Description

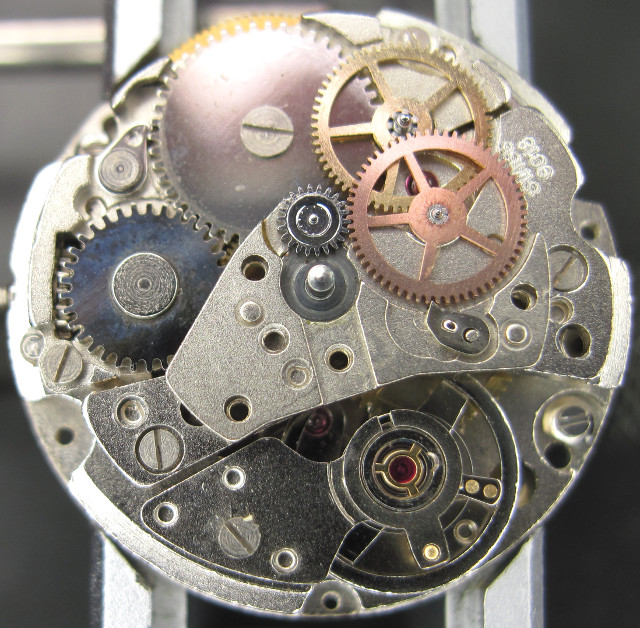

Somewhen in the late 1970ies, one of the last and best selfwinding pin lever movements, the caliber Ronda 9018, made in Lausen, Switzerland, was released. If you see it, you wouldn’t guess, that it is “just” a cheaper pin lever movement, as it absolutely reminds of a true “better” pallet lever movement.

Video on YouTubeWith a diameter of only 8 3/4 lignes, less than 20mm, it is not only one of the very few pin lever movement with a diameter of less than the ubiqutuous 10 1/2 lignes, but together with another caliber by EB, it is the smallest selfwinding pin lever movement, ever made.

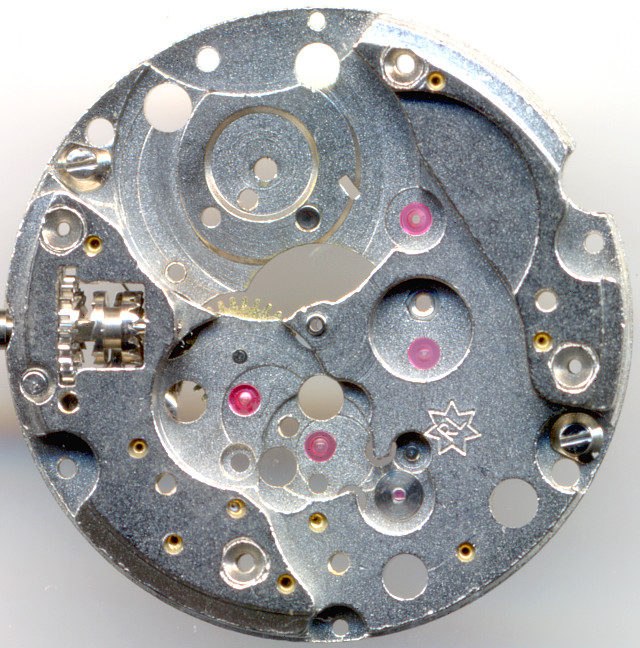

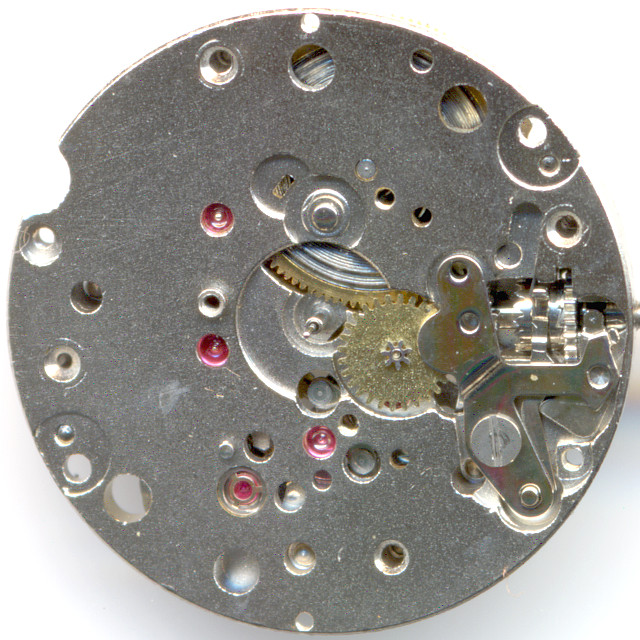

The base plate alone is very nice, since it isn’t just a pillar construction but massively made, and all bearings, except those of the mainspring barrel and the center second contain rubies.

