Description

The final series of mechanical gents movements by PUW was the caliber series 660/1660, which was only made between 1977 and 1979, at a time, when nobody was interested in mechanical watches any more.

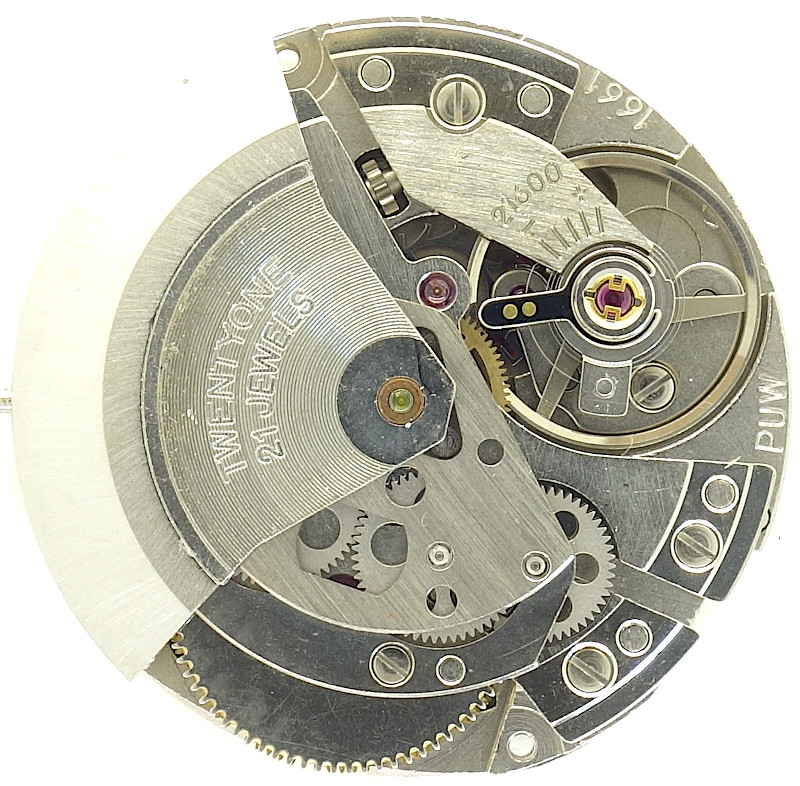

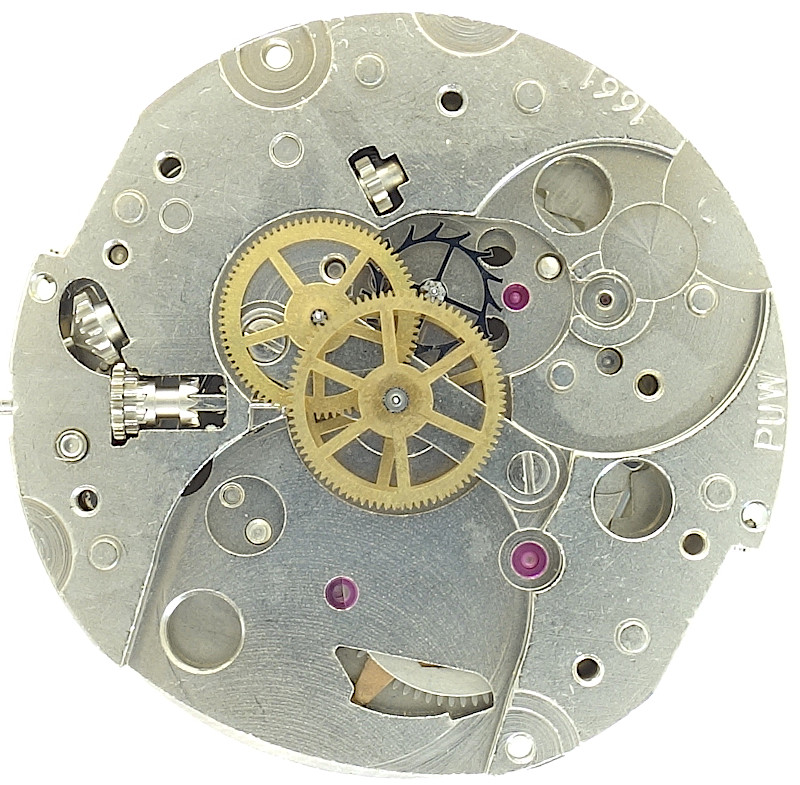

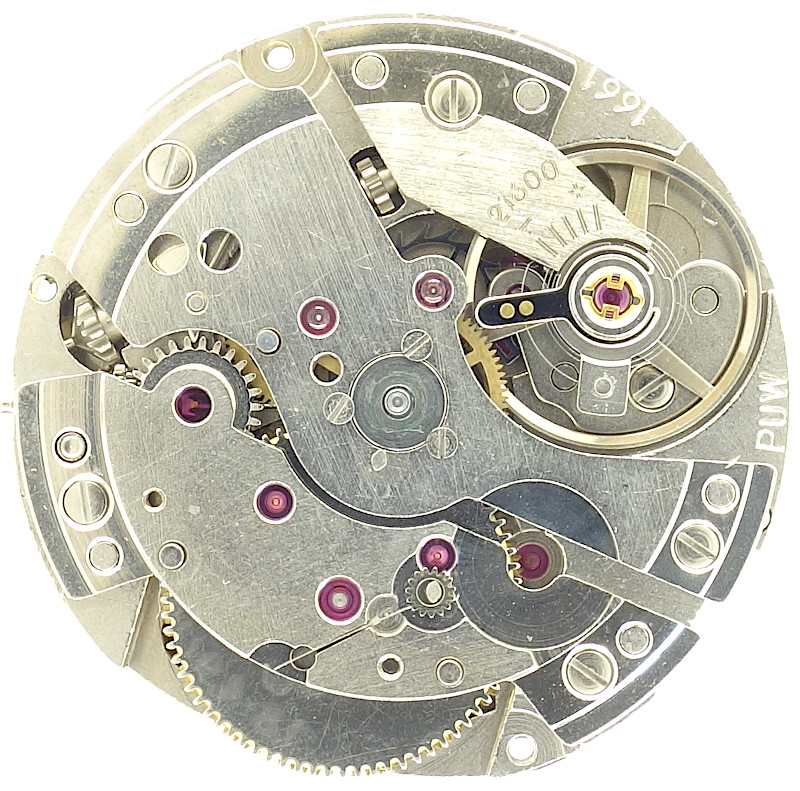

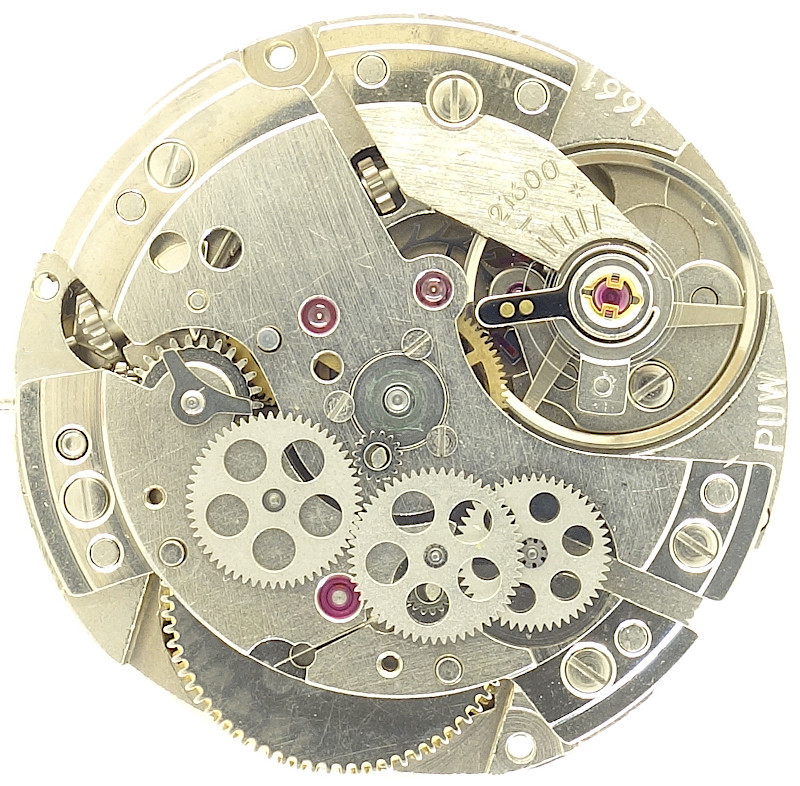

On this series, you can see some modern solutions, such as the date correcting mechanism, but on the