the other one (and when hand wound, too). The coupling gear consists of only two parts: A gear with sawtooth dents inside (odd number of teeth) and a place with two pins, which blocks or slips inside, according to the direction:

The power transmission on the two-stage reduction gear happens by the tiny gear, which is fixed on the lower side of the blocking wheel.

In the two ruby bearings at 10 and 11 o’clock, there’s the pawl and spring, which are missing on the movement shown here. The reduction gears are beared in the two bearings at 3:00 and 3:30 o’clock.

On this photo, where the oscillating weight is missing, you can see, that the movement itself uses only a part of the main plate. This is due to the fact, that there’s a also a version with smaller diameter (8 3/4 lignes) of that movement. For EB this was a cheap way to produce both. Unfortunately, it’s a lot of space which remains unused and could otherwise improve the movement.

When the date indication mechanism is not mounted, you can spot the Roskopf construction, where the hands are driven by a coupled wheel on top of the mainspring barel. This wheel is connected to the yoke winding system, too. The changing wheel (at 8 o’clock) is not typical for Roskopf, but for a standard lever movement.

The date indication mechanism is pretty genious and consists of only six parts, a plate, a spring, two levers, a gear and a cam. And it’s hard to believe, but when you mount it lying on the bottom, it is really easy to mount.

The cam at “9”, here shown without the gear which is attached to it, ensures, that the date instantly changes at midnight. A semi-fast correction is possible by moving the hands between 21 and 24 o’clock.

In the lab

Technical data

| Manufacturer: | EB |

| Caliber: | 8135 |

| Size: | 11 1/2''' (measured: 26,0mm) |

| A/h: | 18000 |

| lift angle: | 49° |

| Number of jewels: | 21 |

| Escapement: | Pin lever |

| Balance types: | Nickel anular balance |

| Shock protection(s): | Novodiac |

| Balance bearing / direction hairspring: | Clockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Features: |

|

| References: | Flume: K3 170 |

| Data sheet: | 1969, 1971 |