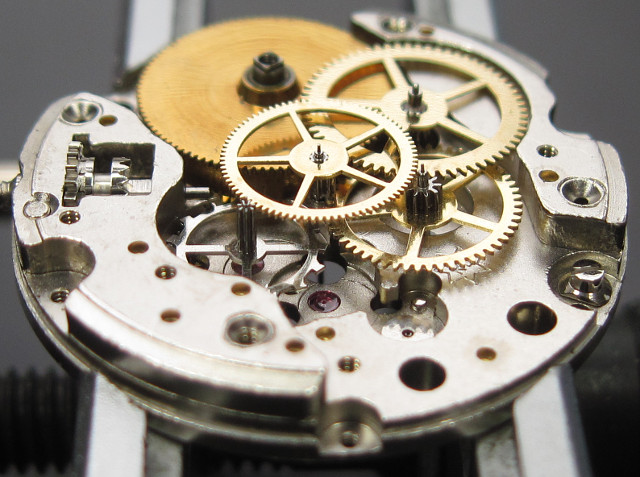

The gear train is very modern, with directly driven center second and an indirectly driven minute pinion. The four movement gears are located under one single bridge, where the rubies are pressed into rectangle-shaped holes. Not a very nice solution, but certainly very much cost-efficient.

The two shock protection bearings (with three legs) bear the screw-less annular balance, which beats with 21600 A/h.

The gear train is made in a way, that it could also be regulated by a pallet lever, and there even existed that version, as Ronda 9038.

The Ronda 9015 is its relative with manual winding only.

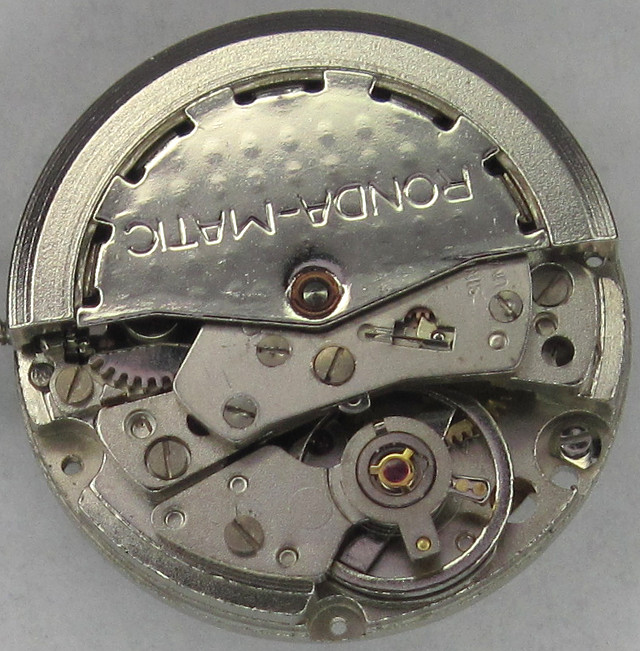

The selfwinding mechanism consists of two large reducing wheels, of which the first one is locked by a pawl against backwinding. There’s an additional moveable exchange wheel, connected to the oscillating weight, which is responsible, that during manual winding, the oscillating weight is decoupled, and under normal circumstances, the oscillating weight winds the movement in one direction only.

The oscillating weight is axle beared and locked by a flap at 6 o’clock.