other hand, there are several signs of cost cutting constructions like riveted wheels or a one-third oscillating weight.

The PUW 1661 was the selfwinding version with date indication; with a diameter of 11 1/2 lignes (25,6mm) it was at eye level with the common ETA movements at the time and it offered a date quickset mechanism.

It is self-evident that here all important bearings use rubies, except for the fact, that the minute wheel lacks a ruby, while the slower revolving mainspring barrel is beared is a ruby pair.

The construction with center minute wheel is a bit outdated, but on the other hand, it is proven and reilable, so that even today, many movements use a center minute wheel, driven by the mainspring barrel.

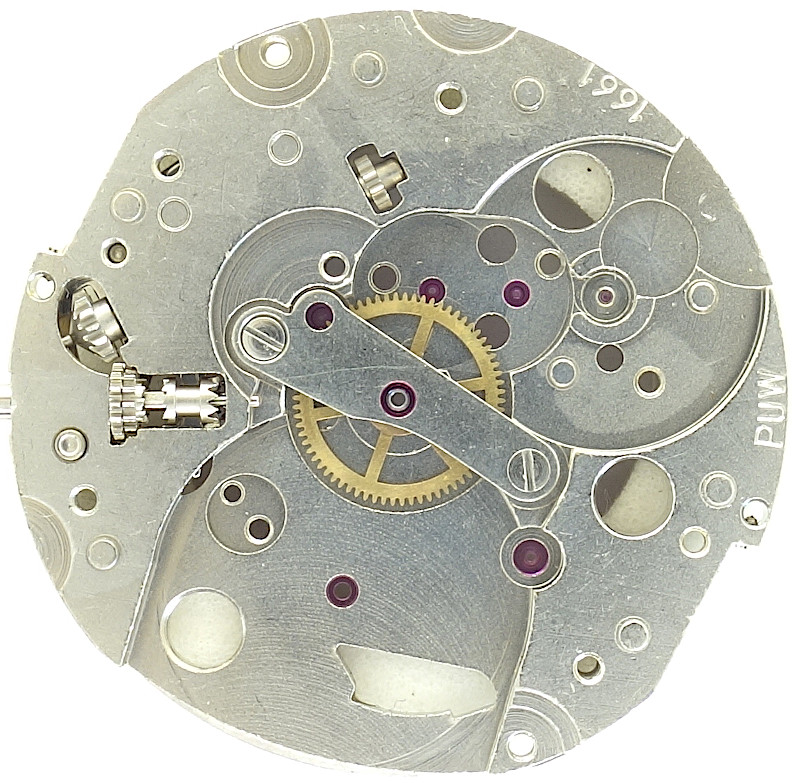

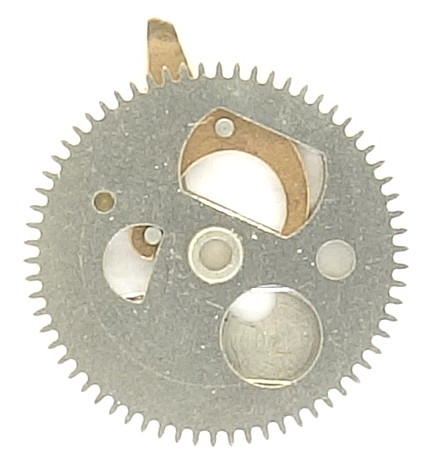

Speaking of the mainspring barrel: Below the barrel bridge there’s the riveted crown wheel. A cost-effcient but not very service-friendly solution.