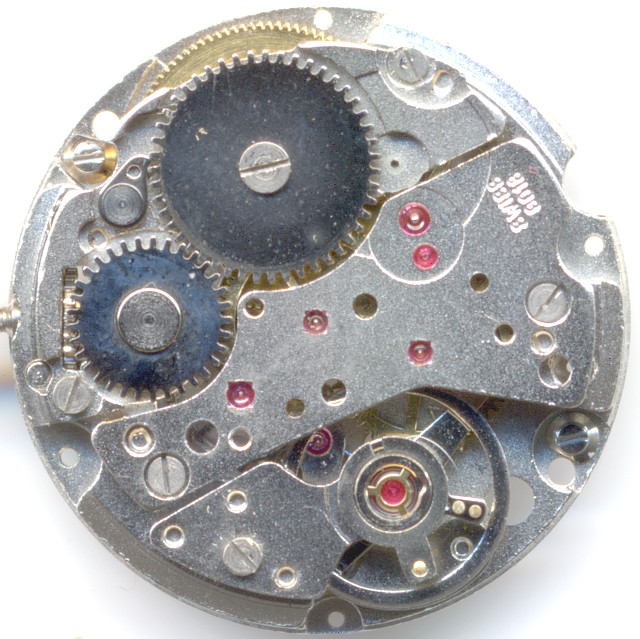

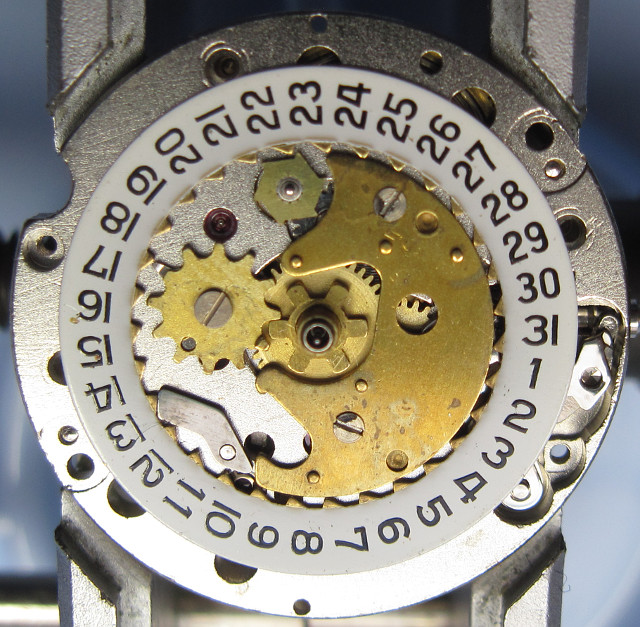

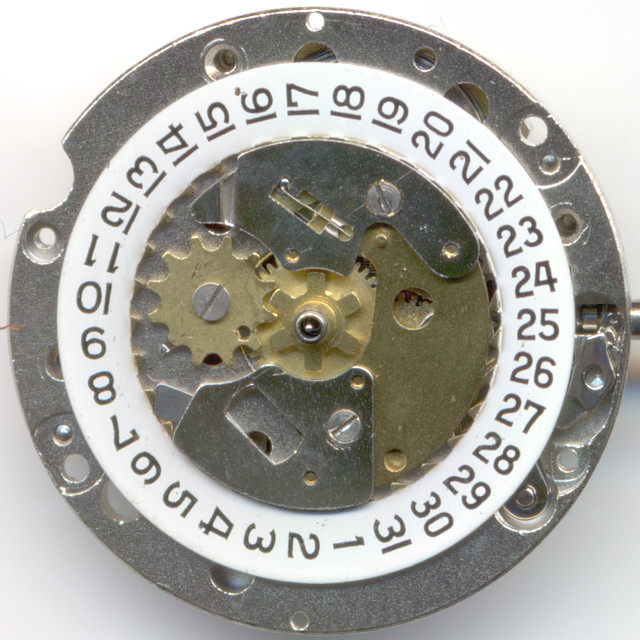

On the dial side, you see the yoke winding system and the open mainspring barrel, whose outer gear, which is connected to the mainspring barrel by a slide coupling, drives the minute wheel.

The Ronda 9018 uses an odd but very efficient date indication mechanism. The large switching wheel at 9:30 has got one longer tooth, which advances the date ring.

If you turn back the time, the ratchet at 11:30 drives the date ring forth, while the longer tooth of the switching wheel is moveable and doesn’t interfer here.

It’s a nice detail, that three of four springs on that movement are connected to the covering plates and so can’t fly away. You only have to hope, that they don’t break…

In the lab

On the specimen shown here, the oscillating weight was dissolved into two parts, since the outer weight is just plugged into the rotor plate. According to a crack in the crystal, a hard hit must have been responsible.

In the workshop, the oscillating weight was fixed and a full service was made. The rates are now very good, except in one position (see later):

For such a small pin lever movement, the rates are excellent! Only the rate "dial up" is a bit bad, but it's due to the hard shock described above, which also affected the balance, which now has got a noteable runout!

Timegrapher result

| horizontal positions | |||

|---|---|---|---|

| dial up | +46 s/d | 287° | 0.1ms |

| dial down | +11 s/d | 237° | 0.1ms |

| vertical positions | |||

| crown right (12 up) | +9 s/d | 257° | 0.5ms |

| crown up (3 up) | +11 s/d | 237° | 0.1ms |

| crown left (6 up) | +17 s/d | 254° | 0.2ms |

| crown down (9 up) | -1 s/d | 256° | 0.3ms |

Technical data

| Manufacturer: | Ronda |

| Caliber: | 9018 |

| Size: | 8 3/4''' (measured: 19,3mm) |

| A/h: | 21600 |

| lift angle: | 52° |

| Number of jewels: | 17 |

| Escapement: | Pin lever |

| Balance types: | anular balance |

| Shock protection(s): | ? |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 3 holes |

| Features: |

|