As already indicated above, there’s the classical gear train: The large mainspring barrel drives the center minute wheel, followed by third wheel, center seconds wheel and steel escape wheel.

The modern three-leg anular balance is of course without screws, but shock protected (here in two RUFA Antishock bearings). It still beats rather slowly with 21600 A/h and won’t easily run within the chronometer specs. Since the adjustment is only possible at the hairspring key, the PUW 1660 sells below value.

The next riveted part is the ratchet, which is located on the inner side of the gear train bridge, as well as the associated u-shaped spring.

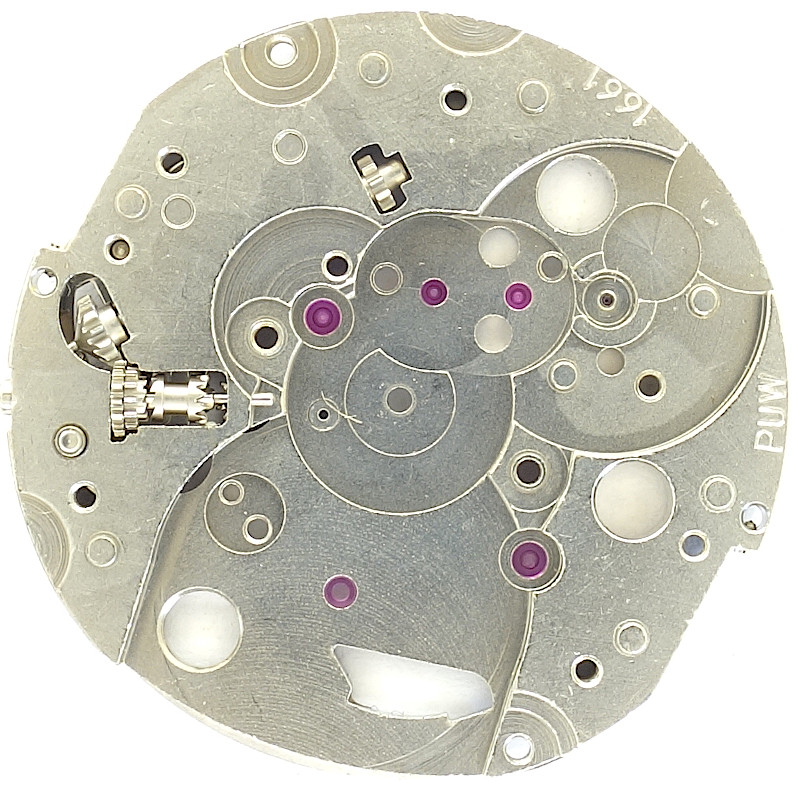

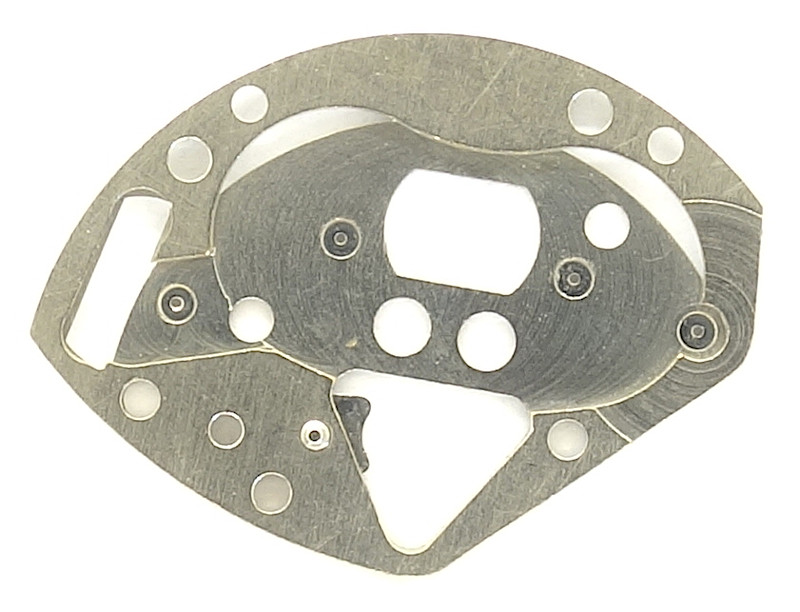

When the selfwinding mechanism is not yet mounted, you can see the nicely slanted shapes of the brigdes and also the locations of crown wheel and ratchet and how they interact.

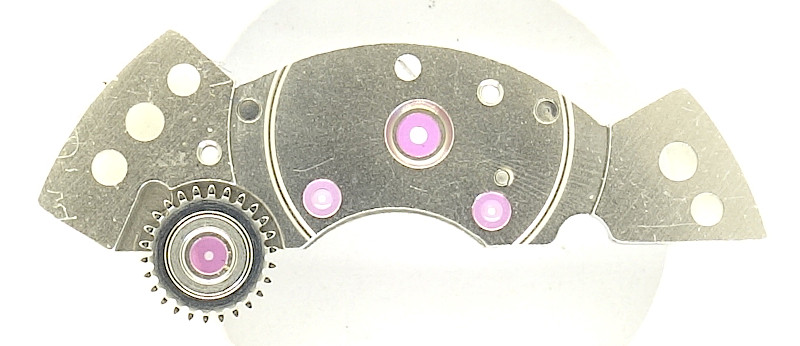

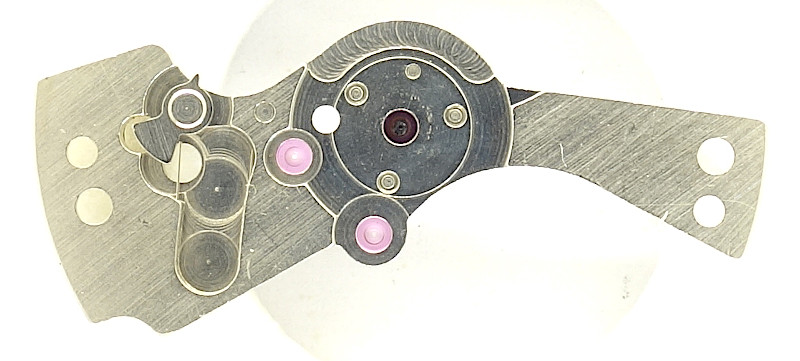

The axle bearing for the oscillating weight is mounted and secured by three screws on top of the gear train bridge.

The coupling of the first reduction wheel to the exchange wheels of the selfwinding mechanism is realized by a genious construction: Below the right exchange wheel, there’s a flying beared wheel, which is pushed by the selfwinding wheels onto the reduction wheel, so that it revolves. When, on the other hand, the movement is manually wound, the revolving of the reduction wheel achieves, that the flying beared wheel gets out of the powerflow and disengages the selfwinding mechanism.

The second flying beared gear engages with the oscillating weight and, depending on its direction of rotations, it engages with either the left or the right exchange wheel, which also interact. With that construction, the oscillating weight turns the right exchange wheel always turns on the same direction. The left exchange wheel is locked by a pawl to turn into the wrong direction.

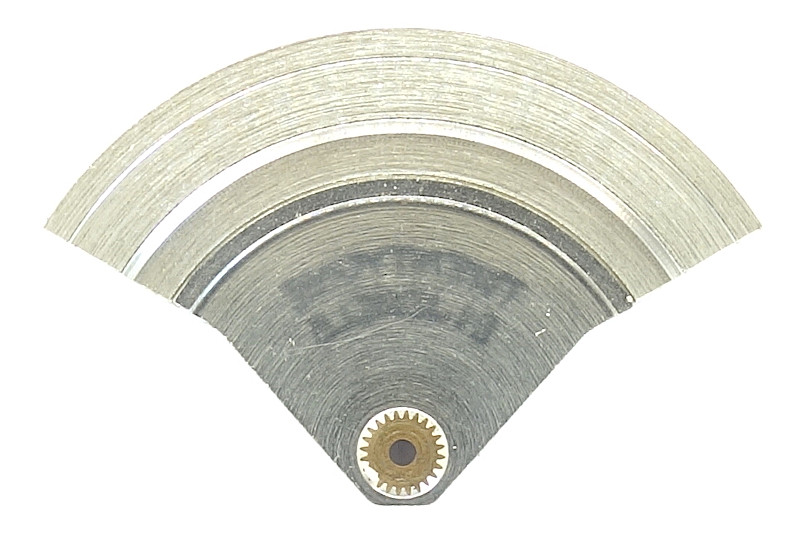

The dead angle of the selfwinding mechanism, the angle of the oscillating weight, where it does not wind due to the roation direction change, is pretty small with only about 45 degrees. Since the oscillating weight is only a third of a circle, the movement efficiently weights even on little movement.

Unfortunately, at the end of the 1970s, nobody cared anymore for this efficient and genious construction of a selfwinding movement. The upcoming quartz watches were much more interesting at that time.

For the first time at PUW, probably due to cost cutting reasons, a half circle shaped oscillating weight was replaced by a third circle shaped one. There was also no ball bearing, they remained with the axle bearing.

On the dial side, you can see the three-stage yoke winding system. In the middle position, the correcting axis, which lays between 12 and 3 o’clock is coupled in and drives the date corrector wheel at 12 o’clock.

The main part of the date indication is the switching wheel with its two fingers, one at the side, which builds up tension and the vertical pin, which engages with the date ring and advances it instantly at midnight.

The date switching wheel is driven by the hour wheel. The side finger is preloaded through appropriate recesses in the main plate so that it slips into the “release position” at midnight.

The two date correcting wheels are riveted with the flat bridge. The upper wheel can slide up and down and so advances in one direction the date wheel and in the other direction, it would advance the weekday, but this is a feature of the calibers PUW 663.

The date mechanism is covered with a flat plate and contains a spring-loaded lever, which engages with the date wheel, ensuring, that it always snaps into the correct position.

On the dial side, you can see at 11:30 o’clock the preparations for the weekday indication.

From its features and construction, the PUW 1661 was almost at eye level with the corresponding swiss movements, but unfortunately, it entered the market too late.

In the late 1970ies, even the highest featured mechanical movement had no chance against the popular quartz movements, except by offering very low prices. But such a high quality movement could not be offered at a very low price.

It’s sad, that this technically very interesting movement marked the end of the manufacturing of mechanical movements at the PUW. It deserved better.

In the lab

Timegrapher result

After the adjustment, this movement showed almost perfect results on the timegrapher, only a tiny bit outside the chronometer specification of -4…+6 seconds per day. You see, what an elaborate construction this final mechanical PUW movement was!| horizontal positions | |||

|---|---|---|---|

| dial up | 0 s/d | 287° | 0.0ms |

| dial down | +7 s/d | 263° | 0.2ms |

| vertical positions | |||

| crown right (12 up) | +1 s/d | 273° | 0.3ms |

| crown up (3 up) | -9 s/d | 264° | 0.0ms |

| crown left (6 up) | -1 s/d | 260° | 0.2ms |

| crown down (9 up) | +2 s/d | 259° | 0.0ms |

Technical data

| Manufacturer: | PUW |

| Caliber: | 1661 |

| Caliber base: | PUW 660 |

| Size: | 11 1/2''' (measured: 25,6mm) |

| A/h: | 21600 |

| lift angle: | 52° |

| Number of jewels: | 21 |

| Escapement: | Pallet lever |

| Balance types: | Nickel anular balance |

| Shock protection(s): | Rufa-Anti-Shock |

| Balance bearing / direction hairspring: | Counterclockwise |

| Moveable stud: | yes |

| Adjust mechanism: | Hairspring key |

| Construction: |

|

| Construction type: | solid construction |

| Winding mechanism: | yoke winding system |

| Setting lever spring: | 3 holes |

| Features: |

|

| Production period: | 1977 - 1979 |

| Inventory number: | 20034 |